Regulation system and method for preventing fire extinguishing caused by sudden increase in pressure of cold ash hopper of coal-fired boiler

A technology for coal-fired boilers and regulating systems, which is applied to steam boiler components, steam boilers, steam boiler accessories, etc., to prevent the sudden increase in pressure of the cold ash hopper, improve the adjustment ability, and avoid fire-fighting accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in detail below in conjunction with accompanying drawing:

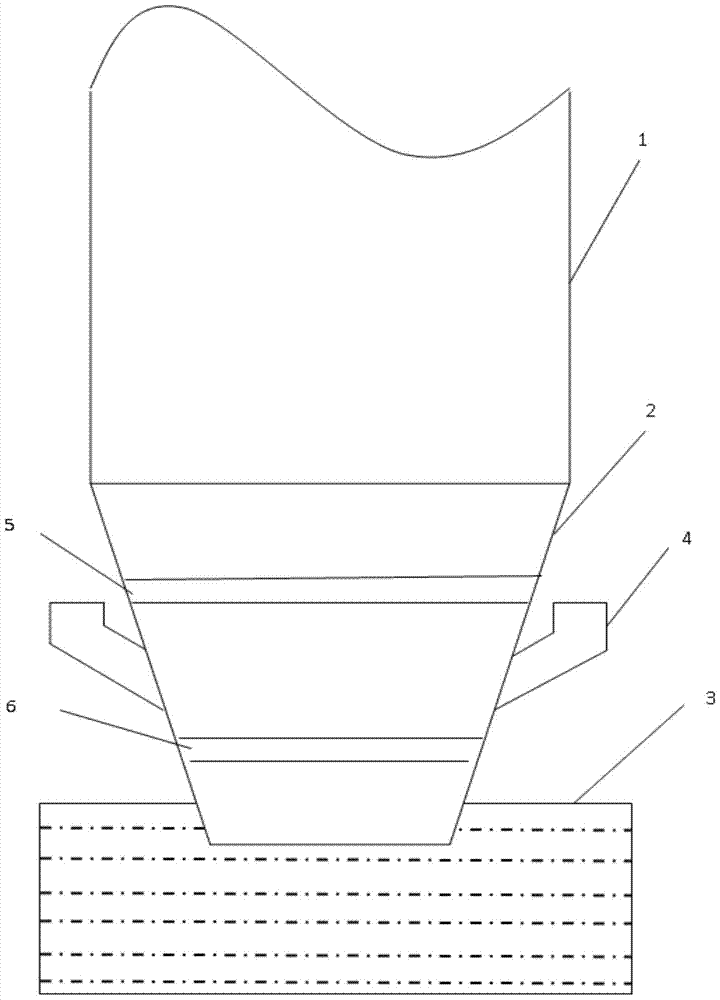

[0034] like figure 1 As shown, the cold ash hopper 2 area below the boiler body 1 and above the water seal tank 3 is divided into three parts along the height direction, and the upper dilution bellows 5 and the pressure relief safety are respectively arranged at the middle height of each part from top to bottom. Valve 4 and lower dilution bellows 6. Two layers of dilution bellows are arranged in the cold ash hopper 2 area, and the upper dilution bellows 5 and the lower dilution bellows 6 cover the surroundings of the cold ash hopper 2, which greatly reduces the dilution dead angle.

