Method for protecting anode of lithium sulfur battery

A technology of lithium-sulfur battery and sulfur battery, which is applied in the field of electrochemistry, achieves the effect of strong practicability, easy industrialization, and realization of industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

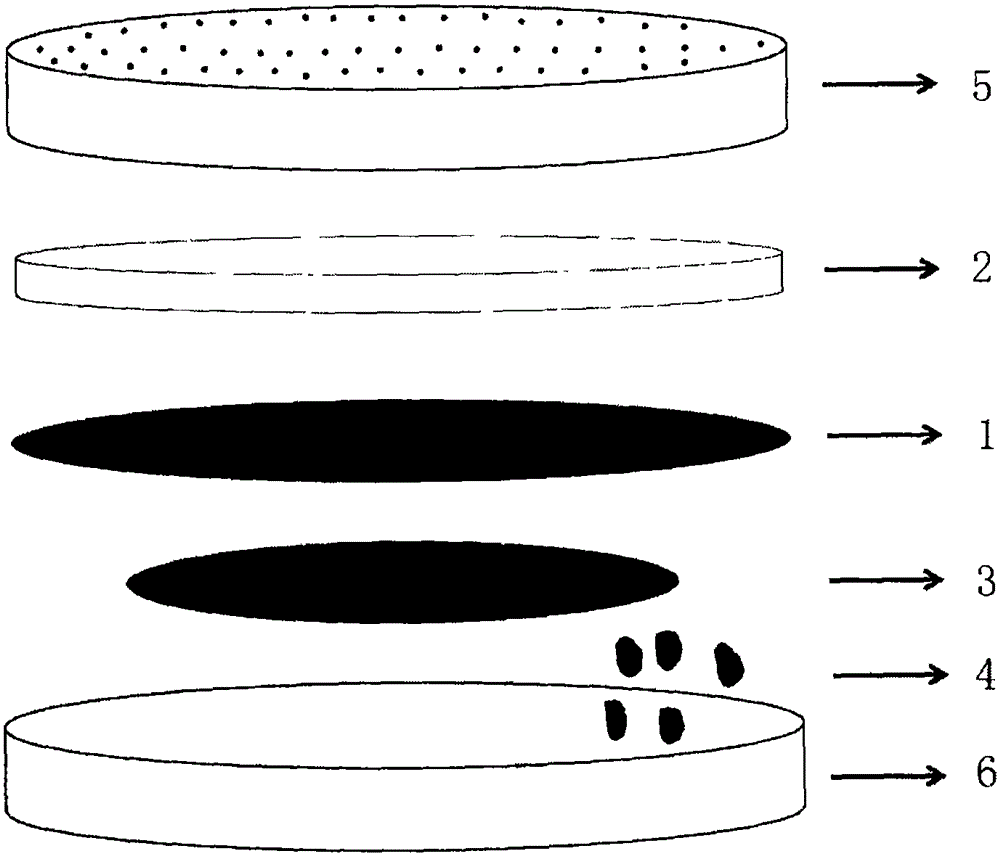

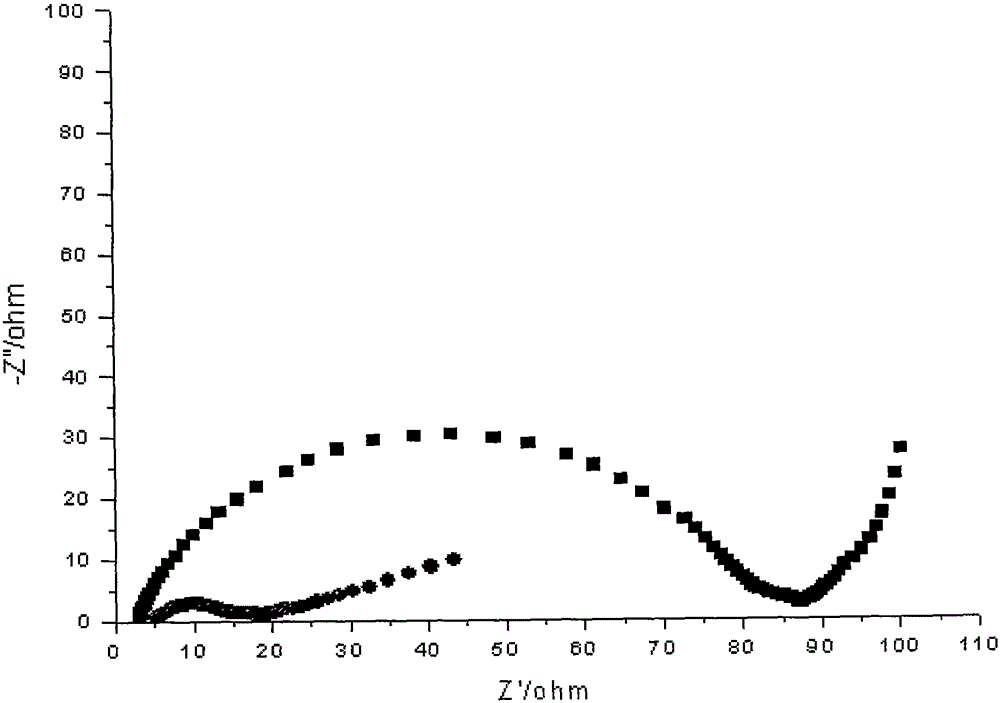

Embodiment 1

[0020] Weigh 0.32g activated carbon and 0.04gLiNO 3 , mix it in a mortar and grind it evenly, then pour it into a reaction bottle containing 0.04g of adhesive LA132 dispersed with 10g of dispersant, and stir at room temperature for 12h. After the slurry is evenly stirred, use a film applicator with a suitable thickness to coat evenly on one side of the diaphragm. Generally, after the coated diaphragm is naturally dried, it is placed in a vacuum oven at 60°C for 12 hours, and the baked diaphragm is cut. Form a disc with a diameter of Φ19mm, weigh and number it to prepare a separator with a functional protective coating, and then assemble a lithium-sulfur battery to test the relevant electrochemical performance. The lithium-sulfur battery is a CR2025 type button battery, and its positive electrode is a carbon / sulfur compound (90% sulfur content, LA132 is used as a binder), with metal lithium as the negative electrode, and the diaphragm is the functional protective coating prepar...

Embodiment 2

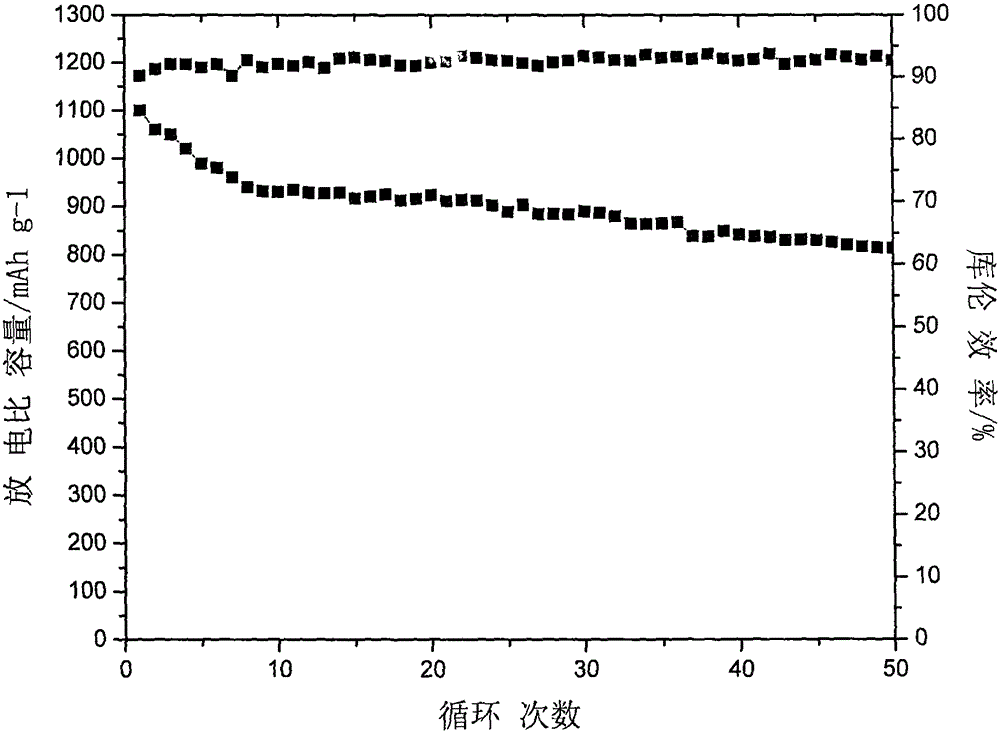

[0022] Weigh 0.24g BP2000 and 0.12g AlI3, mix them in a mortar and grind them evenly, then pour them into a reaction bottle containing 0.04g binder PVDF dispersed with 8g dispersant, and stir at room temperature for 12h. After the slurry is evenly stirred, use a film applicator with a suitable