Baking method capable of improving softness of upper tobacco of flue-cured tobacco

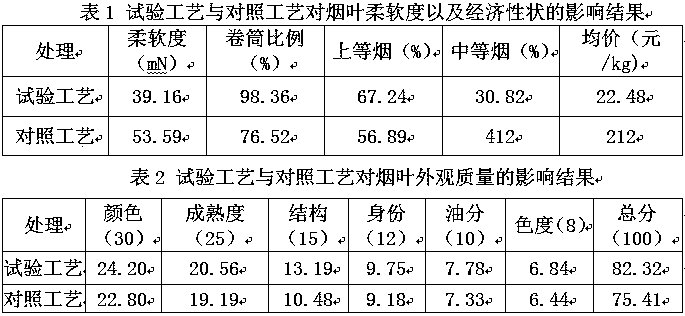

A curing method and softness technology, which is applied in the field of upper tobacco leaf curing in the air-flow descending intensive curing barn, can solve the problems of adverse effects on the appearance and internal quality of the upper leaves, ash hanging on the tobacco leaves, and insufficient porosity of the tobacco leaf structure, etc., and achieve variable The drying process of yellowing and dehydration is coordinated and reasonable, the porosity and softness of leaves are improved, and the shrinkage of tobacco leaves is obvious.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below with the example of baking upper tobacco leaves.

[0041] Ⅰ. Tobacco weaving and roasting: When weaving tobacco, weaving 150 pieces of tobacco per rod, 2 pieces in a bunch, back to back. When loading the tobacco, it should be filled, densely packed and evenly packed, and the large-scale airflow descending intensive curing barn can hold 380 rods of tobacco.

[0042] Ⅱ. Installation of curing room equipment: three layers and two channels are used for hanging smoke, and a temperature and humidity sensor is installed in the middle of the middle layer; a 4 / 8 pole-changing speed-regulating motor and a No. Axial flow fan, when the axial flow fan is running at high speed, it runs with 4 poles, and the speed is 1440 rpm; when it runs at low speed, it runs with 8 poles, and the speed is 720 rpm; A cold air door is installed on the lower part of the front wall of the heating chamber.

[0043] Ⅲ. Baking operation:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com