Preparation method for silver-loaded N-doped graphene, and application of silver-loaded N-doped graphene in metal-air battery catalyst

A technology of nitrogen-doped graphene and sulfonated graphene, which is applied in the direction of physical/chemical process catalysts, battery electrodes, chemical instruments and methods, etc. It can solve the problems of difficult to meet environmental protection requirements, low nitrogen doping amount, and harsh reaction conditions and other issues to achieve the effect of aerobic reduction catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The embodiment of the present invention discloses a method for preparing silver-loaded nitrogen-doped graphene, comprising:

[0039] Silver nitrate, ammonia water and functionalized graphene solution are mixed and placed in a high-temperature reactor, and reacted at 100-200°C for 1-12 hours to obtain silver-loaded nitrogen-doped graphene;

[0040] The functionalized graphene is selected from one or more of graphene oxide, sulfonated graphene, aminated graphene, polyacrylic acid modified graphene oxide and polyacrylamide modified graphene oxide;

[0041]The concentration of the functionalized graphene solution is 0.5-10 mg / mL.

[0042] This application adopts a one-step method to synthesize silver-loaded nitrogen-doped graphene. In addition, the nitrogen-doping reaction temperature is low, and the nitrogen content is high, and the experimental process is simple and easy to implement.

[0043] According to the present invention, the raw materials are first mixed, and the...

Embodiment 1

[0065] Dissolve 50mg of silver nitrate with an appropriate amount of deionized water, add excess ammonia water to adjust the pH of the solution to 12-13, it can be observed that the transparent solution first forms a brown precipitate, and then the precipitate becomes a transparent solution again, and then add 10ml with a concentration of 1mg / ml homogeneous graphene oxide solution; then the obtained mixture was ultrasonically cleaned for 1h with an ultrasonic cleaner, and then the aqueous solution of the mixture was added to a high-temperature reactor to react for 12h at a temperature of 200°C, and the obtained product was washed with deionized water Several times until the pH of the clear liquid is neutral; finally, the washed product is lyophilized to obtain the final product, namely silver-loaded nitrogen-doped graphene.