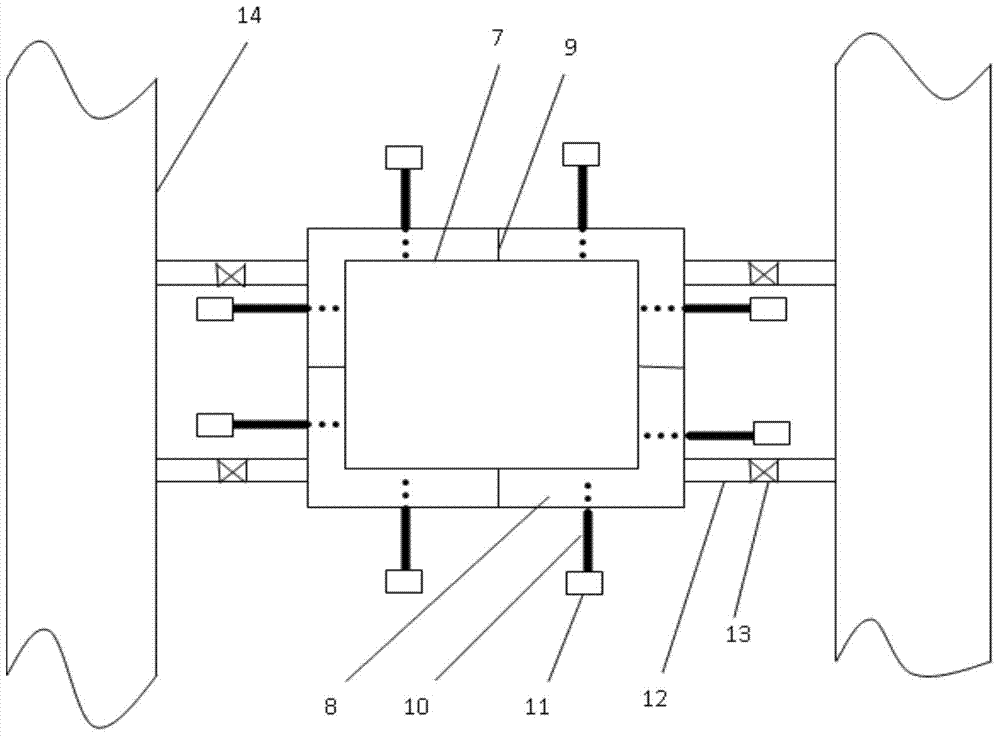

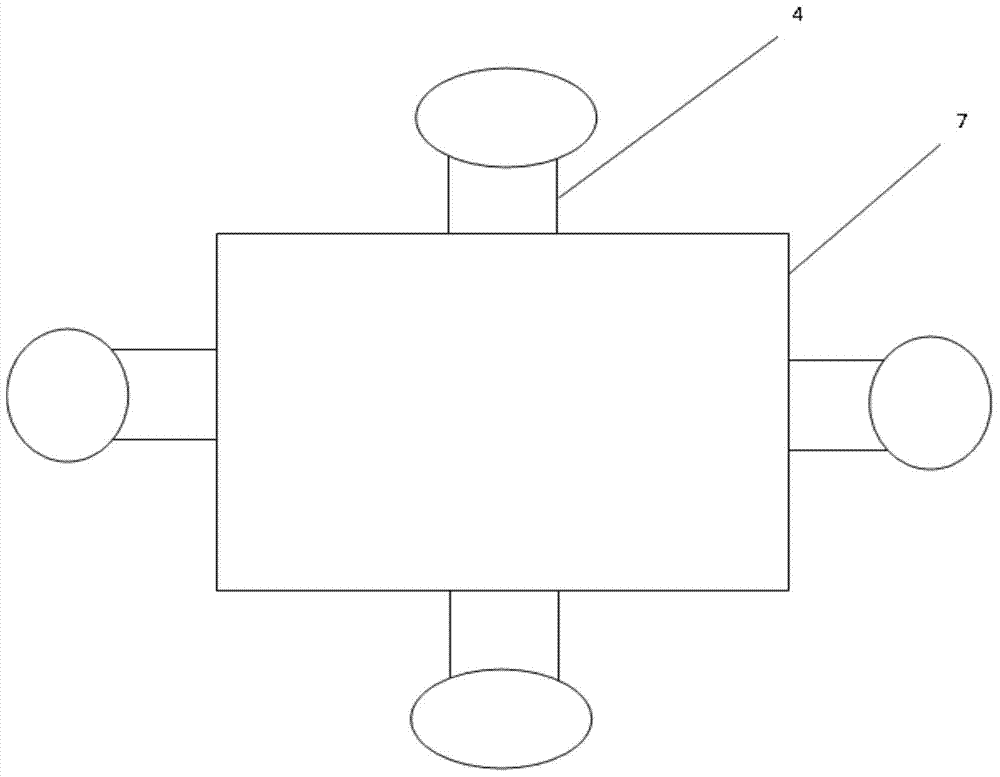

[0035] like figure 2 As shown, both the upper dilution air box 5 and the lower dilution air box 6 are connected to the secondary air box 14 through the air box communication pipe 12 . The upper dilution air box 5 and the lower dilution air box 6 are divided into four dilution air boxes 8 by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com