Plunger pump with energy recycling function

A technology of energy recovery and plunger pumps, which is applied to parts, pump elements, mechanical equipment, etc. of elastic fluid pumping devices, and can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

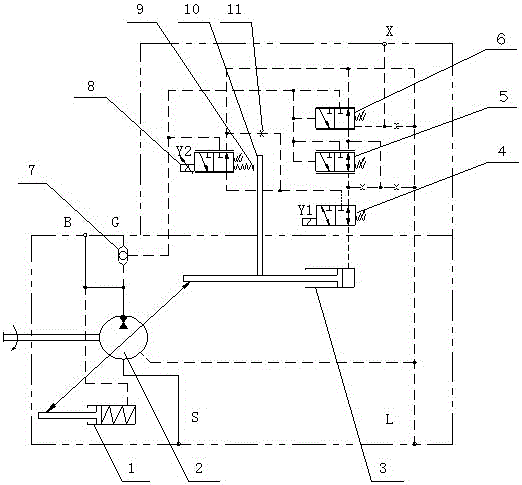

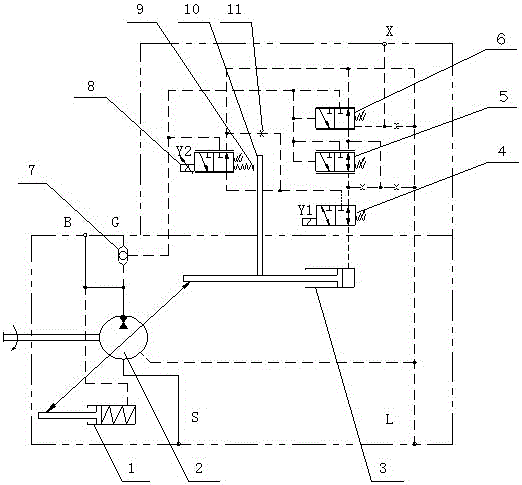

Image

Examples

Embodiment approach

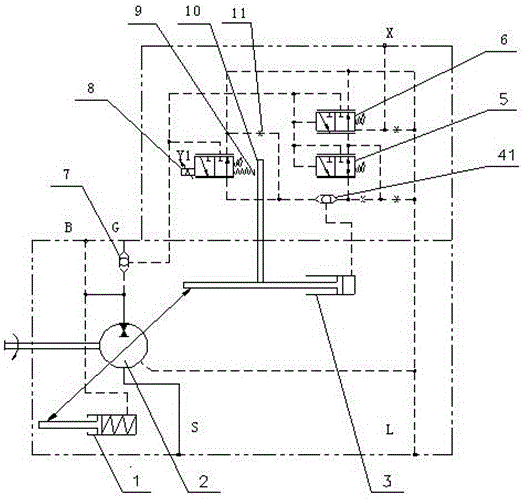

[0051] There is another embodiment, the difference from Embodiment 2 is that the two-position three-way solenoid valve YI is replaced by the second shuttle valve 41, such as image 3 As shown, the oil port of the second shuttle valve 41 is connected to the variable cylinder 3, the oil ports at the other two ends are respectively connected to the oil port 3 of the pressure cut-off valve 5 and the oil port 3 of the electric proportional valve YⅡ8, and the oil port 2 of the pressure cut-off valve 5 is connected to The oil port 3 of the load-sensitive flow control valve 6 and the second shuttle valve can select two control oil circuits of the pump and the motor to ensure that the two control methods do not interfere with each other.

[0052] 1) Working condition of load sensitive variable pump:

[0053] That is, the initial working condition (the two-position three-way solenoid valve YⅠ and the electro-proportional valve YⅡ are not energized), and the difference between the pump o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com