Method for preparing cathode material of hollow spherical copper phosphide lithium battery

A technology of cuprous phosphide and negative electrode material, applied in battery electrodes, phosphide, circuits, etc., can solve the problems of irregular product particles, expensive equipment, slow diffusion of lithium ions, etc., achieving low cost, simple preparation process, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

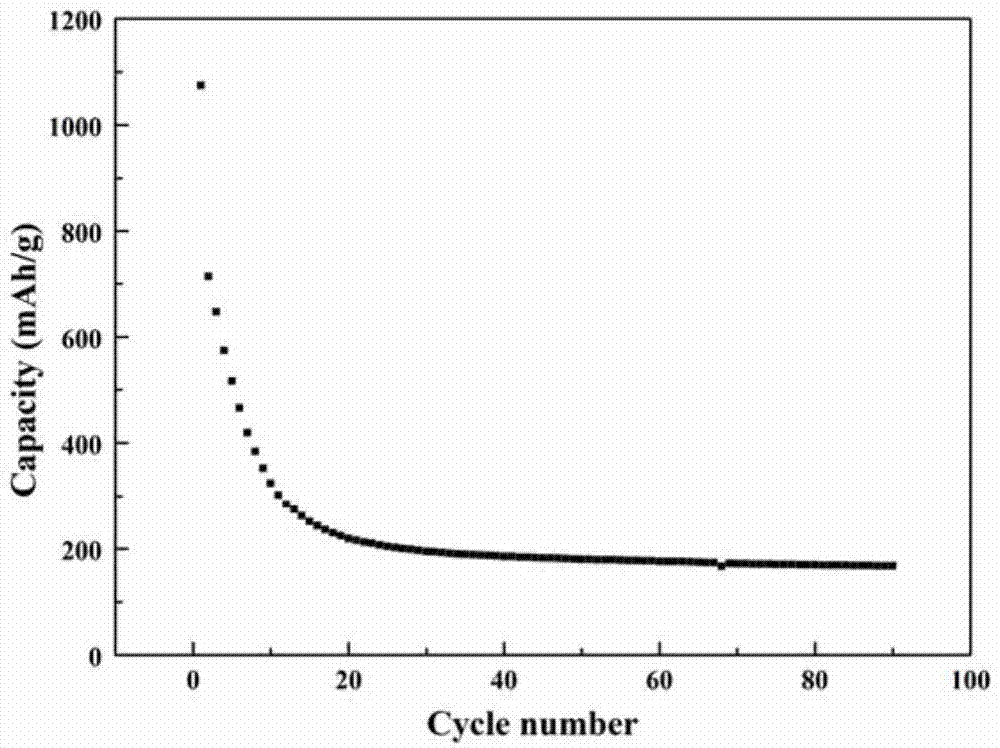

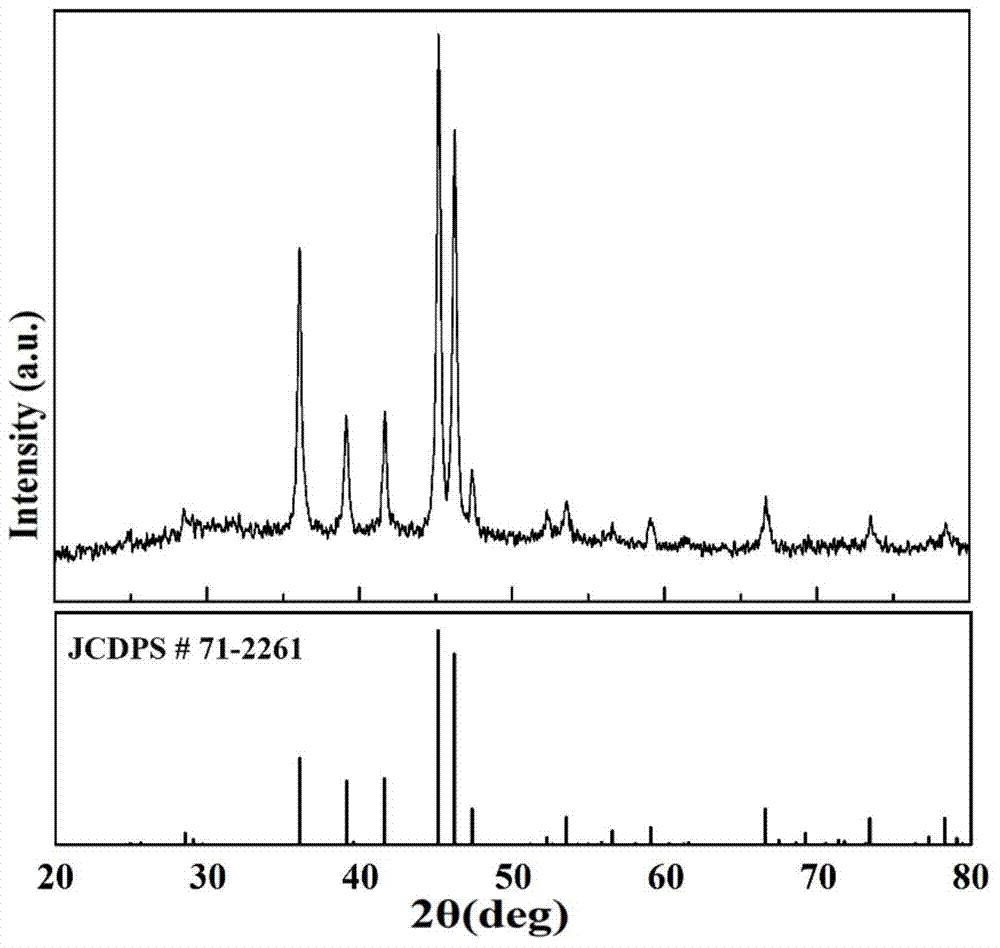

[0029] A method for preparing hollow spherical cuprous phosphide nano-micron lithium battery anode material includes the following steps:

[0030] 1) Add 40mL of deionized water to the autoclave, and add 0.078g of copper sulfate to each milliliter of the solution until the solid is completely dissolved to form a blue transparent solution with a filling degree of 80%;

[0031] 2) Add 0.01g EDTA sodium salt and 0.006g PEG-10000 to each ml of blue transparent solution obtained in step 1), and stir until completely dissolved;

