A pinhole optical lens

An optical lens and pinhole technology, applied in the field of optical lens, can solve the problems of unfavorable filter installation and focusing, large light aperture, heavy overall weight, etc., achieve good image quality, ensure picture brightness, and overcome lens focus drift A large amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

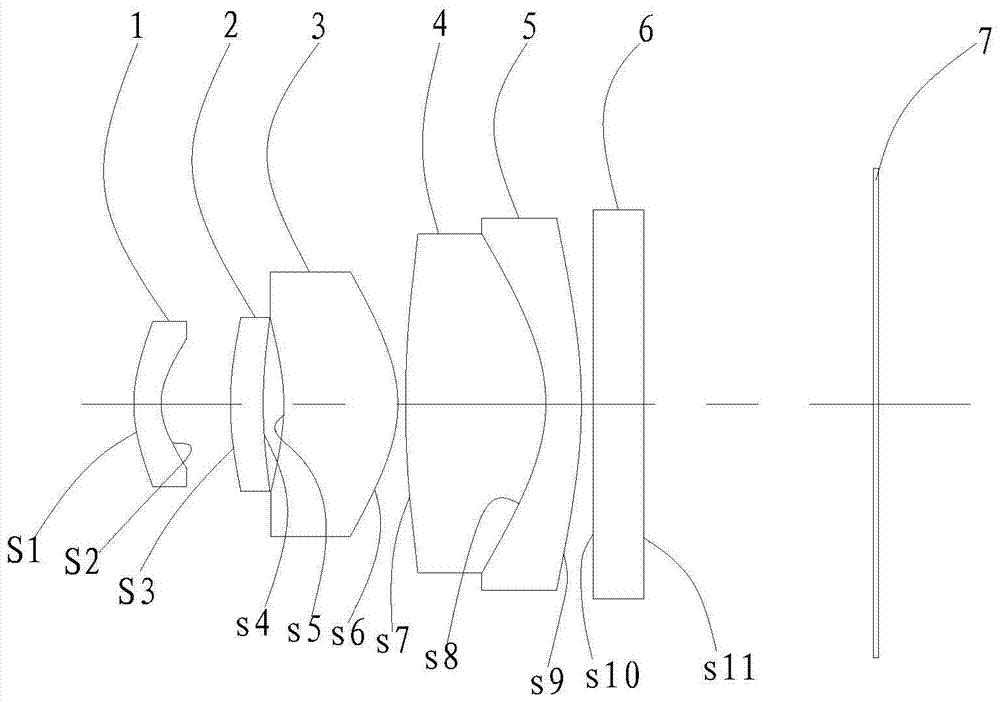

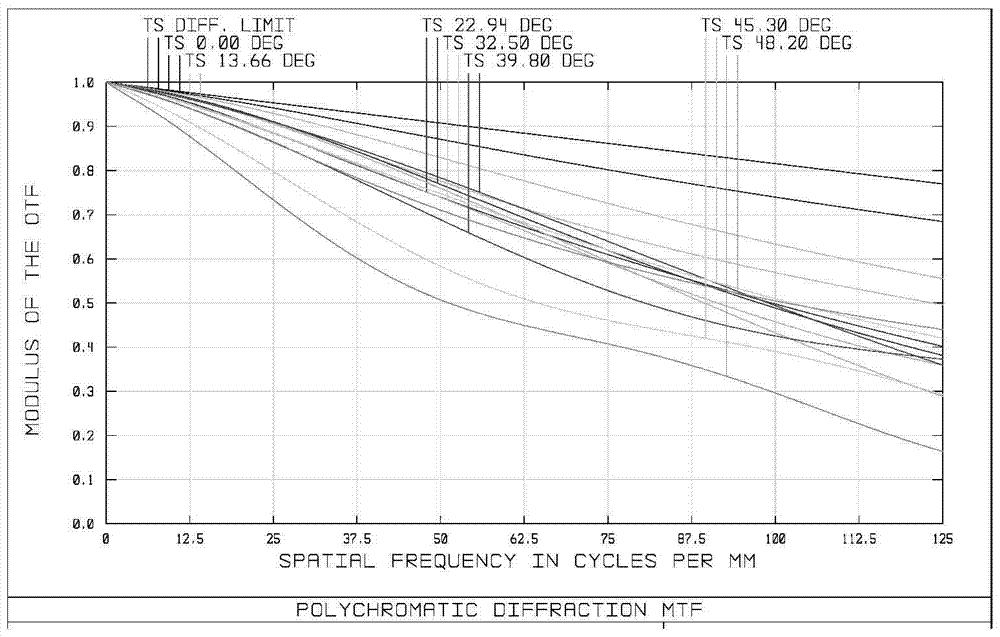

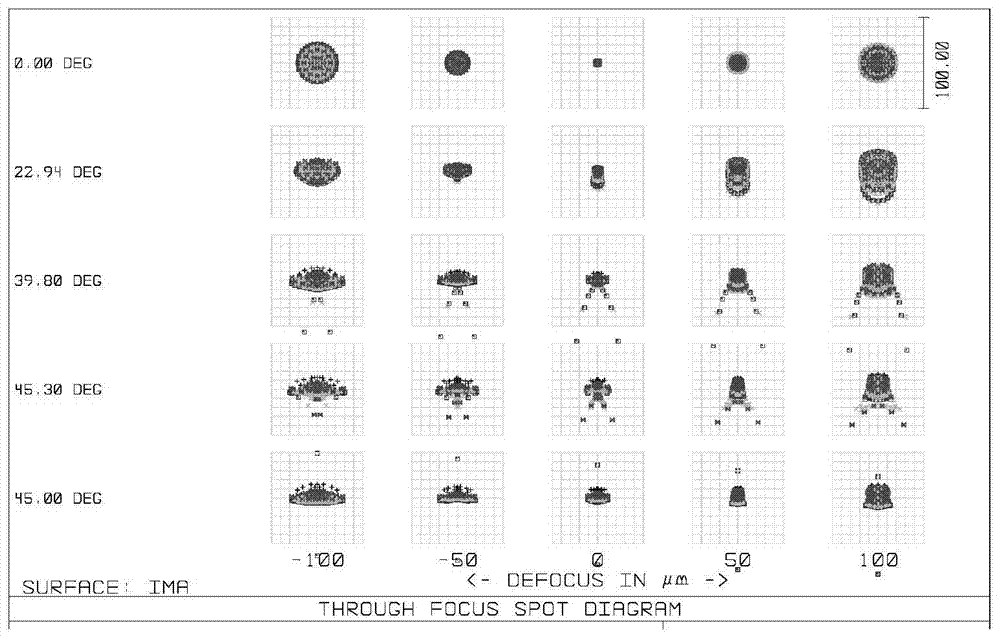

[0049] Such as Figure 2 to Figure 5 As shown, f=4.3mm, F#=2.5, FOV=110°, BFL=5.6942, TTL=12.278, the focal length of each lens is shown in the table below:

[0050] f1

f2

f3

f4

f5

f2 / f1

f3 / f1

f4 / f5

BFL / TTL

-5.8197

15.3051

9.3

3.38

-6.027

-2.6299

-1.598

-0.5608

0.4637

[0051] Each lens surface, R value, thickness and material thereof in the first embodiment are as follows:

[0052]

[0053] Each lens surface parameter in the first embodiment is as follows:

[0054]

Embodiment approach 2

[0056] Such as Figure 6 to Figure 9 As shown, f=4.3mm, F#=2.45, FOV=105°, BFL=5.3142, TTL=11.89, the focal length of each lens is shown in the table below:

[0057] f1

f2

f3

f4

f5

f2 / f1

f3 / f1

f4 / f5

BFL / TTL

-6.2873

15.713

9.6

3.33

-5.63

-2.4992

-1.5269

-0.5915

0.4469

[0058] Each lens surface, R value, thickness and material thereof in the second embodiment are as follows:

[0059]

[0060] Each lens surface parameter in the second embodiment is as follows:

[0061]

Embodiment approach 3

[0063] Such as Figure 10 to Figure 13 As shown, f=4.3mm, F#=2.4, FOV=96°, BFL=5.842, TTL=12.41, the focal length of each lens is shown in the table below:

[0064] f1

f2

f3

f4

f5

f2 / f1

f3 / f1

f4 / f5

BFL / TTL

-5.8

15.71

9.89

3.41

-6.34

-2.7086

-1.7052

-0.5379

0.47

[0065] In the third embodiment, each lens surface, R value, thickness and material thereof are as follows:

[0066]

[0067] The parameters of each lens surface in the third embodiment are as follows:

[0068]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com