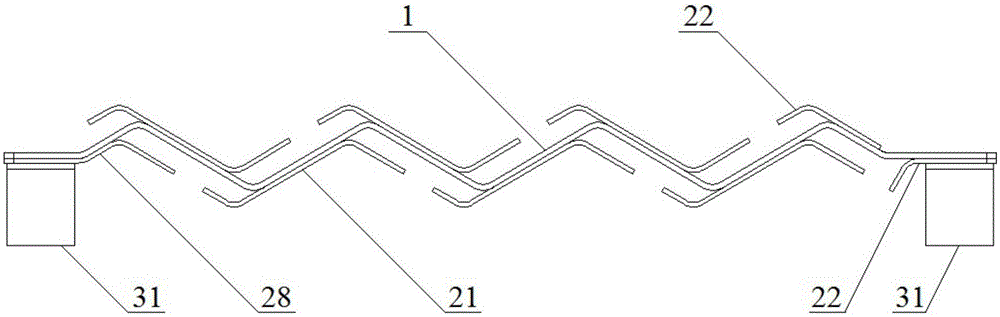

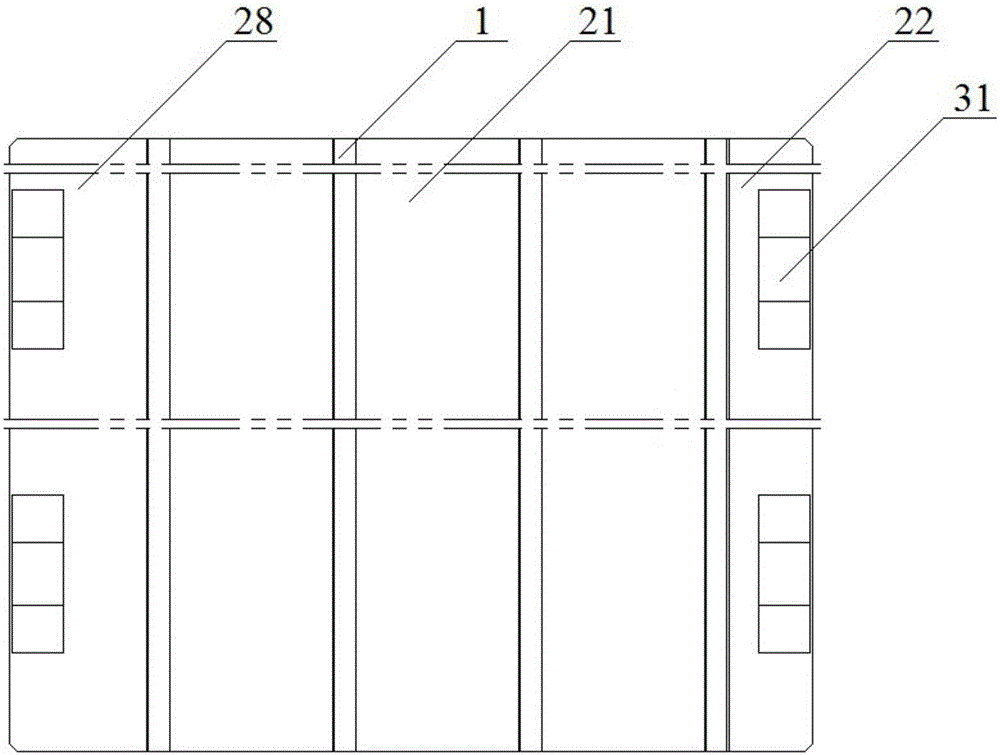

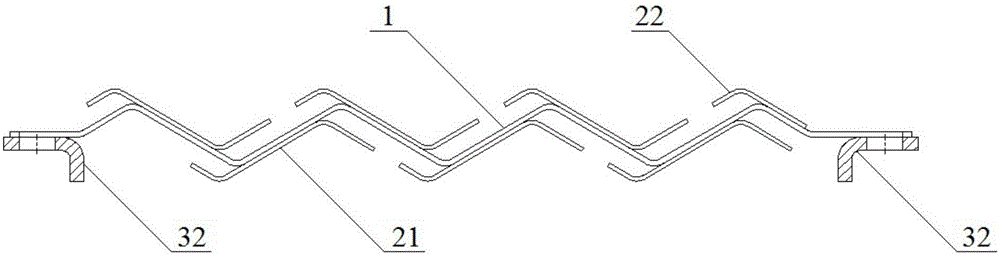

Corrugated plate assembly for dryer of ACP1000 nuclear power vapor generator

A steam generator and corrugated plate technology, which is applied in the field of nuclear power, can solve the problems that the drying capacity of the steam generator dryer and the operation effect need to be improved, and the manufacturing level is limited, so as to achieve the effects of improving dehumidification capacity, low flow resistance, and preventing displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described in detail with the accompanying drawings and preferred embodiments below. Through these descriptions, the features and advantages of the present invention will become more apparent.

[0073] The "transverse" in the present invention refers to the extension direction of the corrugation on the substrate, and the "longitudinal" refers to the direction perpendicular to the horizontal direction on the plane where the substrate is located; the "front" of the substrate is the surface of the substrate where the tail hook is located, and the "longitudinal" of the substrate is The "reverse side" is the substrate surface opposite to the surface where the tail hook is located; the "front end" of the substrate is the shorter end of the straight section on the substrate, and the "rear end" of the substrate is the longer end of the straight section on the substrate; The "inner surface" of the water retaining member and the supporting mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com