Loading force measuring device for slope model experiment and loading fixing method of loading force measuring device

A technology of model experiment and force measuring device, which is applied in the direction of basic structure test, construction, basic structure engineering, etc., can solve the problems of controlling the size of anchoring force, data error, and the influence of the overall stability of the model, so as to reduce data error, The effect of ensuring accuracy and ensuring completeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

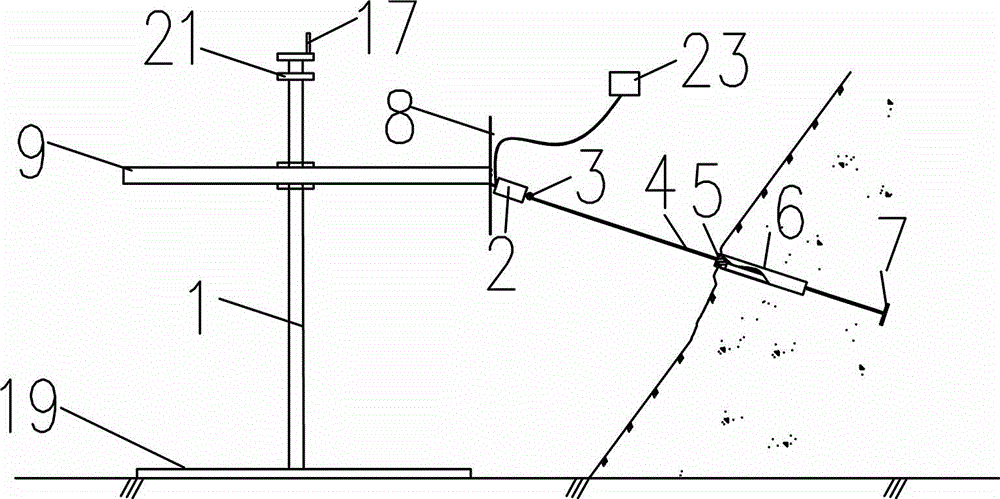

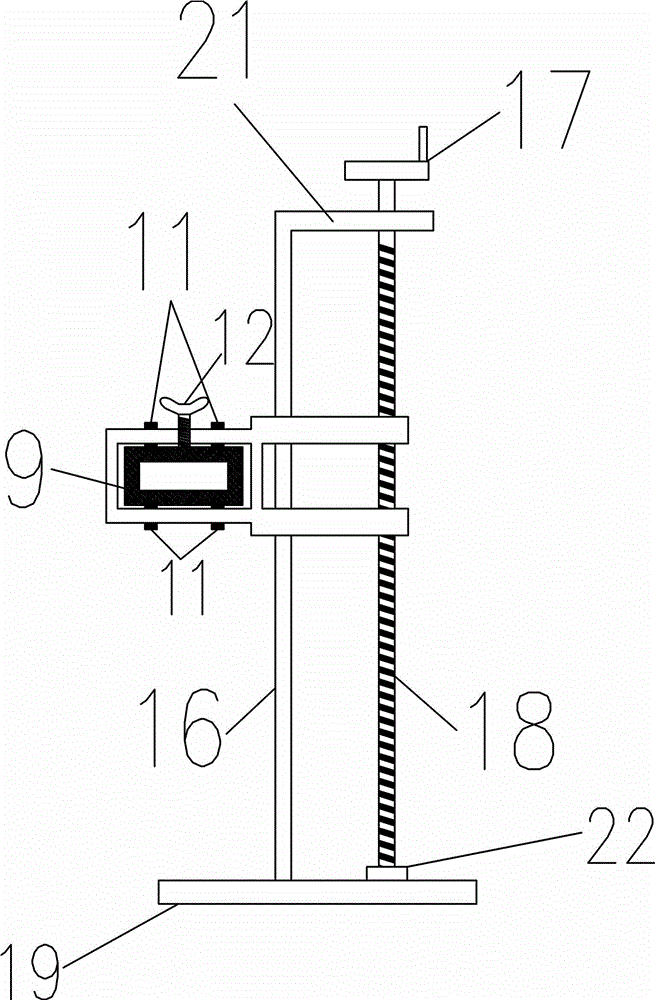

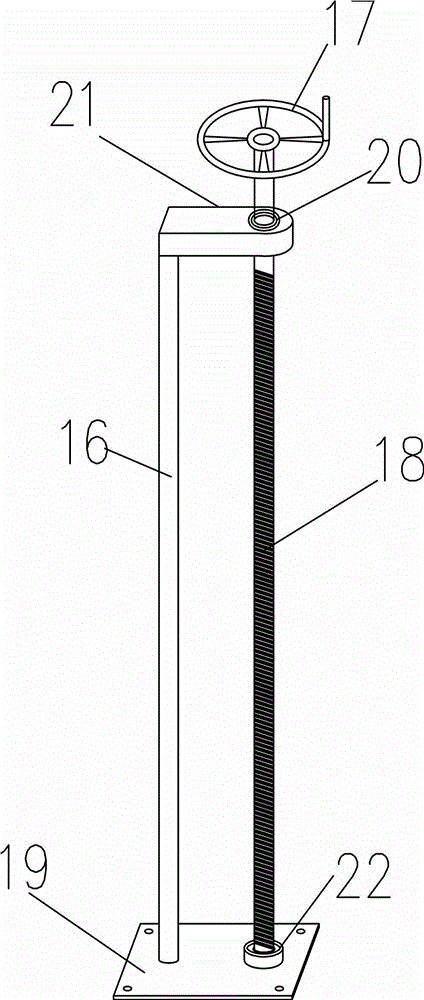

[0036] As shown in the figure, a load-measuring device for slope model experiments includes a bracket 1, and the bracket 1 is divided into a smooth rod 16 and a threaded rod 18, the smooth rod 16 and the threaded rod 18 are parallel to each other, and the smooth rod 16 and the threaded rod 18 are parallel to each other, the bottom end of the smooth rod 16 is fixedly arranged on the base 19, a horizontal plate 21 is provided between the smooth rod 16 and the top of the threaded rod 18, and a scale is provided on the horizontal plate 21;

[0037] The bottom end of the threaded rod 18 is connected to the base 19 through the second rolling bearing 22, the top end of the threaded rod 18 passes through the horizontal plate 21, the top end of the threaded rod 18 is provided with a turntable 17, and the position passing through the horizontal plate is provided with a first rolling bearing 20;

[0038] An adjustment platform is provided on the threaded rod 18 and the smooth rod 16, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com