An Adjustable and Balanced Bilateral Drive Axial Piston Motor

A technology of axial piston motor and double-sided drive, which is applied in the field of axial piston motor, can solve the problems of different driving torques on both sides, different driving torques, and complicated design process, so as to improve working stability and improve Stability and the effect of reducing design difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

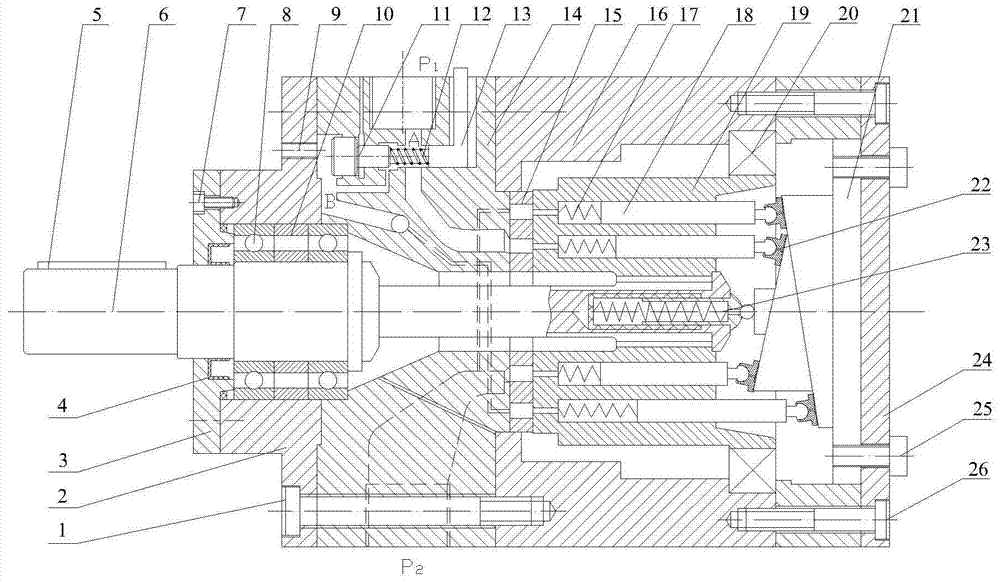

[0025] Example 1 see figure 1 , taking double-row plunger drive as an example, the adjustable balance bilateral drive axial plunger motor mainly includes: proportional valve core 11, return spring 12, adjustment handle 13, external threaded port and plug 9, ordinary double-sided shaft to the plunger motor. When the high-pressure oil is supplied to the plunger cavity in two ways from the oil inlet P1: a part of the high-pressure oil passes through the A oil port and the oil distribution plate 15, and directly supplies liquid to the inner row of the plunger cavity to generate driving force and The driving torque drives it to rotate on one side of the cylinder block 19; the other part of the high-pressure oil is depressurized by the proportional valve core 11, and then supplies liquid to the outer discharge plunger chamber through the B oil port and the oil distribution plate 15, resulting in the same The driving force and driving moment in the same direction in the row drive th...

Embodiment 2

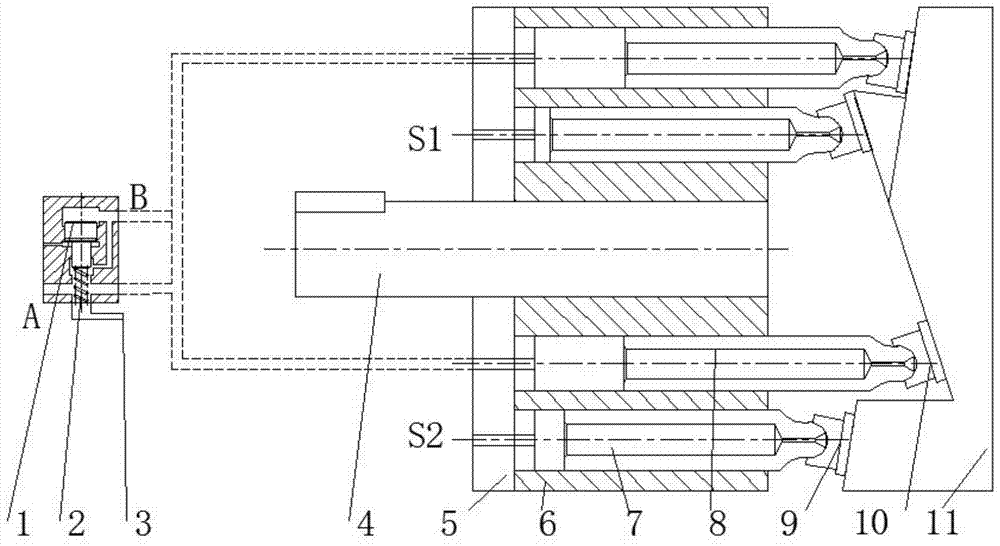

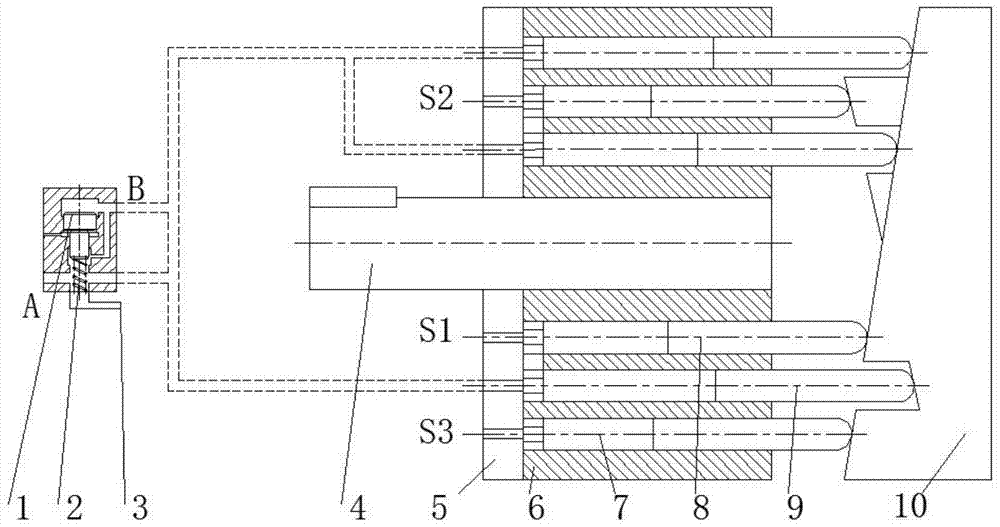

[0030] Embodiment 2 see image 3 , 4 Schematic diagrams of two different regulation of an adjustable balanced double-sided drive axial piston motor with three rows of plungers.

[0031] see image 3 , the oil at oil port A supplies liquid to the middle row of plunger chambers S2, and the oil at oil port B supplies liquid to the inner row of plunger chambers S1 and outer row of plunger chambers S3. The actual size of the middle row of plunger chambers is larger than that of the inner and outer row of plunger chambers. After pressure regulation, the torque at the middle row of plungers can be guaranteed to be the same as that at the inner and outer row of plungers. The sum is balanced so that the cylinder is completely floating. When the pressure in the plunger chamber fluctuates and the torque of the cylinder body 6 is unbalanced, the return spring 2 is adjusted by the adjustment handle 3 to restore the cylinder body 6 to a balanced state.

[0032] Figure 4 , the oil at o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com