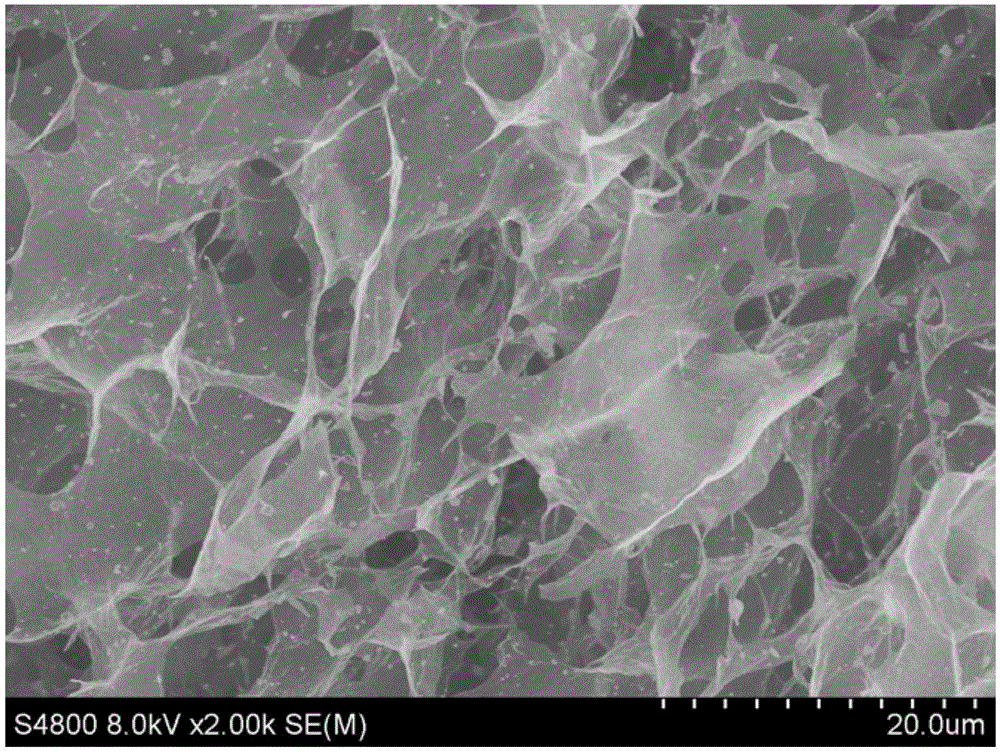

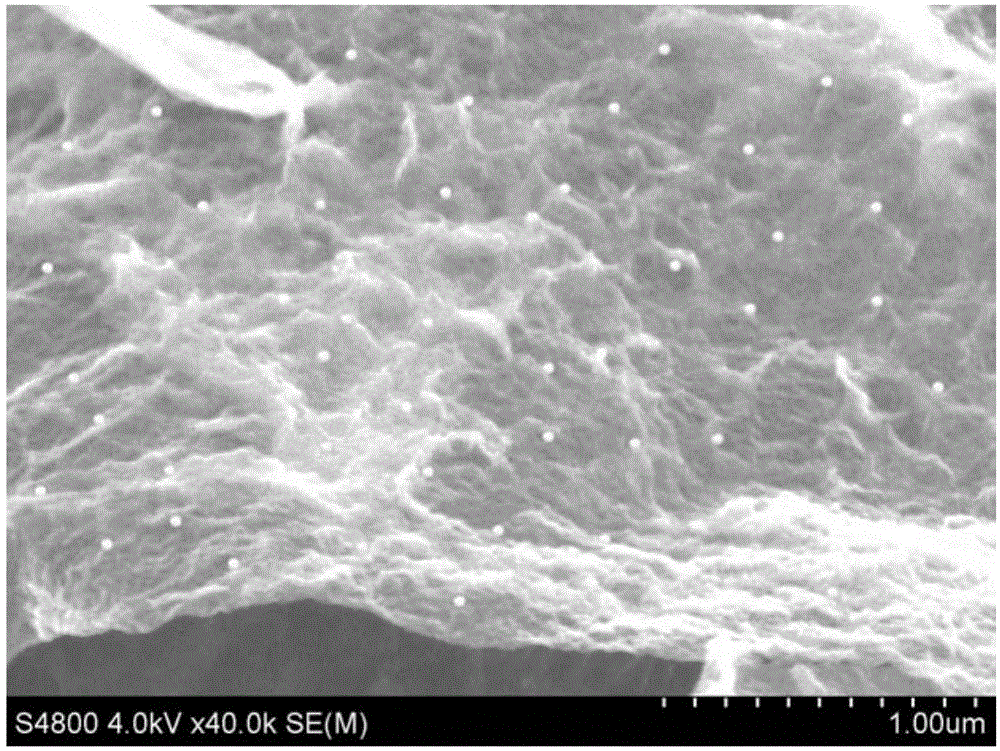

[0066] figure 1 For the scanning electron micrograph of the nitrogen-doped graphene loaded with silver prepared in this embodiment, it can be seen that t...

Embodiment 2

[0072] Dissolve 100mg of silver nitrate with an appropriate amount of deionized water, add excess ammonia water to adjust the pH of the solution to 12-13, it can be observed that the transparent solution first forms a brown precipitate, and then the precipitate becomes a transparent solution, and then add 20ml of the concentration of 5mg / ml homogeneous graphene oxide solution; then the mixture is ultrasonically cleaned for 1h, then the aqueous solution of the mixture is added to a high-temperature reactor and reacted for 1h at a temperature of 160°C, and the obtained product is washed several times with deionized water until the pH of the clear liquid is neutral; finally, the washed product is lyophilized to obtain the final product, namely silver-loaded nitrogen-doped graphene.

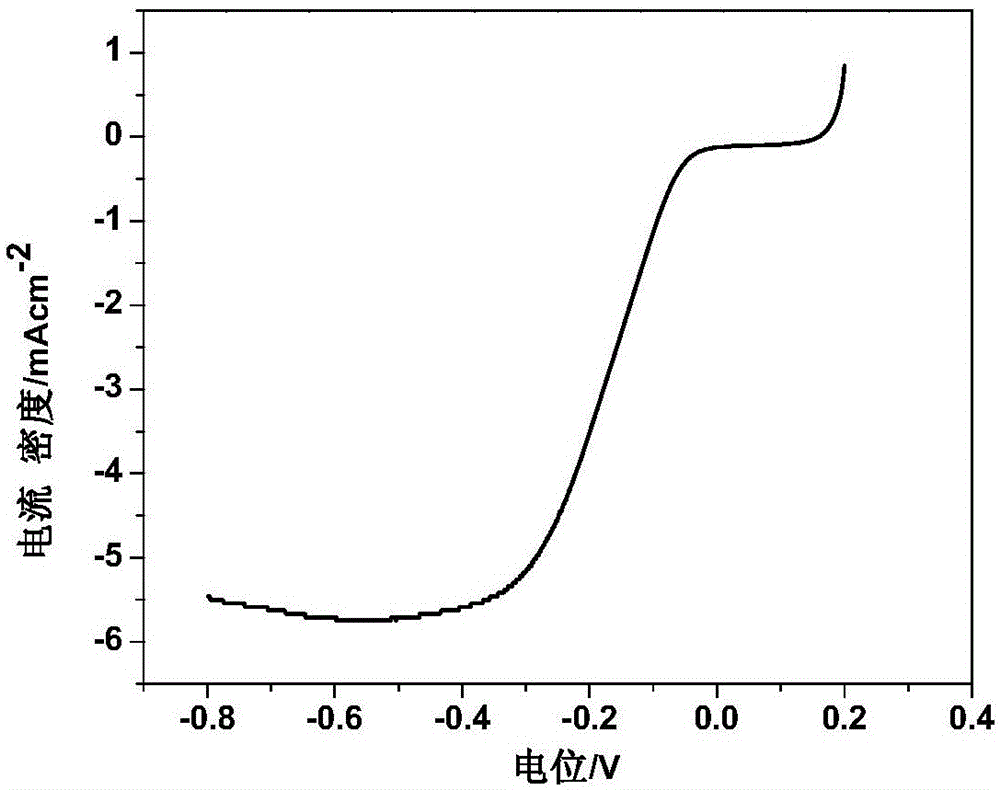

[0073] Figure 7 The battery performance tested for the catalyst as a battery device, in Fig. The curve is the battery performance curve of the catalyst of this example. It can be seen that the cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com