Roller gap self-learning deviation correcting method and device

A self-learning, roll gap technology, applied in the field of steel rolling, can solve problems such as the inability to effectively improve the roll gap setting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

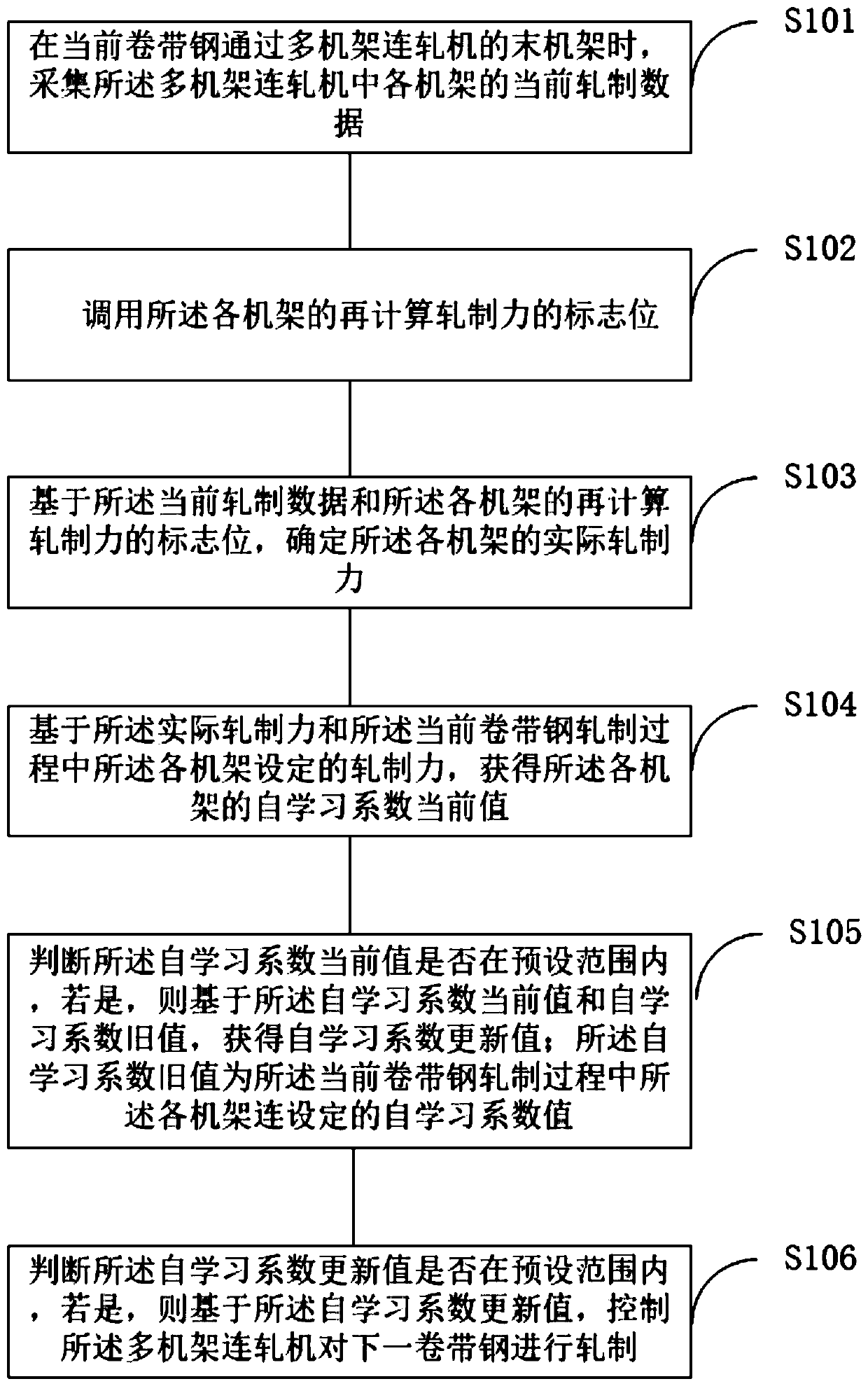

[0051] In this embodiment, a roll gap self-learning correction method is applied to a multi-stand continuous rolling process, and the method includes:

[0052] S101. When the current strip passes through the last stand of the multi-stand continuous rolling mill, collect the current rolling data of each stand in the multi-stand continuous rolling mill;

[0053] S102, calling the flags of the recalculated rolling force of each stand;

[0054] S103. Determine the actual rolling force of each stand based on the current rolling data and the flag bits of the recalculated rolling force of each stand; the actual rolling force is the recalculated rolling force or Measured rolling force;

[0055] S104. Obtain the current value of the self-learning coefficient of each stand based on the actual rolling force and the rolling force set by each stand during the current strip rolling process;

[0056] S105. Determine whether the current value of the self-learning coefficient is within a pre...

Embodiment 2

[0102] In this embodiment, a roll gap self-learning correction device is applied to the multi-stand continuous rolling process, see Figure 4 ,include:

[0103] The data acquisition module is used to collect the current rolling data of each stand in the multi-stand continuous rolling mill when the current strip passes through the last stand of the multi-stand continuous rolling mill;

[0104] A flag calling module, used to call the flag bits of the recalculated rolling force of each stand;

[0105] The first obtaining module is used to obtain the actual rolling force of each stand based on the current rolling data and the recalculated rolling force flag of each stand; the actual rolling force is recalculated Calculate rolling force or measured rolling force;

[0106] The second obtaining module is used to obtain the current value of the self-learning coefficient of each stand based on the actual rolling force and the rolling force set by each stand during the current strip r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com