A CNC aluminum profile sawing machine

An aluminum profile and sawing machine technology, applied in the field of mechanical processing, can solve the problems of low sawing efficiency, rely on manual operation, and personal safety cannot be guaranteed, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

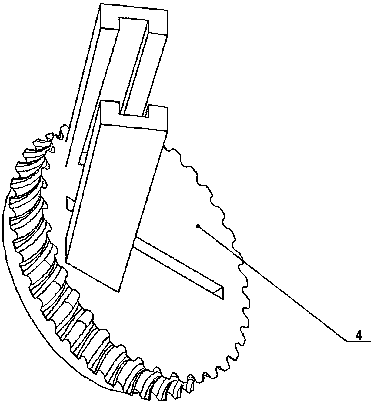

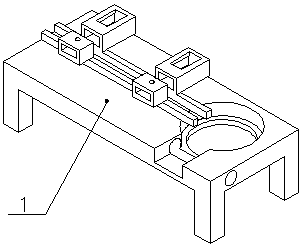

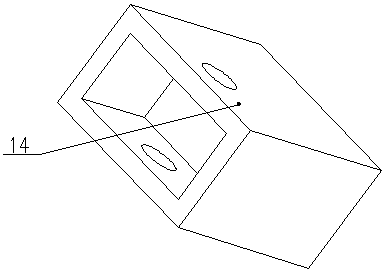

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a CNC aluminum profile sawing machine includes a base 1, a worm 2, a servo motor 3, a worm wheel turntable 4, a saw blade 5, a bevel gear driven wheel 6, a bevel gear driving wheel 7, a servo motor 2 8, Saw blade mounting block 9, baffle plate 10, screw mandrel 11, servo motor three 12, spring 13, spring mounting block 14, feeding driven wheel 15, servo motor four 16, aluminum profile 17, feeding driving wheel 18, is characterized in that: The worm 2 is installed in the cylindrical hole of the base 1; the servo motor-3 is fixed on the base 1, and its output shaft is connected with the worm 2; the worm gear 4 is installed in cooperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com