A detection method for formula granules of Maxing Shigan Decoction

A technology of Maxing Shigan Decoction and formula granules, which is applied in the field of preparation of Maxing Shigan Decoction formula granules, to achieve the effect of reducing the floating of ephedra and controlling the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

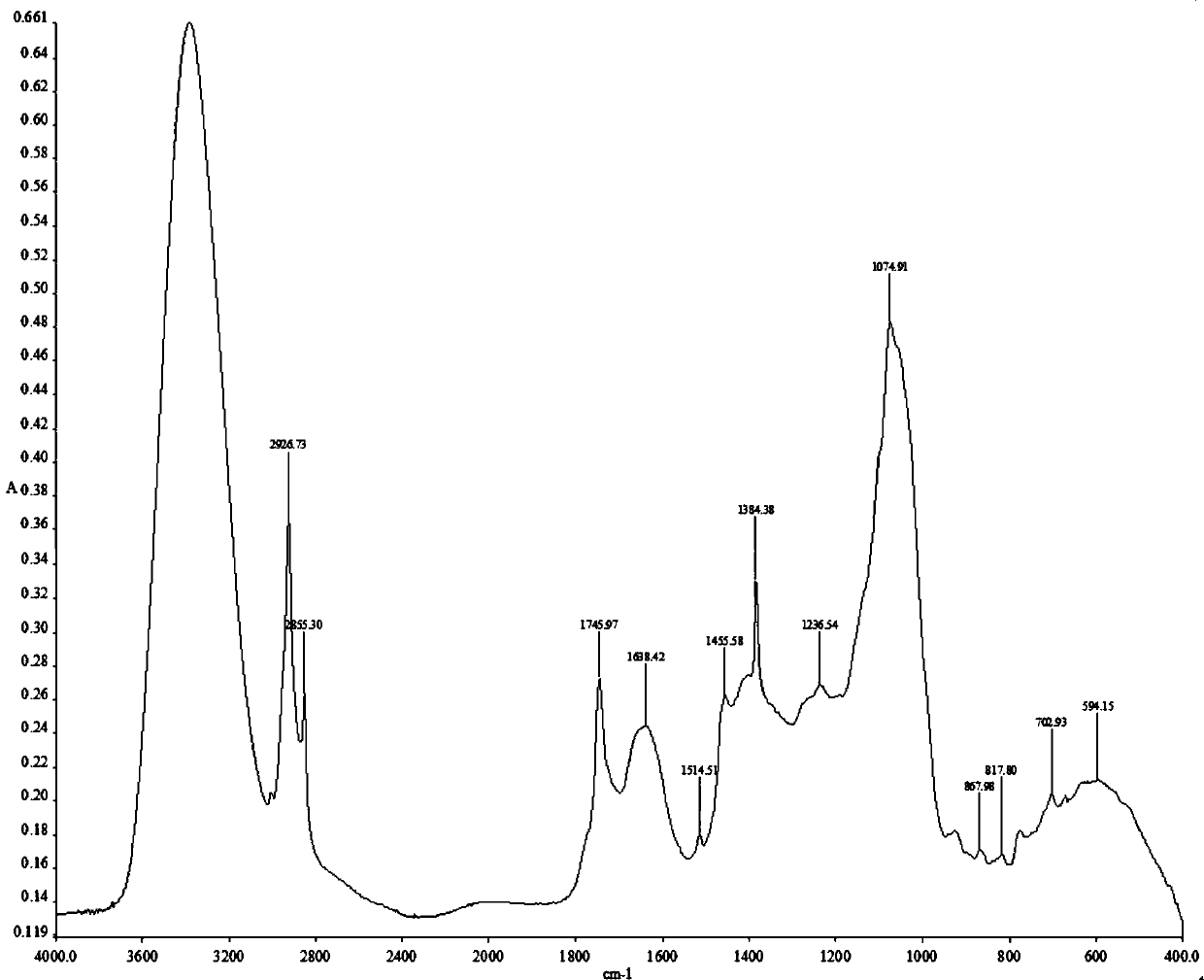

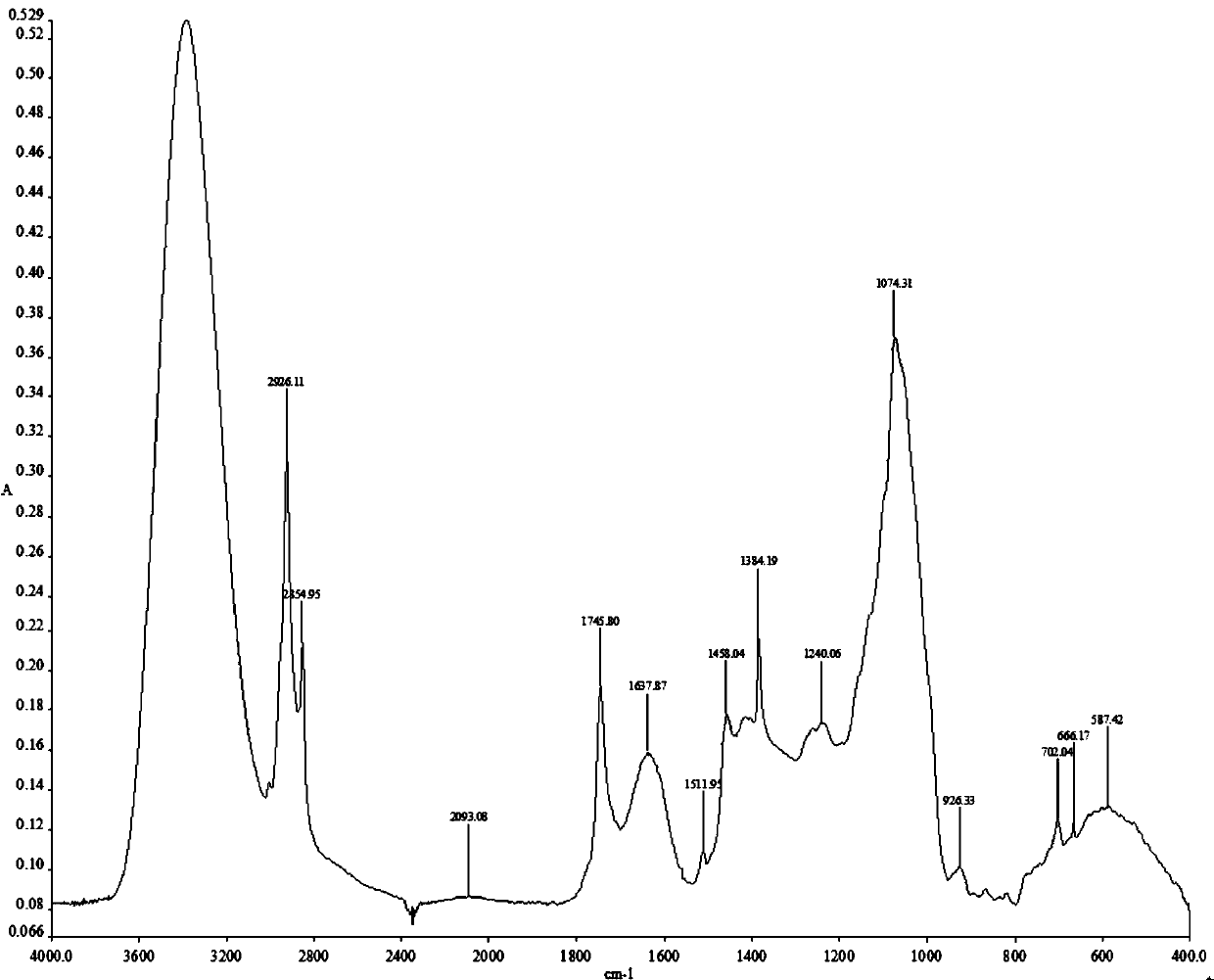

Image

Examples

Embodiment 1

[0051] A preparation method of Maxing Shigan Decoction formula granules, comprising the steps of:

[0052] a. Take 49.9kg of water, boil it, add 1070g of ephedra, 1070g of bitter almond, 710g of roasted licorice, and then add 2140g of gypsum, decoct and extract for 1 hour, that is, decoct once; after decocting, add 44.91kg of water to the dregs of the medicine, decoct Extract for 1 hour, that is, fry for the second time;

[0053] b. Combine the two decoction filtrates, filter, and concentrate the filtrate under reduced pressure under vacuum to a concentrated solution with a relative density of 1.04 at 95°C;

[0054] c. Take the above concentrate and spray dry it. Control the air inlet temperature at 175°C-185°C and the outlet air temperature at 85-95°C to obtain a spray-dried powder. Add an appropriate amount of maltodextrin to the spray-dried powder for dry granulation to obtain a particle size of 16-40 Formula granules of Maxing Shigan Decoction with uniform color and luste...

Embodiment 2

[0058] A preparation method of Maxing Shigan Decoction formula granules, comprising the steps of:

[0059] a. Take 31.88kg of water, boil it, put in 535g of ephedra, 535g of bitter almond, 355g of roasted licorice, and then put in 700g of gypsum, decoct for extraction for 1.5 hours, that is, decoct once; after decocting, add 21.25kg of water to the dregs of the medicine, decoct Extract for 1 hour, that is, fry for the second time;