thickness to coat evenly on one side of the diaphragm. Generally, after the coated diaphragm is naturally dried, it is placed in a vacuum oven at 60°C for 12 hours, and the baked diaphragm is cut. Form a disc with a diameter of Φ19mm, weigh and number it to prepare a separator with a functional protective coating, and then assemble a lithium-sulfur battery to test the relevant electrochemical performance. 100mAg at room temperature -1 The charge and discharge test is carried out under the current density, and the first discharge specific capacity is 1090.4mAhg -1 , 50 discharge capacity 804.6mAhg -1 , 50 times the capacity retention rate was 73.8%, and the average Coulombic efficiency ...

Embodiment 3

[0024] Weigh 0.28gAl2 o 3 and 0.08gLiNO 3 , mix it in a mortar and grind it evenly, then pour it into a reaction bottle containing 0.04g binder PTFE dispersed with 5g dispersant, and stir at room temperature for 12h. After the slurry is evenly stirred, use a film applicator with a suitable thickness to coat evenly on one side of the diaphragm. Generally, after the coated diaphragm is naturally dried, it is placed in a vacuum oven at 60°C for 12 hours, and the baked diaphragm is cut. Form a disc with a diameter of Φ19mm, weigh and number it to prepare a separator with a functional protective coating, and then assemble a lithium-sulfur battery to test the relevant electrochemical performance. 100mAg at room temperature -1 The charge and discharge test is carried out under the current density, and the specific capacity of the first discharge is 1052.8mAhg -1 , 50 discharge capacity 810.6mAhg -1 , The 50-time capacity retention rate is 77.0%, and the first-time average Coulomb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com