Oil distribution structure with automatic gap compensation function

A technology of oil distribution and clearance, which is applied in the direction of fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc., can solve the problems affecting the performance of drilling rigs, the reduction of working hydraulic oil flow, and the reduction of output efficiency, etc., and achieve structural Simple, time-saving, and easy-to-process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

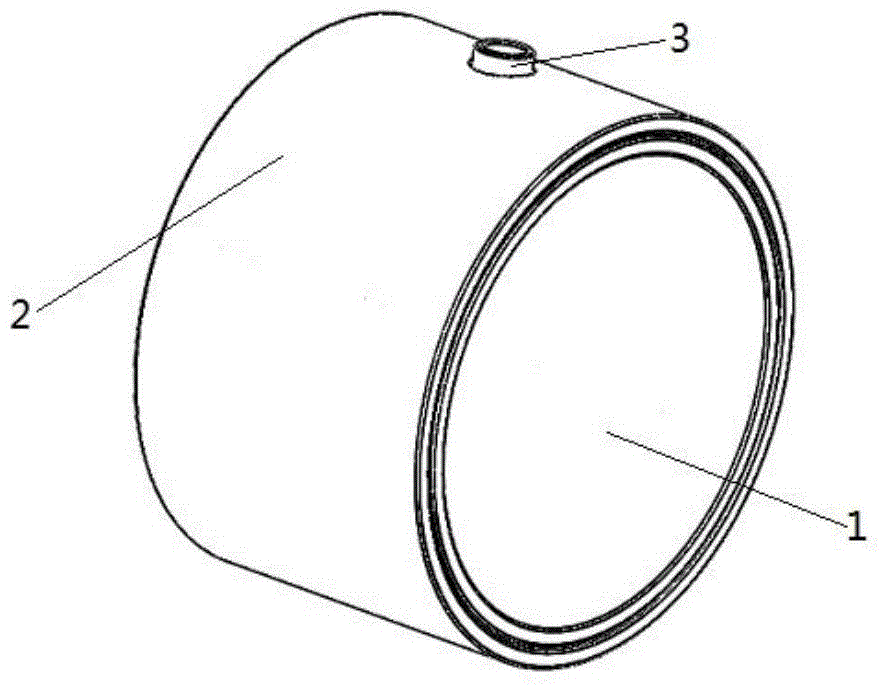

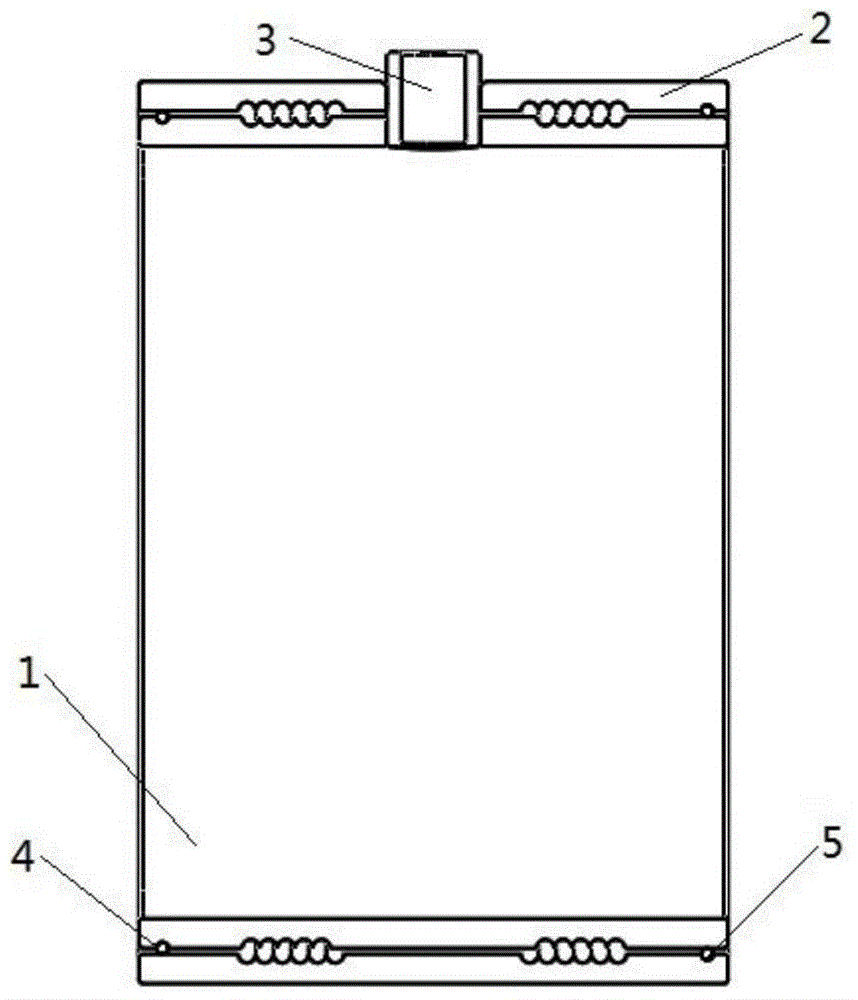

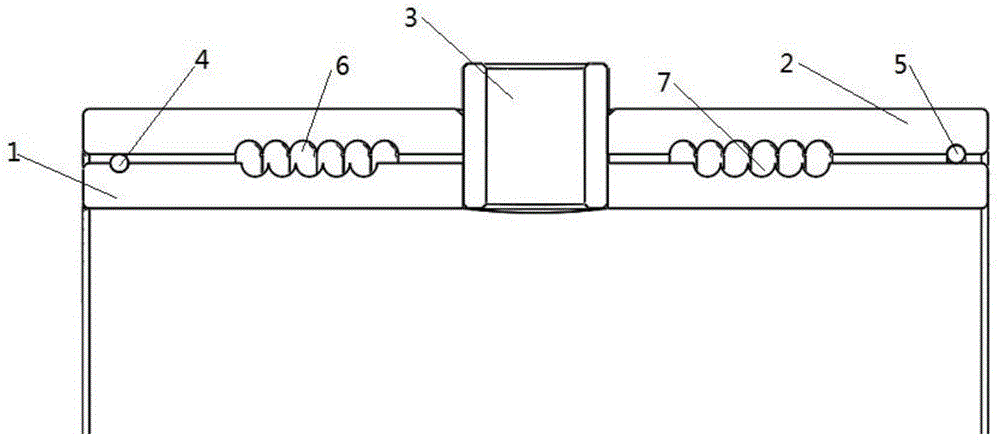

[0032] see Figure 1 to Figure 7 , showing the oil distribution structure with automatic clearance compensation of the present invention.

[0033] The oil distribution structure with automatic clearance compensation includes an oil distribution inner sleeve 1 and an oil distribution outer sleeve 2. The oil distribution inner sleeve 1 is cylindrical and can be sleeved on the main shaft of the drilling rig, and the oil distribution sleeve 2 is sleeved on the rig main shaft. The outer edge of the oil distribution inner sleeve 1.

[0034] In order to provide the entry of oil distribution, an oil inlet core pipe 3 is provided, and the oil inlet core pipe 3 is passed through the oil distribution inner sleeve 1 and the oil distribution outer sleeve 2 and can provide the entry of oil. The oil distribution inner sleeve 1 and the oil distribution inner sleeve 1 and The oil distribution jacket 2 is respectively provided with an inner jacket piercing hole 8 and an outer jacket piercing h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com