[0060] b. Combine the two decoction filtrates, filter, and concentrate the filtrate under reduced pressure under vacuum to a concentrated solution with a relative density of 1.02 at 95°C;

[0061] c. Take the above concentrate and spray dry it. Control the air inlet temperature at 175°C-185°C and the outlet air temperature at 85-95°C to obtain a spray-dried powder. Add an appropriate amount of maltodextrin to the spray-dried powder for dry granulation to obtain a particle size of 16-40 Formula granules of Maxing Shigan Decoction with uniform color...

Embodiment 3

[0065] A preparation method of Maxing Shigan Decoction formula granules, comprising the steps of:

[0066] a. Take 14.97kg of water, boil it, put in 321g of ephedra, 321g of bitter almond, 213g of roasted licorice, and then put in 642g of gypsum, decoct for extraction for 2 hours, that is, decoct once; after decocting, add 7.49kg of water to the dregs of the medicine, decoct Extract for 0.5 hours, that is, fry for the second time;

[0067] b. Combine the two decoction filtrates, filter, and concentrate the filtrate under reduced pressure under vacuum to a concentrated solution with a relative density of 1.06 at 95°C;

[0068] c. Take the above concentrate and spray dry it. Control the air inlet temperature at 175°C-185°C and the outlet air temperature at 85-95°C to obtain a spray-dried powder. Add an appropriate amount of maltodextrin to the spray-dried powder for dry granulation to obtain a particle size of 16-40 Formula granules of Maxing Shigan Decoction with uniform color...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com