A kind of nanometer silver hollow microsphere/pvdf ultrafiltration membrane and preparation method thereof

A technology of hollow microspheres and nano-silver, which is applied in the direction of microsphere preparation, ultrafiltration, microcapsule preparation, etc., to achieve the effects of improved service life, good surface permeability, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

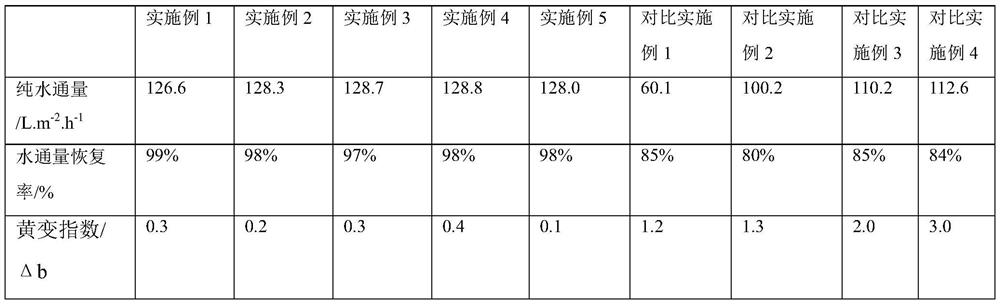

Examples

Embodiment 1

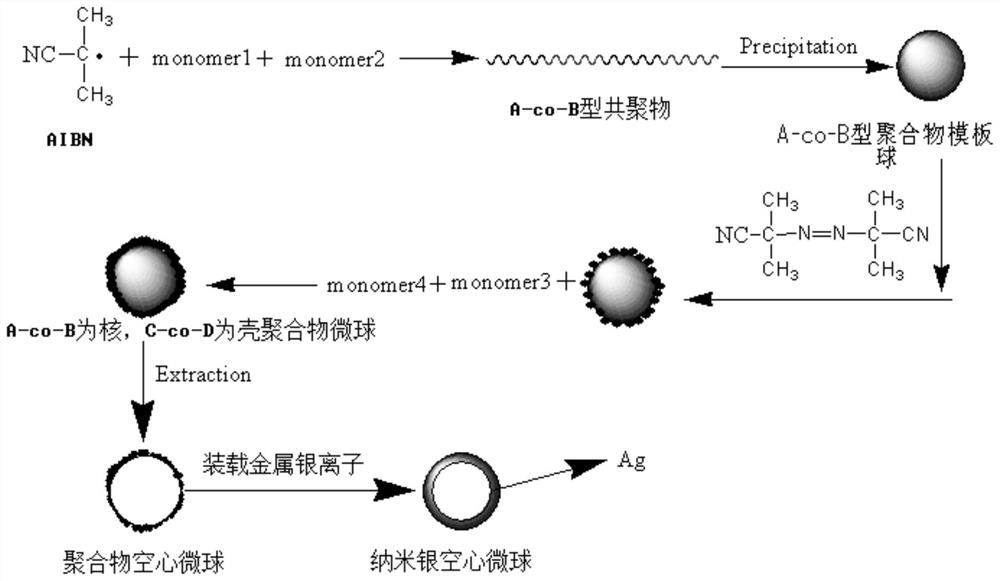

[0040] The specific preparation method of nano-silver hollow microspheres is as follows:

[0041] The first step is the preparation of polymer microspheres.

[0042] (1) First prepare the template ball, the specific experimental steps are as follows:

[0043] Using dimethylacetamide as solvent, azobisisobutyronitrile as initiator, and A and B (the molar ratio of A and B is 2:8, wherein, A is methyl methacrylate, B is butyl methacrylate Esters) are mixed and added dropwise into the reactor for free radical copolymerization reaction to generate polymethyl methacrylate-co-butyl methacrylate copolymer. The reaction temperature is 70°C and the reaction time is 8h. During the whole reaction process, Nitrogen protection. Wherein, the amount of azobisisobutyronitrile is 0.3% of the total mass of the monomer, and the monomer dissolved in the solvent is dropped into the reactor at a rate of 40 drops / min. After the reaction, the product was washed three times with petroleum ether and ...

Embodiment 2

[0057] The specific preparation method of nano-silver hollow microspheres is as follows:

[0058] The first step is the preparation of polymer microspheres.

[0059] First prepare the template spheres. The specific experimental steps are as follows: using dimethylacetamide as a solvent, azobisisoheptanonitrile as an initiator, and A and B (the molar ratio of A and B is 5:5, wherein A is 2-methyl methacrylate , B is ethyl methacrylate, isobornyl methacrylate) mixed and added dropwise to the reactor for free radical copolymerization to generate poly 2-methyl methacrylate-co-isobornyl methacrylate copolymer , the reaction temperature is 75° C., the reaction time is 9 h, and the nitrogen gas is protected during the whole reaction process. Wherein, the amount of azobisisoheptanonitrile is 0.4% of the total mass of the monomers, and the monomers dissolved in the solvent are dripped into the reactor at a rate of 50 drops / min. After the reaction, the product was washed three times ...

Embodiment 3

[0072] The specific preparation of nano silver hollow microspheres is as follows:

[0073] The first step is the preparation of polymer microspheres.

[0074] (1) First prepare the template ball, the specific experimental steps are as follows:

[0075] Use dimethylacetamide as solvent and azobisisobutyronitrile as initiator, mix with A and B (the molar ratio of A and B is 8:2, where A is methyl acrylate, B is ethyl acrylate) and drop Add it into the reactor for free radical copolymerization reaction to form polymethyl acrylate-co-ethyl acrylate copolymer, the reaction temperature is 80°C, the reaction time is 10h, and the nitrogen is protected during the whole reaction process. Wherein, the amount of azobisisobutyronitrile is 5‰ of the total mass of the monomer, and the monomer dissolved in the solvent is dripped into the reactor at a rate of 60 drops / min. After the reaction, the product was washed three times with petroleum ether and deionized water respectively, and dried ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com