Automatic warehouse management system

An automated warehouse and management system technology, applied in the field of automated warehouse management systems, can solve problems such as high labor intensity, warehouse door opening, and cargo safety, and achieve the effects of improving automation, reducing labor intensity, and ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

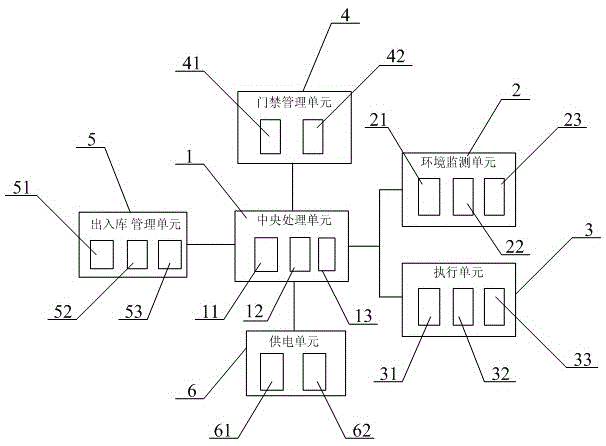

[0020] as attached figure 1 shown

[0021] The present invention provides an automated warehouse management system, which includes a central processing unit 1, an environment monitoring unit 2, an execution unit 3, an access control management unit 4, a storage management unit 5 and a power supply unit 6, and the central processing unit 1 is wired The environment monitoring unit 2, the execution unit 3, the access control management unit 4 and the power supply unit 6 are electrically connected in a manner to play the role of information data processing and control; the environment monitoring unit 2 is electrically connected to the central processing unit 1 in a wired manner , which plays the role of environmental monitoring; the execution unit 3 is electrically connected to the central processing unit 1 through a wired mode, and plays a role in improving the environment; the access control management unit 4 is bidirectionally connected to the central processing unit through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com