Improved method for optimally designing noise of main parameter of bevel gear of transmission

An optimized design, helical gear technology, applied in the direction of instrumentation, calculation, electrical digital data processing, etc., can solve problems such as long time length, complex modeling, research, etc., and achieve the effect of fast calculation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

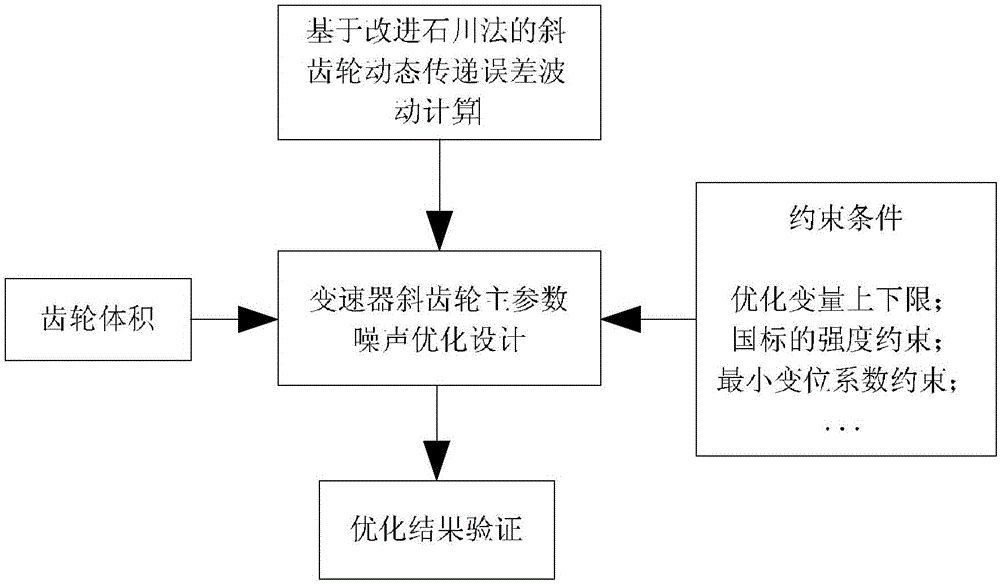

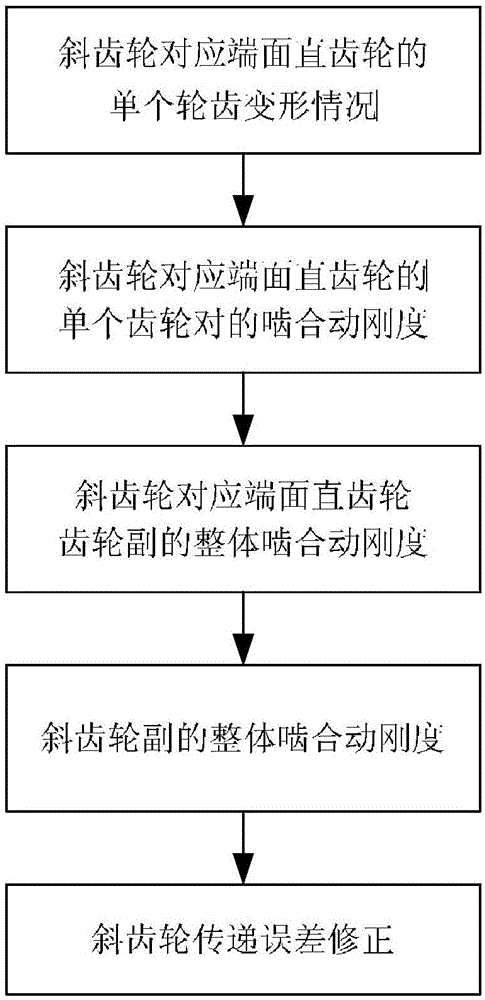

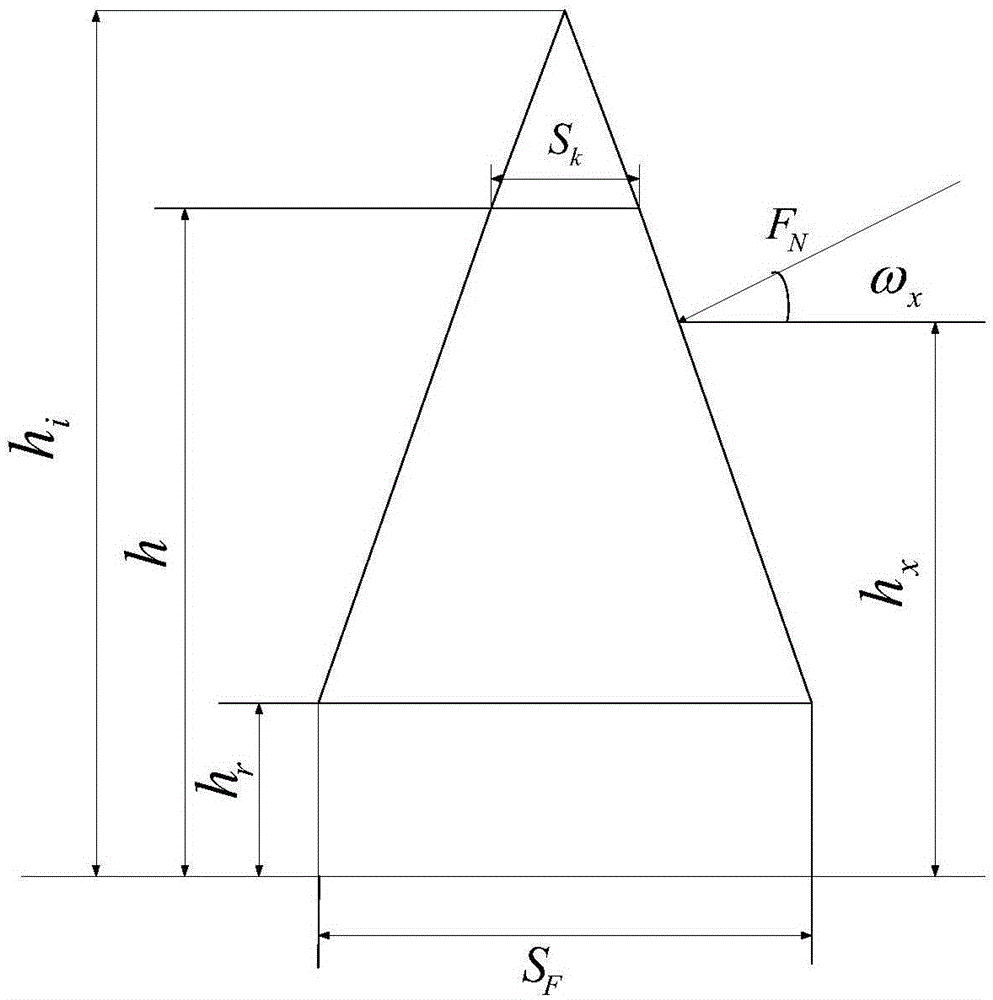

[0045] Based on the attached diagrams and embodiments, the process of the improved transmission oblique gear parameter noise optimization design described in the present invention is based on the present invention.

[0046] The overall flow chart of the improved transmission of the transmissions oblique gear of the transmission of the transmission is figure 1 The main steps are: First of all, based on improving Ishikawa Method, the calculation model of the dynamic transmission error and its fluctuation value of the oblique gear is established;One optimize the goal, considering the national standard's requirements for gear strength and other constraints, establish a genetic algorithm -based transmission diagonal gear main parameter parameter noise and design mathematical model to optimizeThe parameters are calculated in strength, noise, etc. to verify the optimization results.

[0047] As preferably, choose the four -gear oblique gear of the FAW hybrid passenger 5BB080 as an embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com