Ground lead current signal monitoring sensor for end screen of transformer bushing

A technology of transformer bushing and monitoring sensor, applied in the direction of measuring current/voltage, instrument, measuring electricity, etc., can solve the problems of insufficient ground wire frequency band, current signal measurement error, signal distortion, etc., to prevent water ingress and grounding Reliable, easy-to-install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

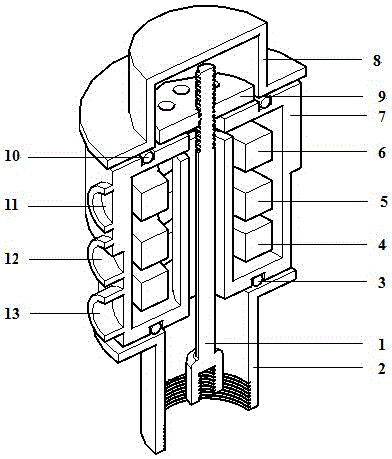

[0020] to combine figure 1 The present invention is further described.

[0021] Such as figure 1 As shown in Fig. 1 , a current signal monitoring sensor for the grounding wire at the end screen of a transformer bushing has a coaxial cylindrical structure as a whole. The current enters the conductive rod 1 from the lead-out line of the end screen of the bushing, flows into the shell 7 and the fixed base 2 of the sensor through the conductive disc 9, and finally flows into the grounding part of the lead-out line interface of the end screen of the transformer bushing along the base 2, so that the conductive rod and the conductive circle The loop formed by the disk 9, the casing 7 and the base 2 has a frequency band up to 100MHz, which is convenient for measuring partial discharge signals in a wide frequency range of 20KHz-40MHz. Coil 4, coil 5 and coil 6 are all ring-shaped, and are sleeved on the conductive rod 1 side by side, and are inside the shell 7, so the conductive rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com