Preparation method of gray/vermicular graphite composite cast iron material

A technology of vermicular graphite cast iron and cast iron, which is applied in the field of preparation of gray/vermicular composite cast iron materials, can solve the problems of conflict between strength and toughness and thermal conductivity, insufficient thermal conductivity, damage to diesel engines, etc., and achieve low cost, little environmental pollution, Effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] The preparation method of the coating is to first stir the bentonite suspension for 3-5 minutes, and then add FeS and phenolic resin to stir evenly.

[0024] The composition and preparation method of the vermicular graphite cast iron are common vermicular graphite cast iron and its smelting method in the national standard.

Example Embodiment

[0025] Example 1:

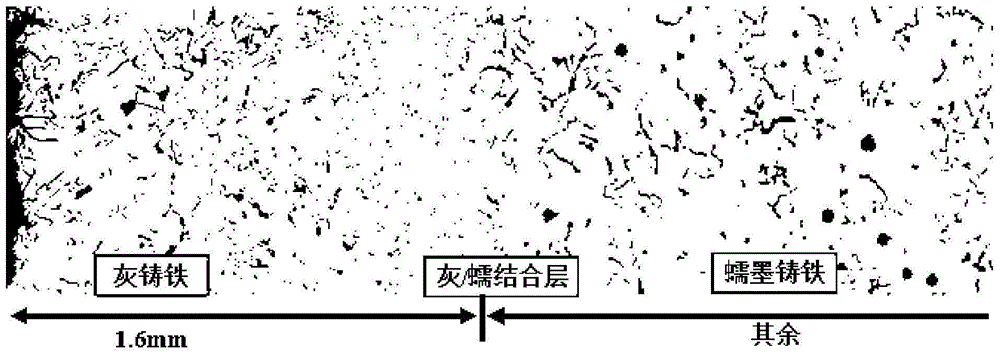

[0026] The composition of all coatings is commercially available industrial grade FeS: 5wt%, phenolic resin: 1wt%, and the balance is bentonite suspension. First mix the bentonite and water at a ratio of 1:1, stir well and place for 8 hours to make a bentonite suspension, and grind FeS into 80 mesh. Next, when the paint is configured, the bentonite suspension is stirred for 3 minutes, FeS and phenolic resin are added, and the mixture is evenly stirred for later use. Then apply 0.2mm FeS-containing paint on the surface of the partial mold of the casting, and dry it naturally for 8 hours. Pouring vermicular graphite cast iron (RuT300) at 1350°C, and after cooling and solidification, a 1.4mm gray cast iron is prepared on the surface of the casting, and the other parts are gray / compact graphite cast iron composite cast iron materials (see figure 1 ). From figure 1 It can be seen that the gray cast iron layer and the compact graphite cast iron layer of the gray / c...

Example Embodiment

[0027] Example 2:

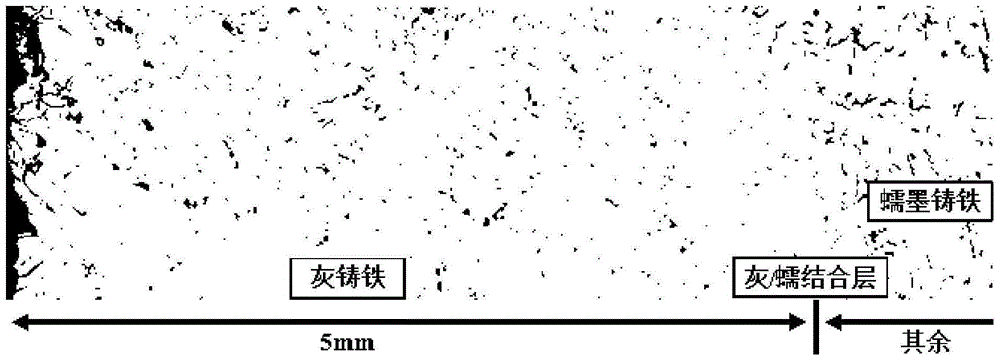

[0028] The composition of all coatings is commercially available industrial grade FeS: 15wt%, phenolic resin: 3wt%, and the balance is bentonite suspension. First mix the bentonite and water at a ratio of 1:1, stir well and place for 10 hours to make a bentonite suspension, and grind FeS into 100 mesh. Next, when configuring the coating, first stir the bentonite suspension for 4 minutes, add FeS and phenolic resin and continue to stir evenly before use. Then apply 0.5mm FeS-containing paint on the surface of the partial mold of the casting and dry it naturally for 10 hours. Pouring vermicular graphite cast iron (RuT300) at 1380℃, and after cooling and solidifying, prepare 5mm gray cast iron on the surface of the casting, and the other parts are gray / compact graphite cast iron composite cast iron materials of vermicular graphite cast iron (see figure 2 ). From figure 2 It can be seen that the gray cast iron layer and the compacted graphite cast iron layer o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com