A kind of hollow carbon tube composite material and its preparation method and application

A composite material and hollow carbon technology, applied in electrolytic components, electrodes, electrolytic processes, etc., can solve the problems of low efficiency of non-precious metal catalysts, power consumption bottlenecks, etc., and achieve good application prospects, short reaction time, and accelerated permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Preparation of Co nanoparticle-loaded hollow carbon tube composite material Co / KF

[0024] (1) Take 2.0 g cotton (KF) and add it to 150 ml NaClO 2 (1 wt %) solution, magnetically stirred for 10 minutes, and then the suspension was refluxed at 120 °C for 4 h to remove the wax protective layer attached to the cotton surface, then separated by suction filtration, washed with distilled water several times, and dried overnight at 60 °C to obtain a hollow Carbon tube material KF.

[0025] (2) Take 0.9 g of the hollow carbon tube material KF prepared in step (1) and immerse in 10 ml of CoCl 2 (5 wt %) solution, the hollow carbon tube material KF completely absorbs CoCl 2 The solution was dried overnight at 60 °C and placed in a tube furnace in a hydrogen-argon mixture at 5 °C min -1 The heating rate was increased from room temperature to 800 °C and calcined for 4 h to obtain the final product Co / KF composite.

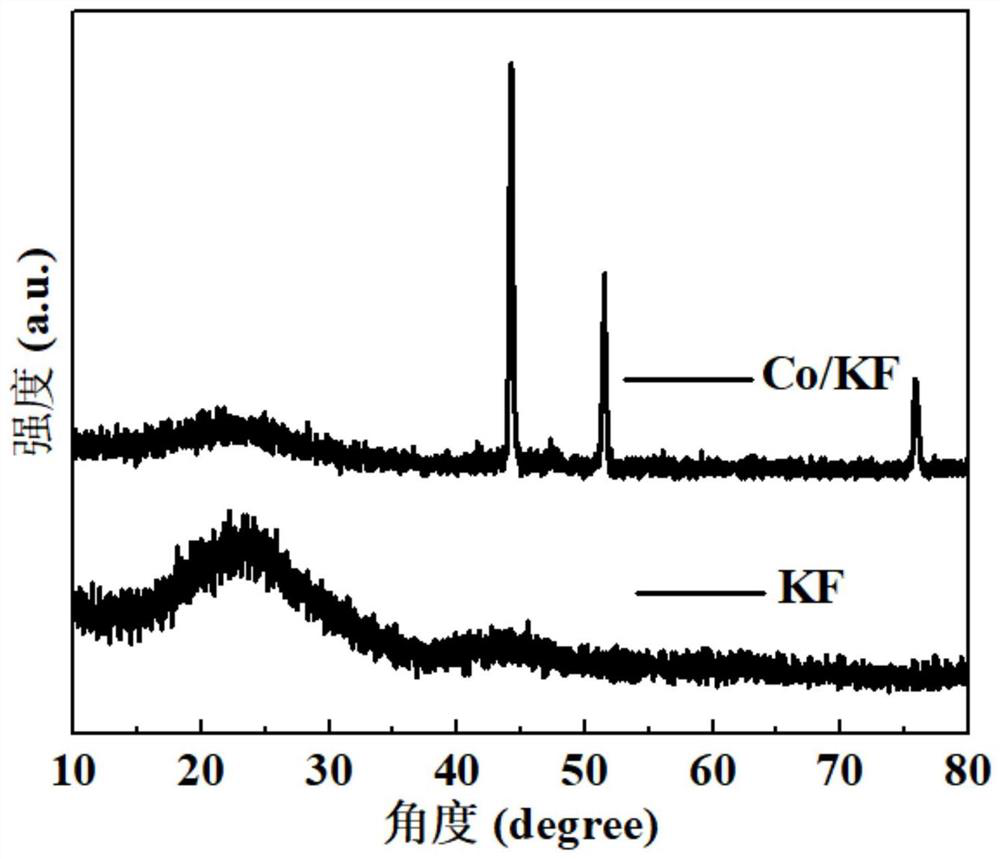

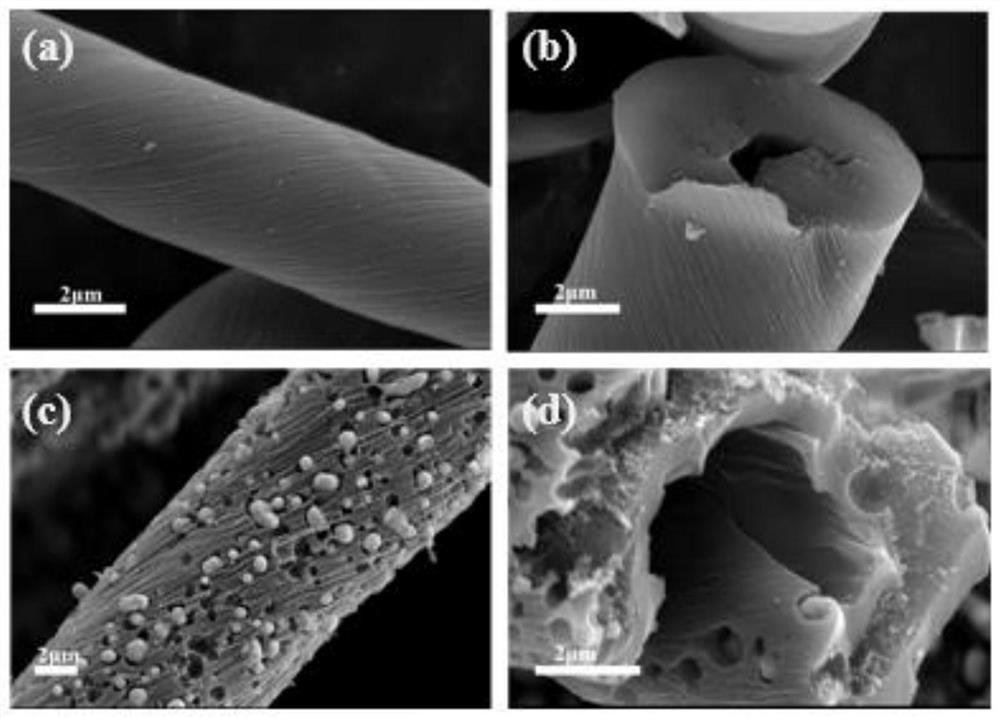

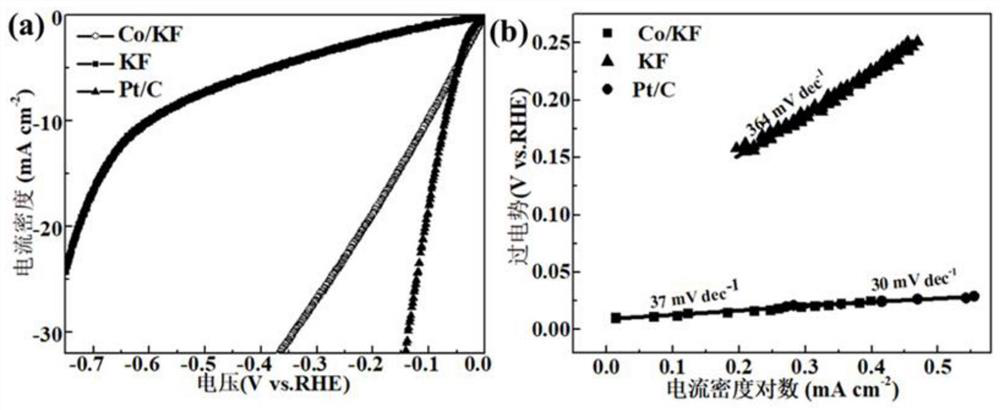

[0026] The prepared product Co / KF was characteriz...

Embodiment 2

[0027] Example 2: Preparation of Co nanoparticle-loaded hollow carbon tube composite material Co / KF

