Porous carbon-based nanofiber thin film material loaded by metal monatomic and metal derivative thereof as well as preparation method and application thereof

A technology of metal derivatives and nanofibers, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of high cost, slow cathode oxygen reduction reaction, low reserves, etc., and achieve utilization High, simple method, high specific surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Metal salt Zn(NO 3 ) 2 Dissolve in methanol with 2-methylimidazole respectively, stir and mix at room temperature, wash the centrifuged product with methanol, and obtain white powder solid ZIF-8 after vacuum drying;

[0046] The obtained ZIF-8 was dissolved in N,N-dimethylformamide and stirred well at room temperature to form a white solution. The polymer polyacrylonitrile PAN is added to the above solution, fully stirred and mixed for more than 24 hours, and the spinning solution is prepared. By using electrospinning technology, ZIF-8 nanoparticles doped polymer fiber film PAN / ZIF-8 was obtained;

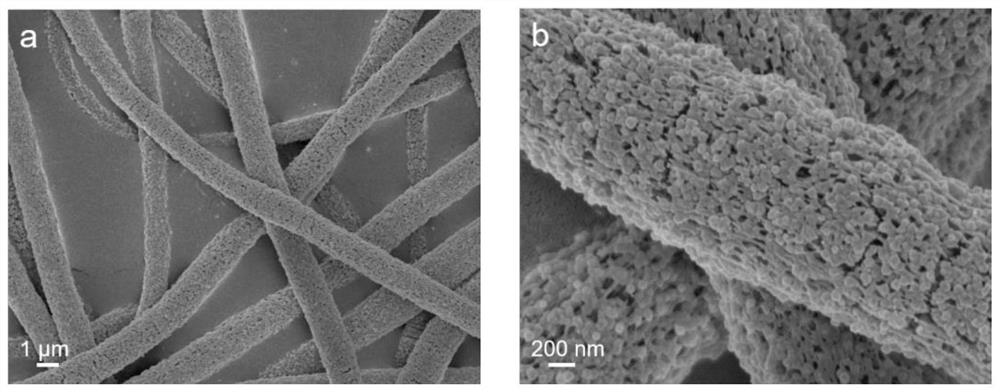

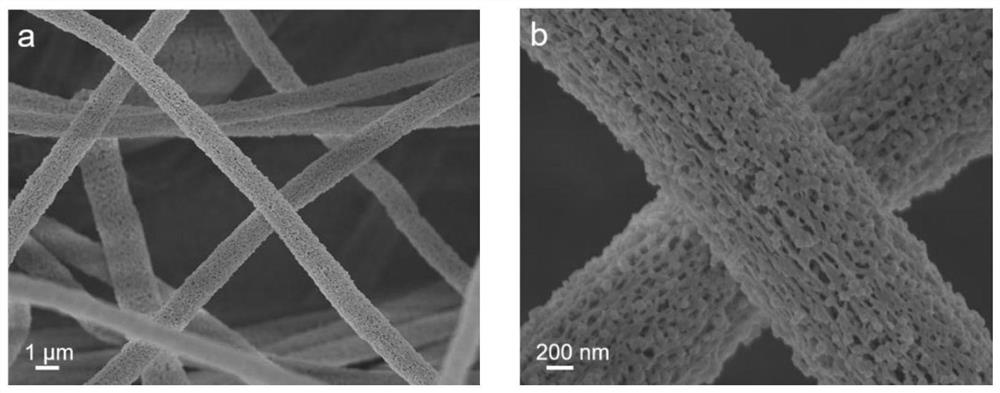

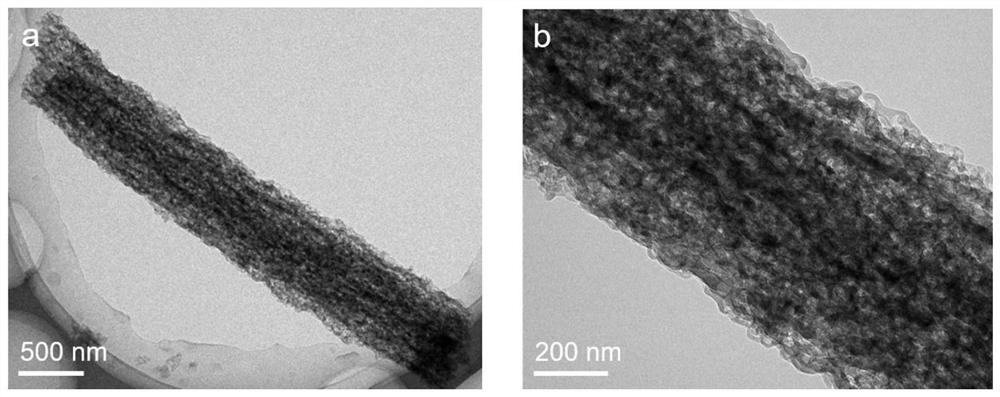

[0047] Put the fibrous membrane PAN / ZIF-8 in 0.1~1g L -1 Fe(NO 3 ) 3 In the methanol solution, soak for 1-5 hours and then vacuum-dry to obtain PAN / ZIF-8 / Fe adsorbed by metal ions, and then perform heat treatment at a heating rate of 2-10°C / min, and the speed of heating is ≥500°C, and keep for 1-5h , to obtain metal single atom-supported nitrogen-doped carbon nanofibe...

Embodiment 2

[0049] Metal salt Zn(NO 3 ) 2 Dissolve in methanol with 2-methylimidazole respectively, stir and mix at room temperature, wash the centrifuged product with methanol, and obtain white powder solid ZIF-8 after vacuum drying;

[0050] The obtained ZIF-8 was dissolved in N,N-dimethylformamide and stirred well at room temperature to form a white solution. The polymer polyacrylonitrile PAN is added to the above solution, fully stirred and mixed for more than 24 hours, and the spinning solution is prepared. By using electrospinning technology, ZIF-8 nanoparticles doped polymer fiber film PAN / ZIF-8 was obtained;

[0051] Place the fibrous membrane PAN / ZIF-8 in 0.5g L -1 Fe(NO 3 ) 3 in methanol solution, soaked for 3 hours and then vacuum-dried to obtain PAN / ZIF-8 / Fe adsorbed by metal ions, followed by heat treatment at a heating rate of 5°C / min, at a rate of 800°C, and kept for 3h to obtain metal single-atom-supported nitrogen Doped carbon nanofibers SA-Fe-N-C.

Embodiment 3

[0053] Metal salt Zn(NO 3 ) 2 Dissolve in methanol with 2-methylimidazole respectively, stir and mix at room temperature, wash the centrifuged product with methanol, and obtain white powder solid ZIF-8 after vacuum drying;

[0054] The obtained ZIF-8 was dissolved in N,N-dimethylformamide and stirred well at room temperature to form a white solution. The polymer polyacrylonitrile PAN is added to the above solution, fully stirred and mixed for more than 24 hours, and the spinning solution is prepared. By using electrospinning technology, ZIF-8 nanoparticles doped polymer fiber film PAN / ZIF-8 was obtained;

[0055] Put the fibrous membrane PAN / ZIF-8 in 1~3g L -1 Fe(NO 3 ) 3 in methanol solution, soaked for 3 hours and then vacuum-dried to obtain PAN / ZIF-8 / Fe adsorbed by metal ions, followed by heat treatment at a heating rate of 2-10°C / min, with a rate of heating ≥ 500°C, and keeping for 1-5h to obtain Nitrogen-doped carbon nanofibers NP-Fe supported by metal carbide nano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com