Magnetic suspension compressor

A compressor and magnetic levitation technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of axial sensor detection data data errors, affecting system control accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

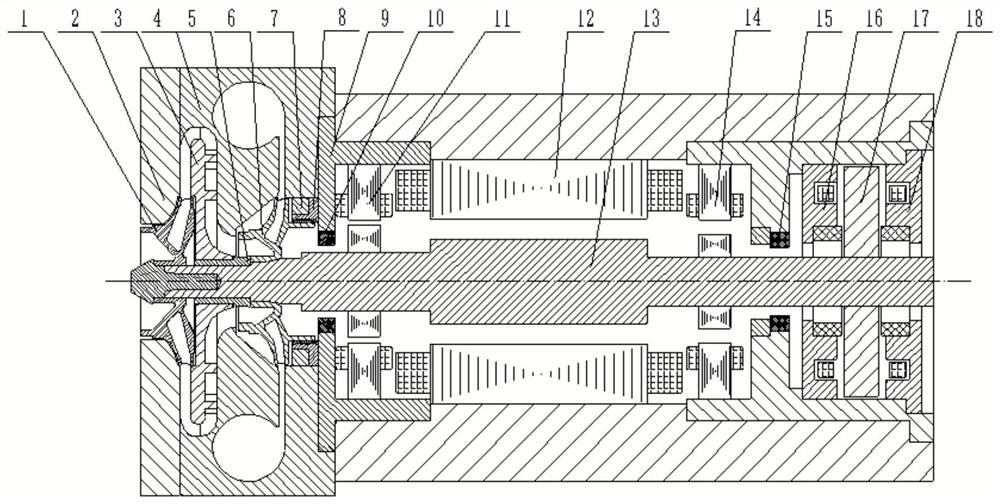

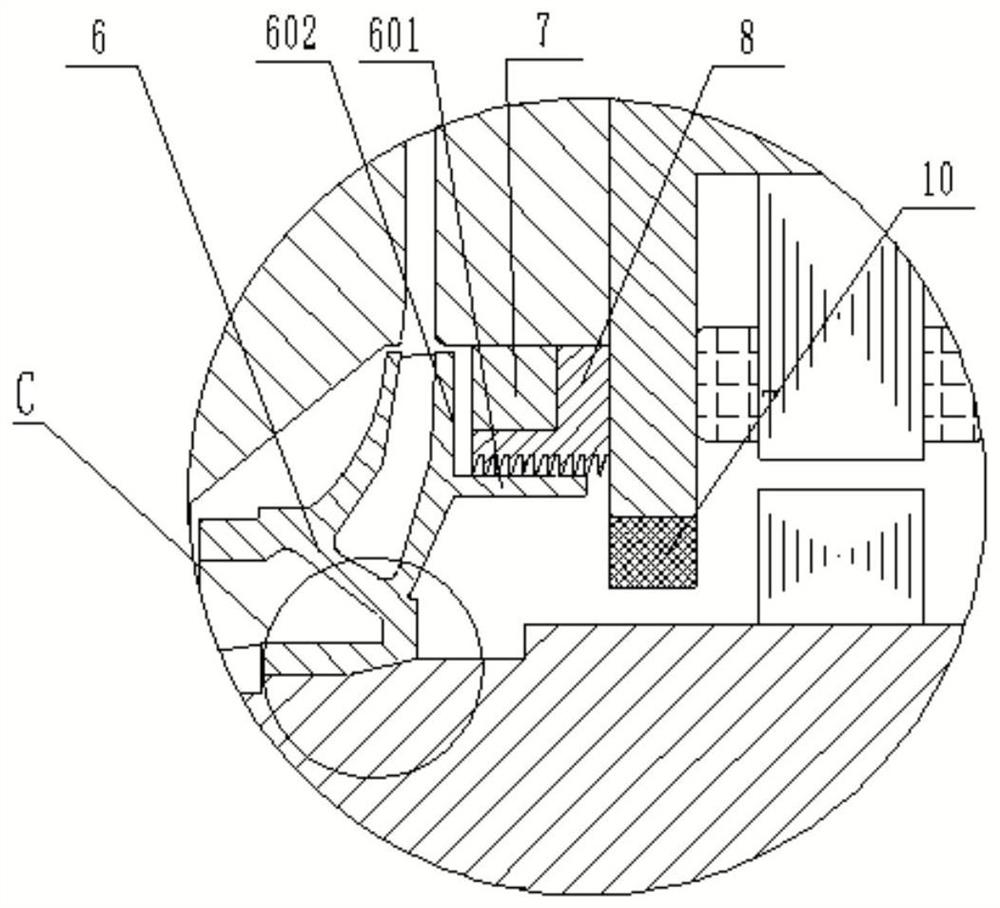

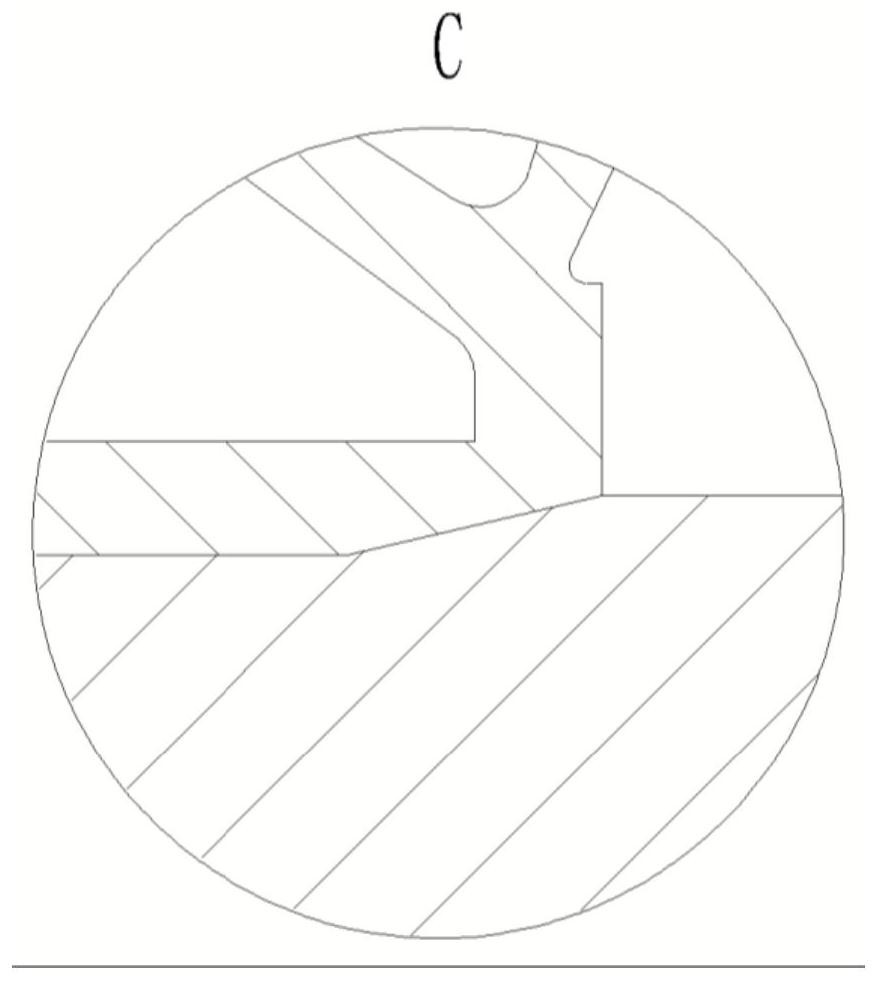

[0025] see in conjunction Figure 1 to Figure 5 As shown, according to the embodiment of the present application, the maglev compressor includes a motor main shaft 13, a first impeller 6, a reflux device 4, an axial displacement sensor 7 and a housing 9, the motor main shaft 13 is installed in the housing 9, and the reflux device 4 It is fixedly connected with the casing 9, the first impeller 6 is installed in the reflux device 4, and is sleeved outside the motor main shaft 13, the axial displacement sensor 7 is fixedly arranged relative to the casing 9, and the first impeller 6 is axially displaced One side of the sensor 7 has an axial detection surface 602 , and the axial displacement sensor 7 can detect the axial displacement of the first impeller 6 through the axial detection surface 602 .

[0026] The axial displacement sensor 7 of the magnetic levitation compressor is distributed on the back side of the first impeller 6, and directly detects the axial displacement of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com