[0028] (1) Take 4.0 g cotton (KF) and add it to 300 ml NaClO 2 (2wt%) solution, after magnetic stirring for 10 minutes, the suspension was refluxed at 100 ° C for 5 h to remove the wax protective layer on the cotton surface, then separated by suction filtration, washed with distilled water for many times, dried at 50 ° C for 12 h to obtain the processed Hollow carbon tube material KF.

[0029] (2) Take 0.9 g of the hollow carbon tube material KF prepared in step (1) and immerse in 12ml of CoCl 2 (5 wt %) solution, the hollow carbon tube material KF completely absorbs CoCl 2 The solution was dried overnight at 70 °C and placed in a tube furnace in a hydrogen-argon mixture at 2 °C min -1 The heating rate was increased from room temperature to 900 °C and calcined for 3 h to obtain the final product Co / KF composite material.

Embodiment 3

[0030] Embodiment 3: Preparation of Co nanoparticle loaded hollow carbon tube composite material Co / KF

[0031] (1) Take 2.0 g cotton (KF) and add it to 150 ml NaClO 2 (3 wt %) solution, after magnetic stirring for 10 minutes, the suspension was refluxed at 150 °C for 3 h to remove the wax protective layer on the cotton surface, then separated by suction filtration, washed with distilled water several times, and dried overnight at 60 °C to obtain a good Hollow carbon tube material KF.

[0032] (2) Take 0.9 g of the hollow carbon tube material KF prepared in step (1) and immerse in 21 ml of CoCl 2 (3wt%) solution, the hollow carbon tube material KF completely absorbs CoCl 2 The solution was dried overnight at 60 °C and placed in a tube furnace in a hydrogen-argon mixture at 5 °C min -1 The heating rate was increased from room temperature to 700 °C and calcined for 5 h to obtain the final product Co / KF composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com