Soft package battery and manufacturing process therefor

A technology of soft pack battery and manufacturing process, which is applied in secondary battery manufacturing, printed circuit manufacturing, sustainable manufacturing/processing, etc. It can solve problems that affect customer safety, product safety, easy formation of burrs and corners, and damage to soft packaging. , to achieve the effect of improving product quality, reducing manufacturing process steps, and facilitating separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

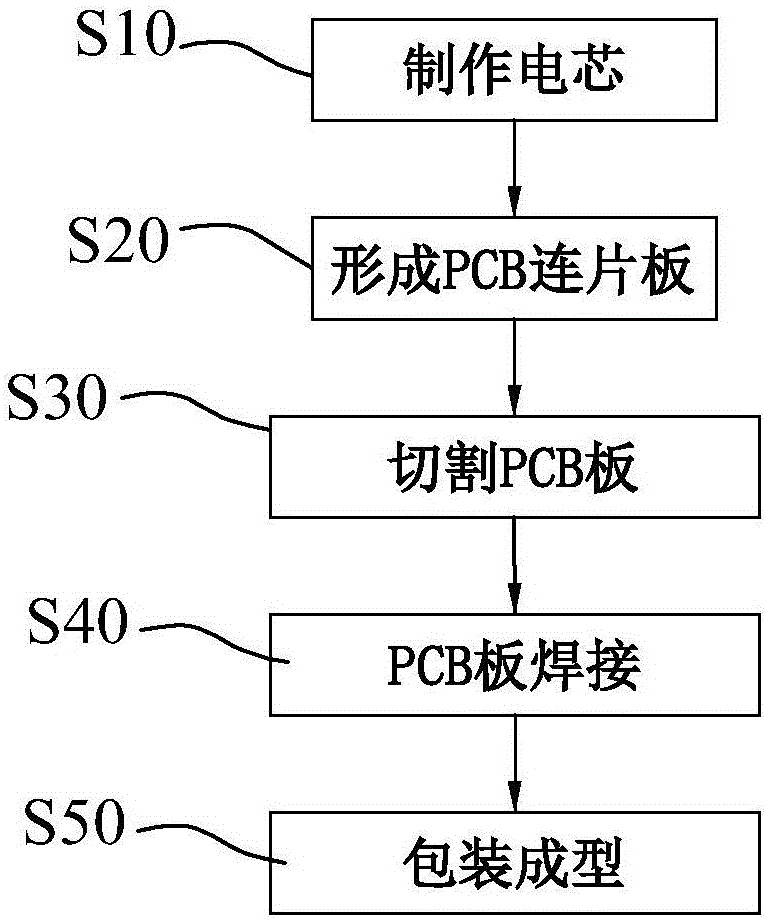

[0025] see figure 1 , showing the manufacturing process of the pouch battery according to the embodiment of the present invention, which includes the following steps:

[0026] S10, making a cell: the cell includes a cell body and exposed positive and negative tabs;

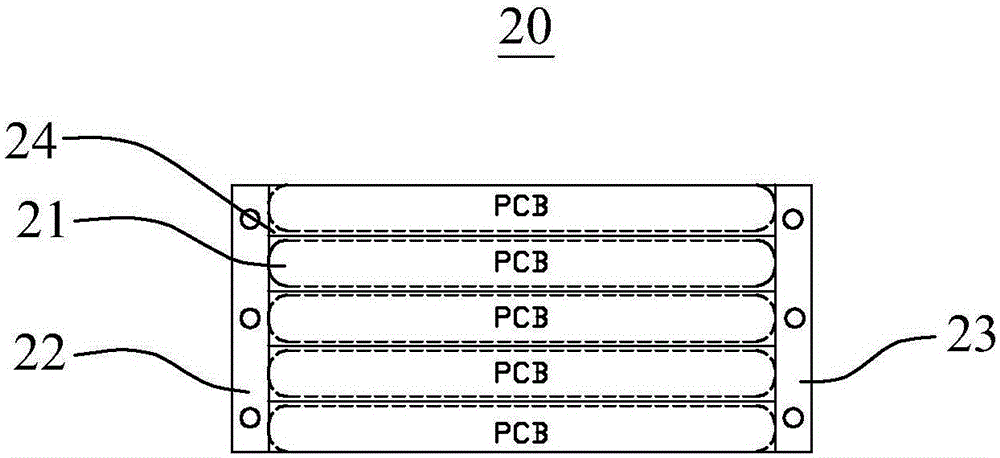

[0027] S20, forming a PCB connecting board: the PCB connecting board includes two side frames and a plurality of PCB boards connected together, the multiple PCB boards are arranged in parallel and each two ends are connected to the two side frames;

[0028] S30, cutting the PCB board: cutting the PCB connecting board, cutting off the material between the PCB ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com