Spinning unhairing machine

A wool machine and dehairing technology, applied in the field of textile machinery, can solve the problems of incomplete dehairing, imperfect structure setting, poor dehairing effect, etc., and achieve the effect of ensuring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

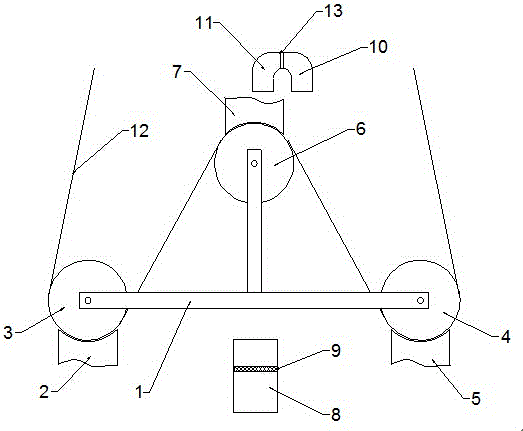

[0014] Such as figure 1 As shown, the present invention discloses a textile dehairing machine, which includes a pair of T-shaped supports 1, a roller arranged between the pair of T-shaped supports 1, a depilatory device and an air suction device.

[0015] A pair of T-shaped brackets 1 are arranged in parallel, the first roller 3 and the second roller 4 are respectively arranged at the two ends of the horizontal direction, and the third roller 6 is arranged at the vertical top; The arc-shaped hair-removing brush A2 and the arc-shaped hair-removing brush B5 at the bottom of the roller 4, the arc-shaped hair-removing brush C7 arranged on the top of the third roller 6; the suction device includes a suction fan A8 and a suction fan B13, and a suction fan A8 It is arranged at the bottom of a pair of T-shaped brackets 1, and a filter screen 9 is arranged inside the suction fan A8; the suction fan B13 is N-shaped, and is arranged on the upper end of the arc-shaped hair removal brush C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com