Glass lamp tube processing technology

A processing technology, glass lamp technology, applied in the direction of lampshade, tube/lamp screen manufacturing, application of luminous paint, etc., can solve the problems of long time-consuming, glass lamp influence, low pass rate of finished products, etc., to eliminate The generation of defective products, saving the cost of production materials, and the effect of improving the production pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the present invention be further understood, the present invention will be further described below with reference to accompanying drawing and specific embodiment of description:

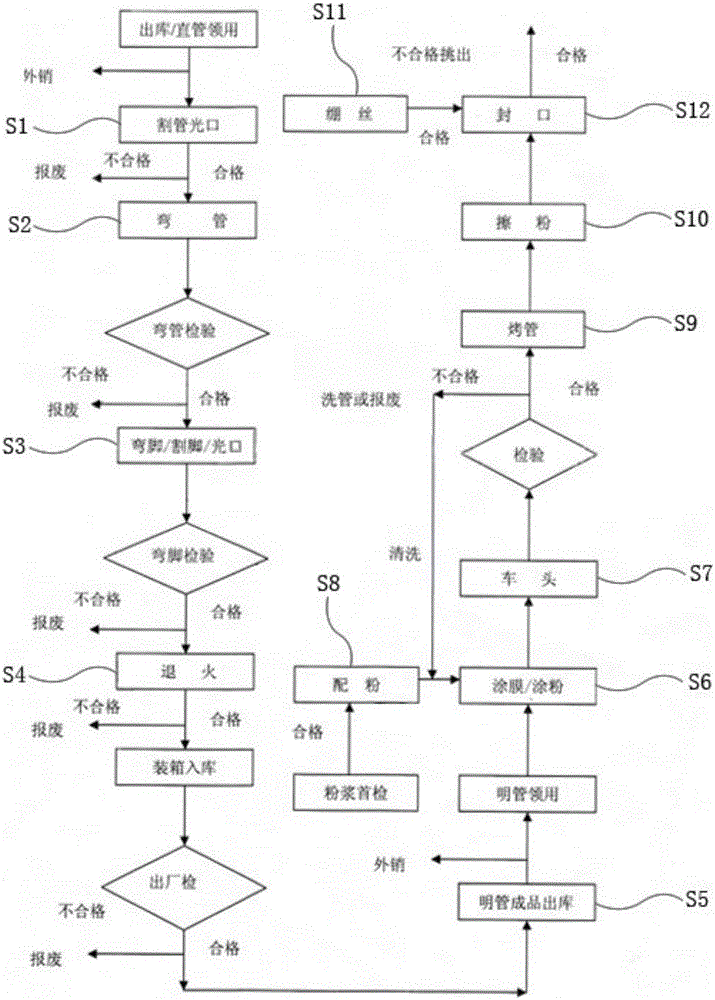

[0014] Such as figure 1 Shown, a kind of processing technology of glass lamp tube, comprises the following steps: cut tube light mouth, bend pipe, bend foot / cut foot / light mouth, anneal, open tube coating film powder, car head, bake pipe, rub powder and Sealing, there is a main inspection program behind the front of the car. In the main inspection program, the gloss meter and the thickness meter are respectively used to test the gloss and thickness of the coating powder inside the open tube behind the front of the car. The tested coating gloss If the thickness is not greater than 15 and the powder coating thickness is not greater than 5um, the test is qualified, and the unqualified exposed tubes are washed or scrapped. If it is within the repairable range, the tubes are cleane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com