Automatic filling system for gas well defoamer

A technology for automatic filling and defoaming, which is applied in wellbore/well components, production fluids, earth-moving drilling, etc. The effect of saving anti-foaming agents and improving the anti-foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

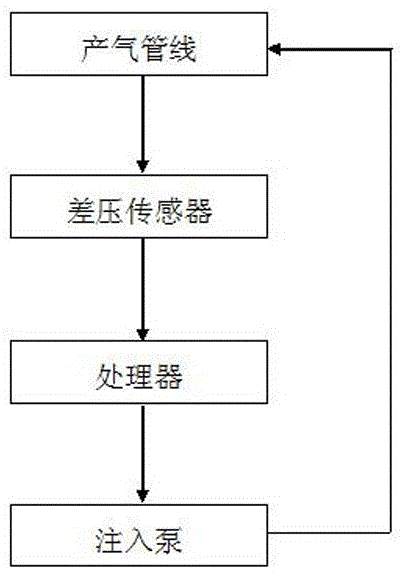

[0012] according to figure 1 As shown, the present invention is a set of gas well defoamer automatic filling system, the automatic filling system includes a differential pressure sensor, a processor and an injection pump. The differential pressure sensor is used to detect the liquid flow pressure in the gas production pipeline in real time, and transmit the detected pressure signal to the processor in time; the processor is used to judge and process the real-time signal from the differential pressure sensor, and the processor is preset with The trigger value of the liquid flow pressure (this value is obtained by using the monitoring software to collect the differential pressure change rate obtained by the intelligent controller in advance, and finds the differential pressure change value under the normal gas production and water outlet conditions); according to the trigger value, the injection pump is controlled. Start and stop; the injection pump communicates with the defoame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com