A method of intensive roasting to reduce ash hanging on upper leaves of k326

A technology of intensive baking and tobacco leaves, which is applied in the direction of tobacco preparation, application, tobacco, etc., can solve the problems of insufficient softness of leaves, difficulty in dehydration of upper leaf tobacco leaves, and low degree of softness of branch veins, so as to reduce the risk of hanging ash smoke Occurrence, reduce the difficulty of baking, promote the effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

[0023] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. The specific steps include:

[0024] During the season of tobacco leaf curing, the collected fresh upper tobacco leaves of K326 are smoked through braiding rods or tobacco clamps, and then roasted in a standard dense barn. Two dry and wet bulb thermometers are placed in the high temperature layer and the middle layer respectively.

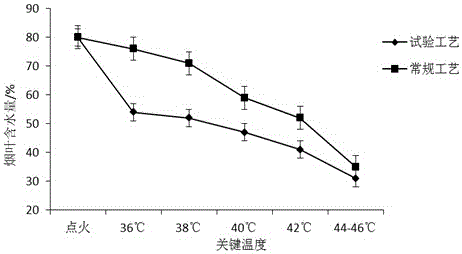

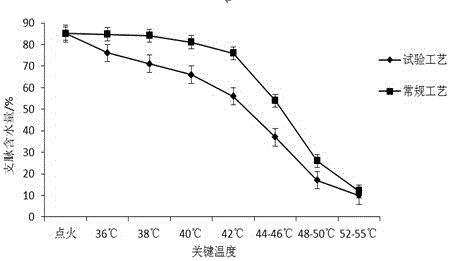

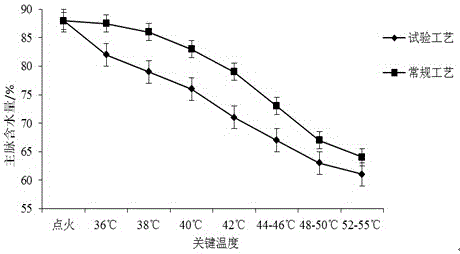

[0025] (1) Dehydration in the early stage of yellowing, so that the tobacco leaves collapse and the branches become soft: after the tobacco is loaded and ignited, the temperature of the dry bulb is raised to 40-42°C at 1-2°C / h, without dehum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com