Image processing method for quickly and automatically detecting soldered dot unsatisfied products of electric connectors

An electrical connector and automatic detection technology, applied in the field of image processing, can solve problems such as automatic detection of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

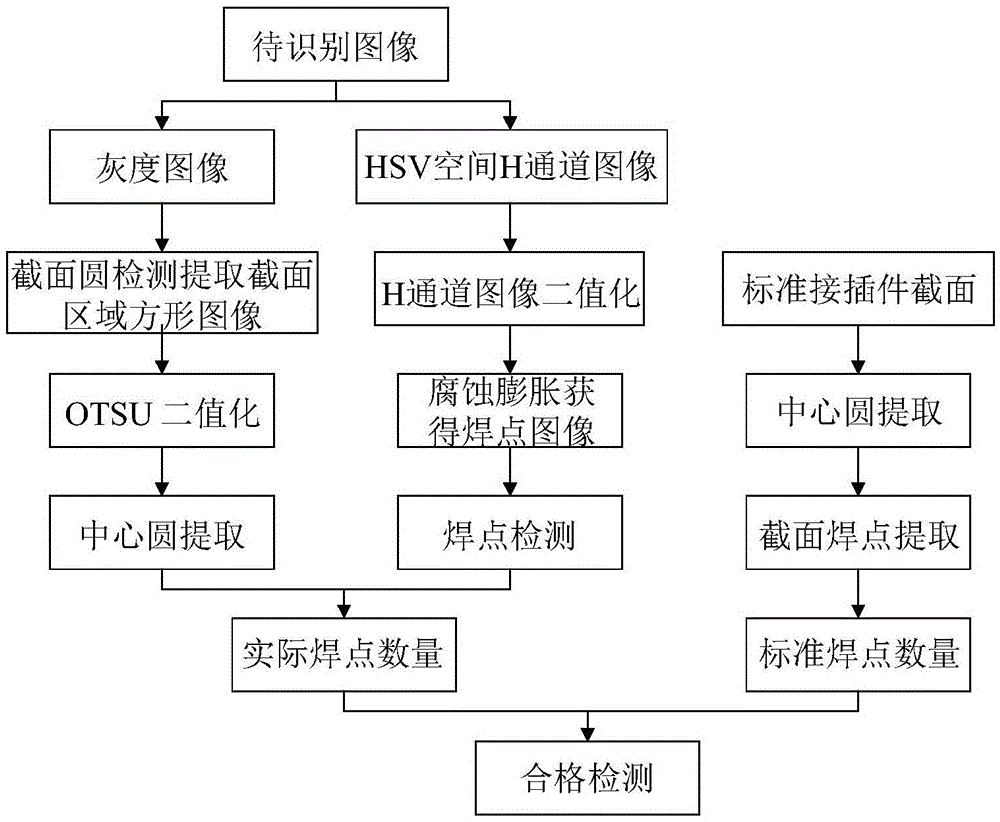

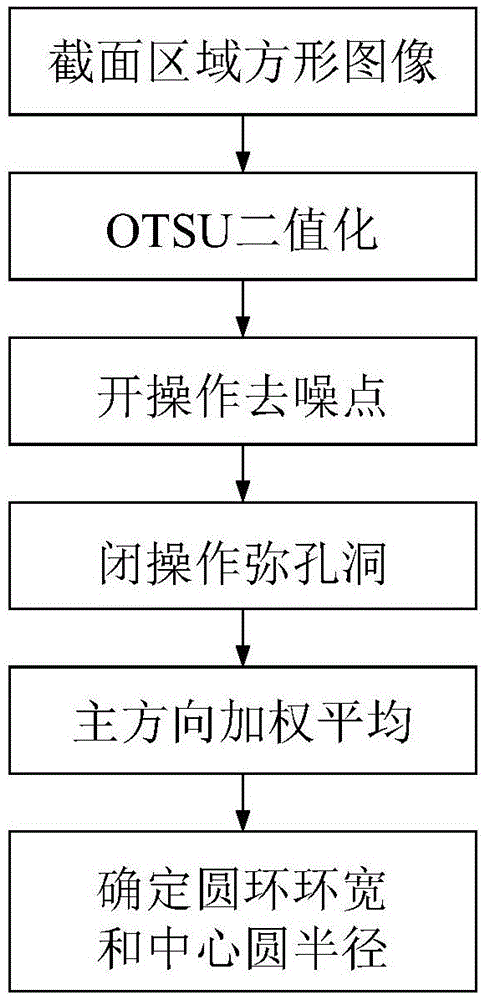

[0050] refer to Figure 1 to Figure 4 As shown, a kind of image processing method of fast automatic detection electrical connector solder joint unqualified product of the present invention, comprises:

[0051] First of all, the original image that needs to be inspected to detect whether the solder joint is qualified or not is collected by a camera that is not fixed relative to the section of the electrical connector and stored.

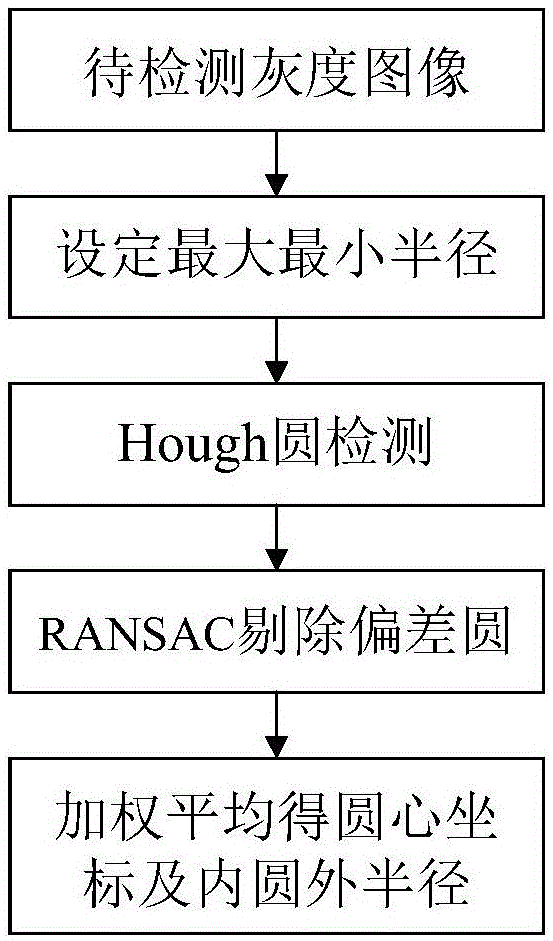

[0052] Next, extract the center of the section of the electrical connector and the outer radius of the inner circle. For details, refer to figure 2 As shown, set the maximum and minimum radii, and perform Hough circle detection on the grayscale image to extract mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com