Door-window group-corner connection profile and glue injection method thereof

A technology for connecting profiles and group corners, which is applied in the field of gluing technology, can solve problems such as low utilization rate of glue liquid, enhanced product firmness, and influence on product service life, and achieves good gluing effect, easy operation, and high utilization rate of glue material. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, the present invention will be further described:

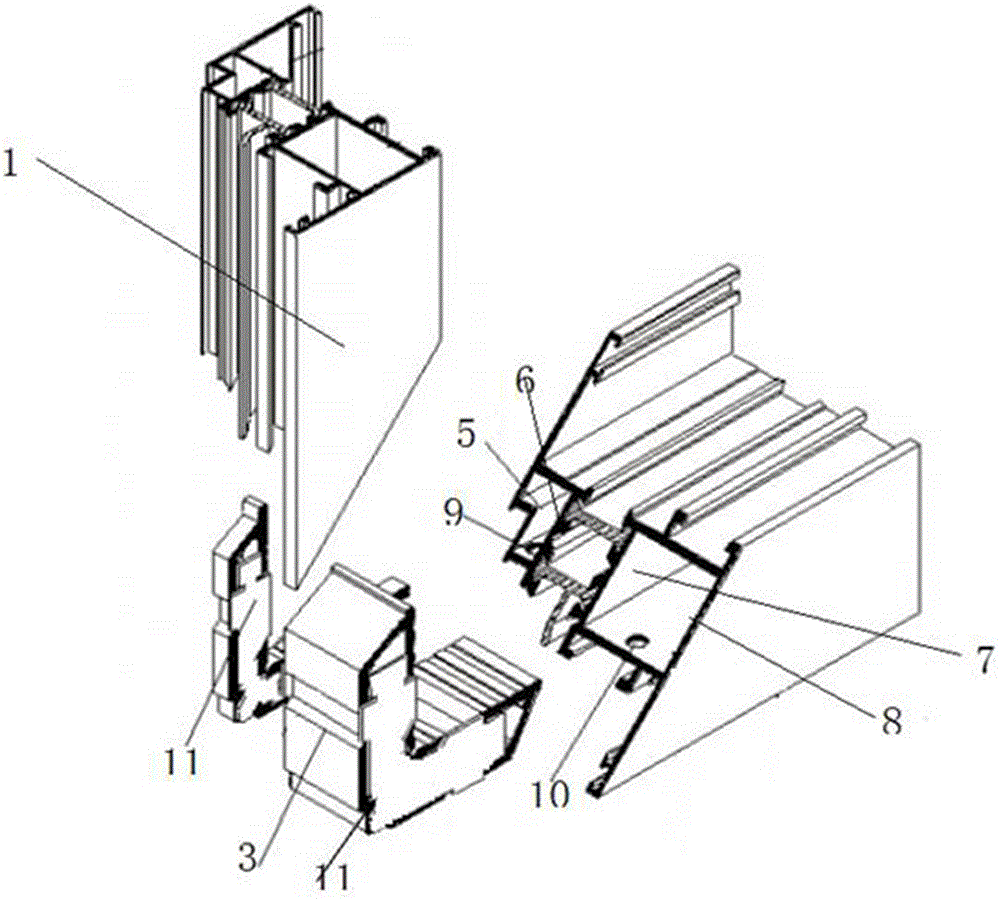

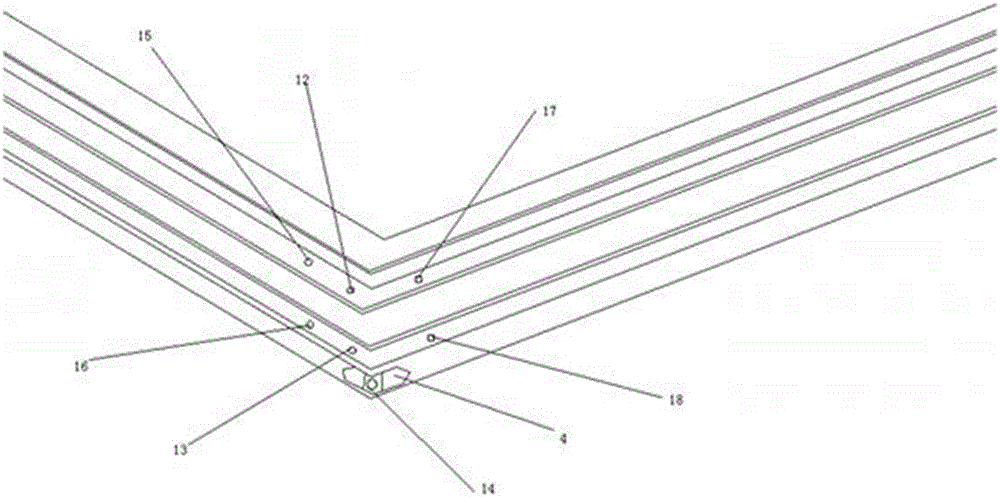

[0020] A door and window corner connection profile, including a mullion 1, a horizontal frame 2, a corner bracket 3 and a corner piece 4, the mullion 1 and the horizontal frame 2 respectively include an inner panel, an outer panel, a left side panel 9 and a right side panel 10, The inner panel is divided into a left inner panel 5 and a right inner panel 6, the outer panel is divided into an outer left panel 7 and an outer right panel 8, the outer panel, the left panel 9 and the right panel 10 jointly define a hollow structure, the mullions 1 and The hypotenuses of the connecting ends of the horizontal frame 2 are aligned and connected to form corners. The angles of the hypotenuses at the connecting ends of the horizontal frame and the vertical frame are generally 45 degrees, and there may be deviations in a small range, but the horizontal frame and the vertical frame The a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com