Special circuit board bending resistance testing machine

A circuit board and testing machine technology, applied in the direction of strength characteristics, using a stable bending force to test the strength of materials, measuring devices, etc., can solve the problem that the circuit board cannot be separated, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

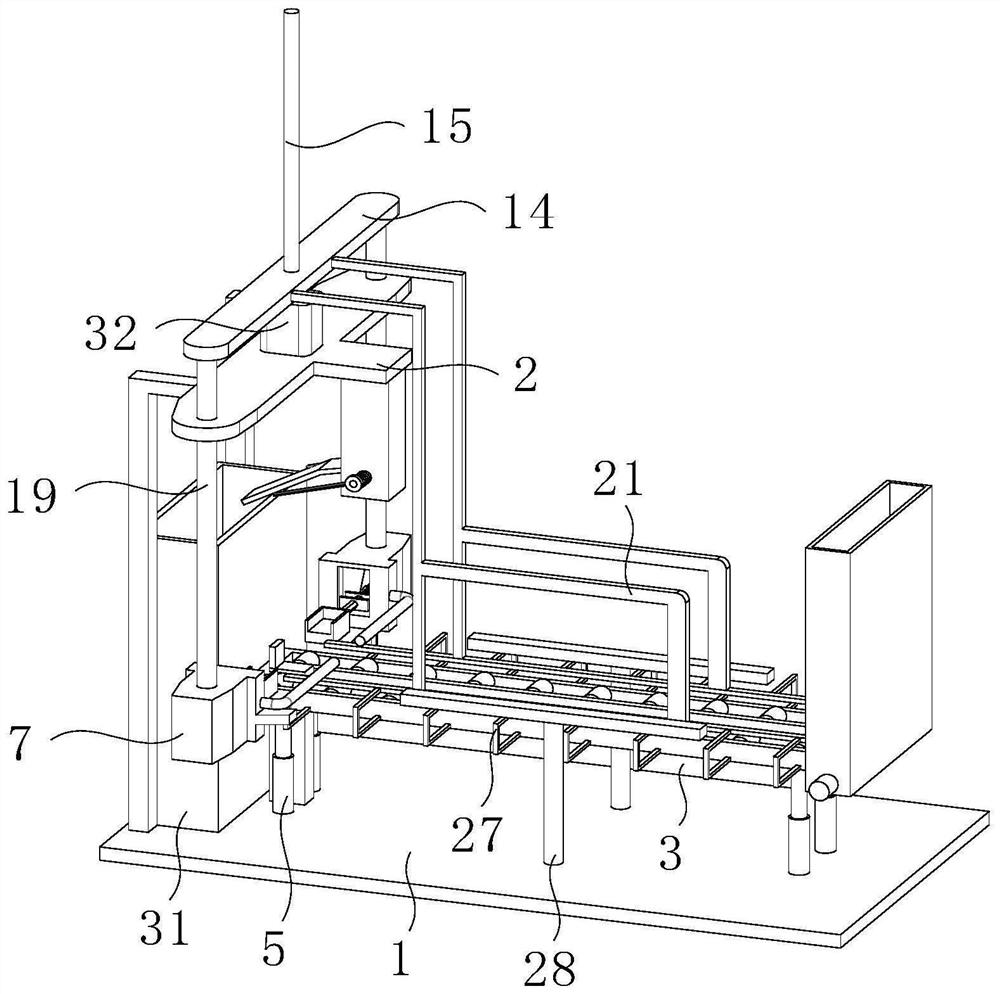

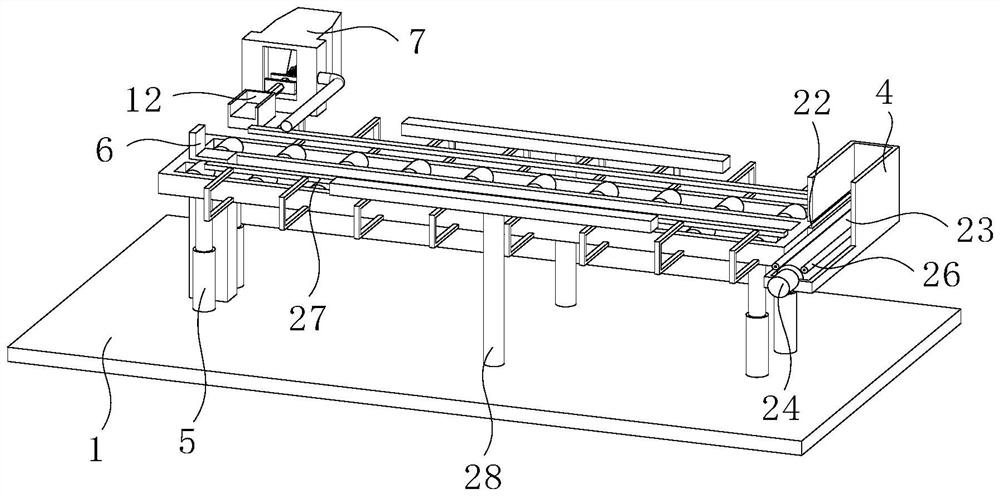

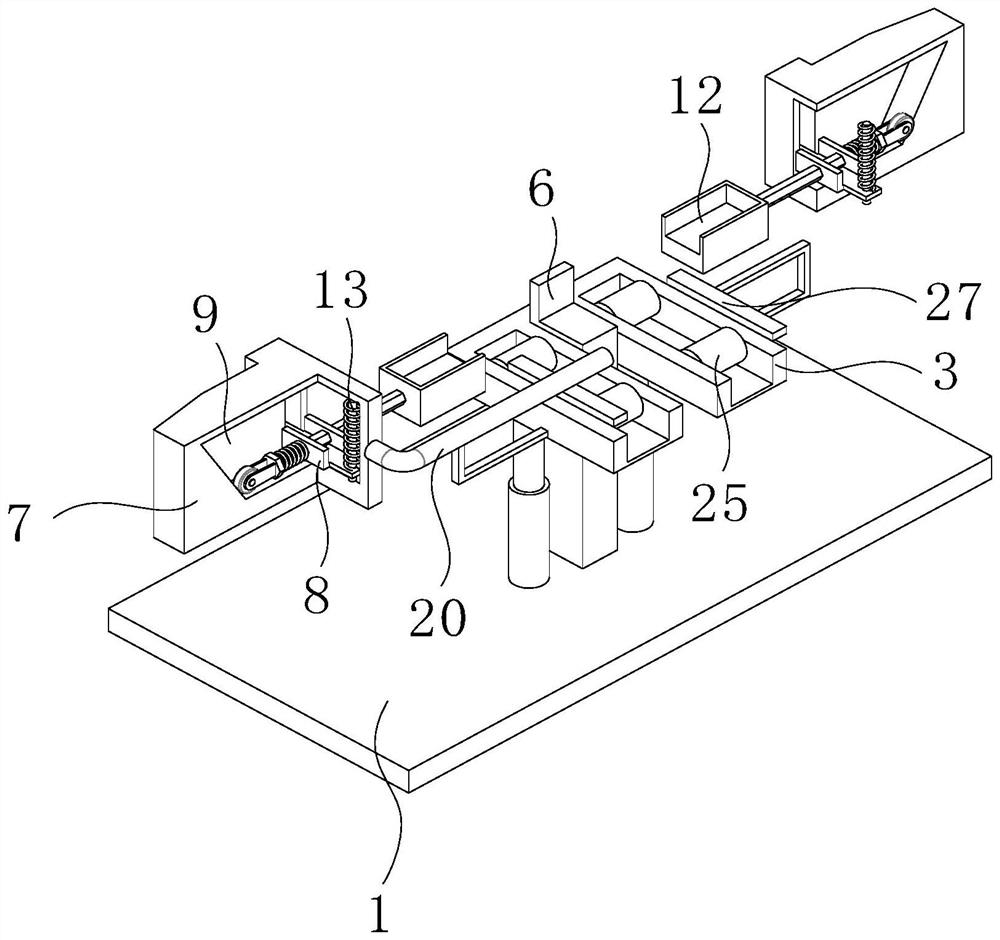

[0024] Such as Figure 1-5 As shown, a special circuit board bending resistance testing machine includes a support table 1 and an upper frame 2, the lower end of the upper frame 2 is fixedly connected to the upper surface of the support table 1, and a material table 3 is arranged between the upper frame 2 and the support table 1 , the right side of the material platform 3 is fixedly connected with the lower material box 4, and the bottom surface of the material platform 3 is fixedly connected with four supporting telescopic rods 5, and the lower end of the supporting telescopic rods 5 is fixedly connected with the upper surface of the supporting platform 1, and the material platform 3 The upper surface of the left end slides through a support column 6, and the lower end of the support column 6 is fixedly connected with the upper surface of the support platform 1.

[0025] The left end front and rear sides of material table 3 are all provided with movable box 7, and the inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com