Cr-containing high-strength constant-expansion alloy

A constant expansion, high strength technology, applied in the field of metal materials, can solve problems such as unsatisfactory alloys, achieve the effect of improving purity, ensuring stability, promoting technological progress and industrial development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

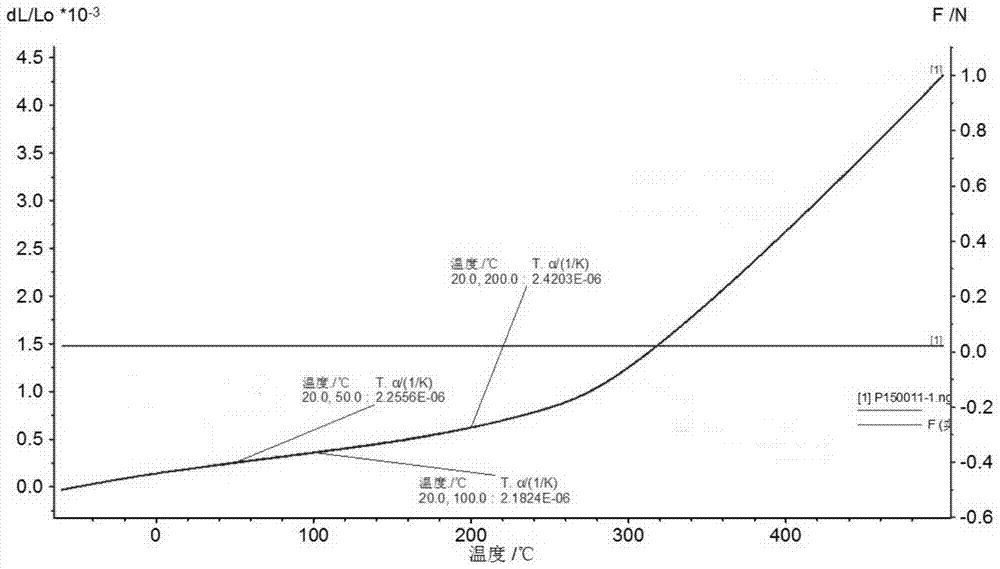

Image

Examples

Embodiment 1

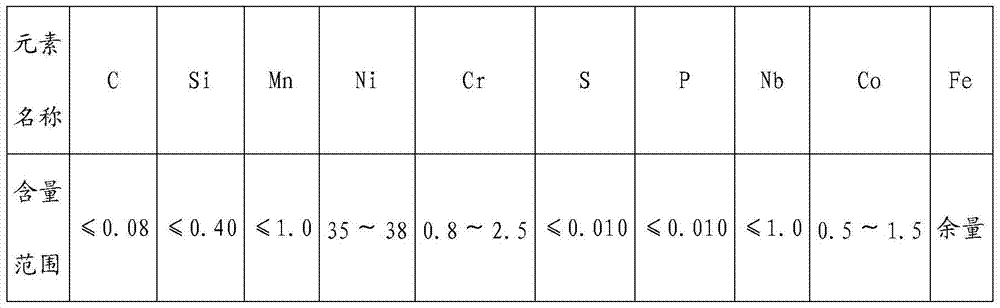

[0059] High-strength constant expansion alloy, its chemical composition is calculated by weight percentage: C: 0.03; Si: 0.10; Mn: 0.60; Ni: 35.0; Cr: 2.5; Nb: 0.8; Co: 0.8; the balance is Fe;

[0060] The preparation method of the above-mentioned novel high-strength constant expansion alloy comprises the following steps:

[0061] a) Melting

[0062] Each component is weighed according to the weight percentage of its chemical composition. The alloy adopts vacuum induction melting. When vacuum induction melting is carried out, a secondary refining process is adopted. The first refining temperature is slightly higher and the time is slightly longer;

[0063] first refining

[0064] Put the base materials into the furnace: Fe, Nb, Co, Ni, Cr, melt at a temperature higher than 1600°C, and control the vacuum degree of 15-25Pa, and melt at a time of 0.6min / kg;

[0065] second refining

[0066] The second refining adopts low-temperature short-time refining, puts C, Si, and Mn into...

Embodiment 2

[0079] High-strength constant expansion alloy, its chemical composition is calculated by weight percentage: C: 0.05; Si: 0.20; Mn: 0.50; Ni: 37.5; Cr: 1.0; Nb: 0.8; Co: 1.0; the balance is Fe, produced Alloy ingots are hot-worked and cold-worked into alloy materials, which are used in seals.

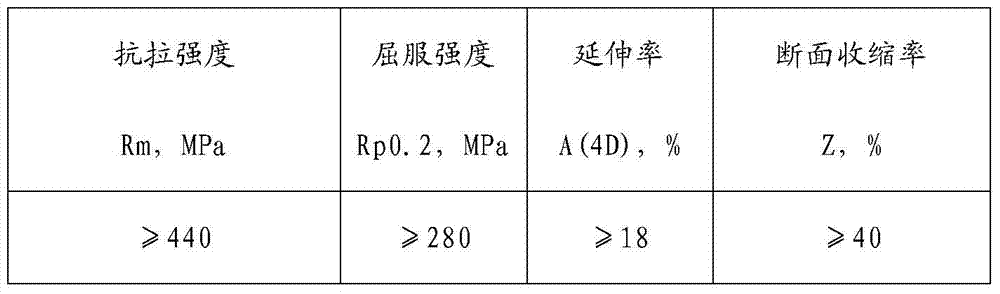

[0080] The preparation method is the same as in Example 1. The obtained samples were tested, and the performance test values are shown in Table 4:

[0081] Table 4 Example 1 sample performance test value

[0082]

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com