Oil well liquid level measuring method and device

A technology of liquid level measurement and measurement method, which can be used in construction and other directions, can solve problems such as measurement errors, and achieve the effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

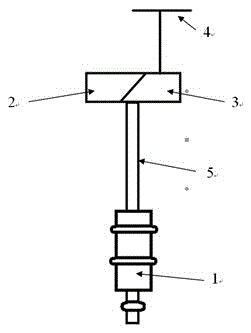

[0018] see figure 1 , The measurement method of the present invention uses the following device: the power supply 4 is connected with the submersible screw pump 1 by the cable 5 through the torque tester 2 and the frequency converter 3 . Wherein, the torque tester 2 and the frequency converter 3 can be combined together in the electrical equipment. The submersible screw pump 1 is installed underground in the oil well.

[0019] A method for measuring oil well liquid level of the present invention is obtained by calculation, and its steps are as follows,

[0020] a. Ground inverter 3 output frequency f 1 , calculate the speed n of the submersible screw pump 1, and substitute n into the formula (j), and calculate the torque T of the submersible screw pump 1 3 (f 1 );

[0021] T 3 =91.3δ 0 -n 0.45 +46.5(j)

[0022] In the formula, δ 0 is a constant

[0023] b. The ground torque tester 2 measures the total power output torque T 1 (f 1 );

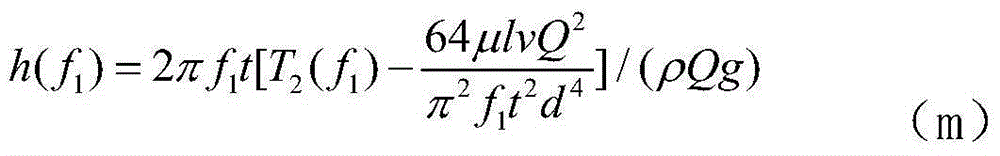

[0024] c. Calculate the torq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com