Nitrogen-doped graphene hollow microsphere (NGHM) preparation method

A technology of nitrogen-doped graphene and hollow spheres, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of cumbersome steps and achieve unique hollow structure, high stability and toxicity resistance, good stability and toxicity resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment one: concrete steps are as follows:

[0017] 1) Preparation of graphene: Prepared by the Hummers method and obtained a highly dispersed oxygen-reduced graphene GON with a solid content of 0.1 mg / mL through ultrasound;

[0018] 2) Mix 4mL commercial polystyrene microspheres (Aladdin Reagent (Shanghai Co., Ltd.)) with 100mL GON dispersion, add 500mL distilled water, and stir overnight;

[0019] 3) Add 3 g of melamine to the mixture in step 2), stir overnight, and freeze-dry;

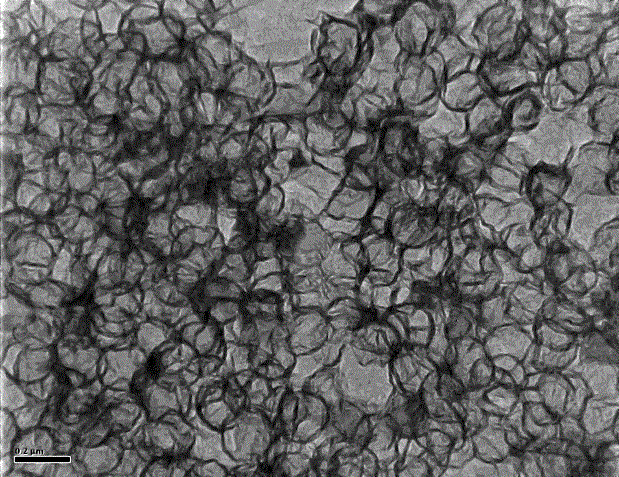

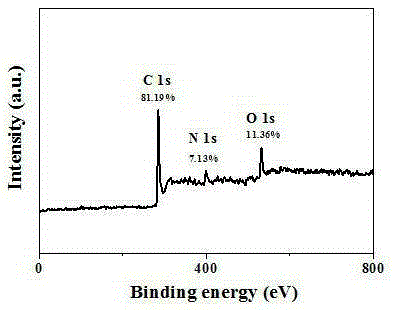

[0020] 4) The product in step 3) was calcined at 800°C under the protection of nitrogen gas, kept for 2 hours, and naturally cooled to room temperature to obtain NGHM. figure 1 is the transmission electron microscope image of NGHM, figure 2 It is the X-ray photoelectron spectrum of NGHM, which proves that NGHM is a hollow spherical structure doped with nitrogen.

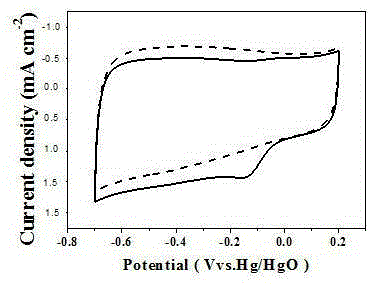

[0021] 5) Using Hg / HgO as the reference electrode, platinum wire as the counter electrode, NGHM-modified glassy carbon e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com