[0032] 3) Transfer the transparent solution obtained in step 2) into a polytetrafluoroethylene lining, and then add 0.01g of yellow phosphorus to each milliliter of the transparent solution, and then seal the polytetrafluoroethylene lining into a stainless steel mold. Under the conditions, start heating from room temperature and heat at 200℃ for 16h;

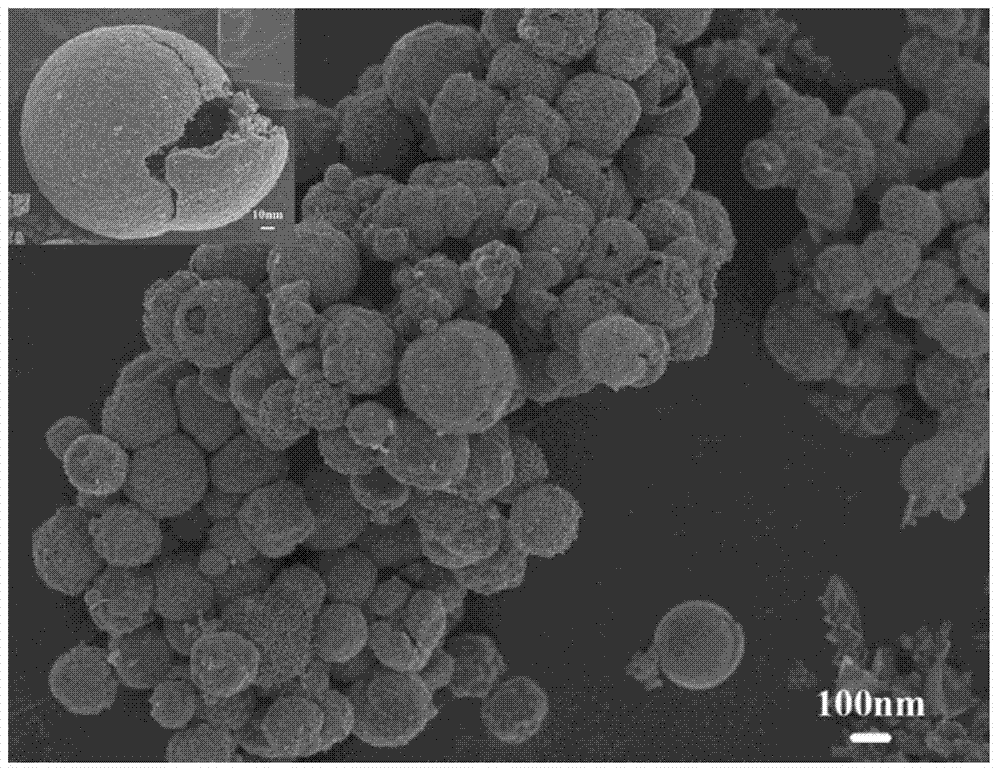

[0033] 4) After the reaction is completed, cool to room temperature with the furnace, and then filter with fast qu...

Embodiment 2

[0038] The volume of step 1) deionized water in Example 1 was changed to 30 mL, the filling degree was changed to 60%, and other conditions were unchanged. The hollow sphere size of the product was larger than that in Example 1, see Figure 4 , Figure 4 This is the SEM image of the hollow spherical cuprous phosphide of Example 2.

Embodiment 3

[0040] The reaction temperature of step 3) in Example 1 was changed to 160° C., other conditions were unchanged, and the obtained product was spherical, but compared with Example 1, the proportion of spherical occupancy was lower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com