Clamp for performing point welding on two points on arc face of workpiece

A curved surface and workpiece technology, applied in the field of workpiece fixtures, can solve problems such as low welding efficiency, low production efficiency, and time-consuming, and achieve the effects of simple overall structure, low manufacturing cost, and convenient and fast positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

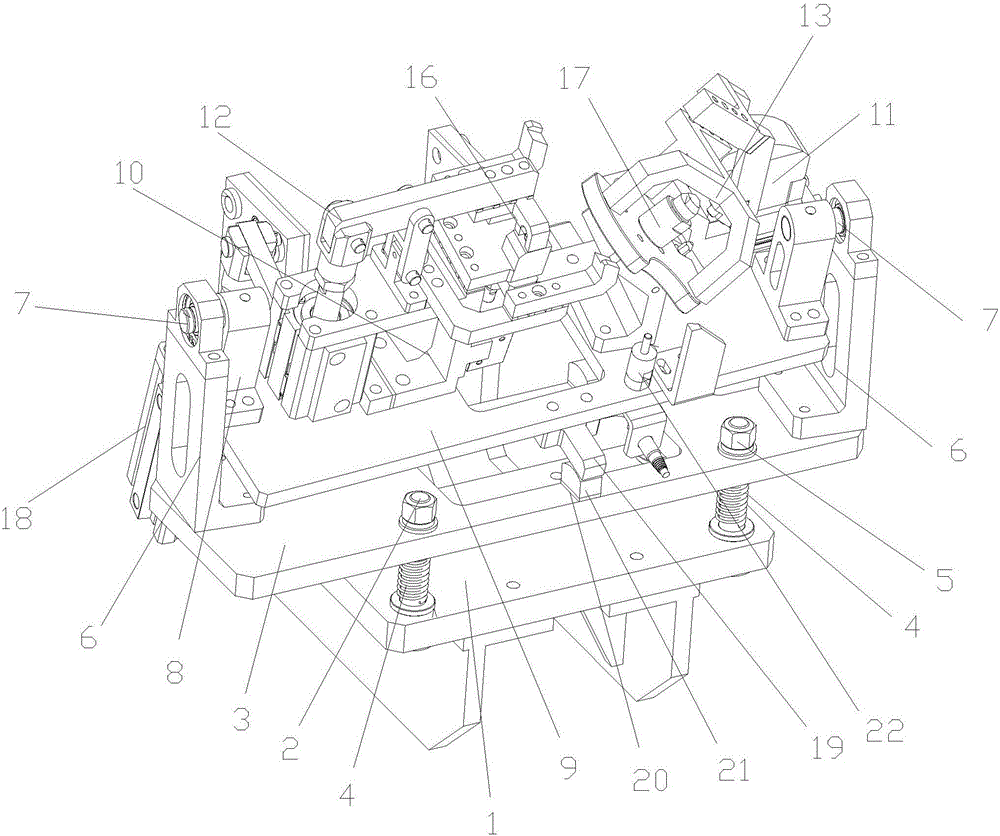

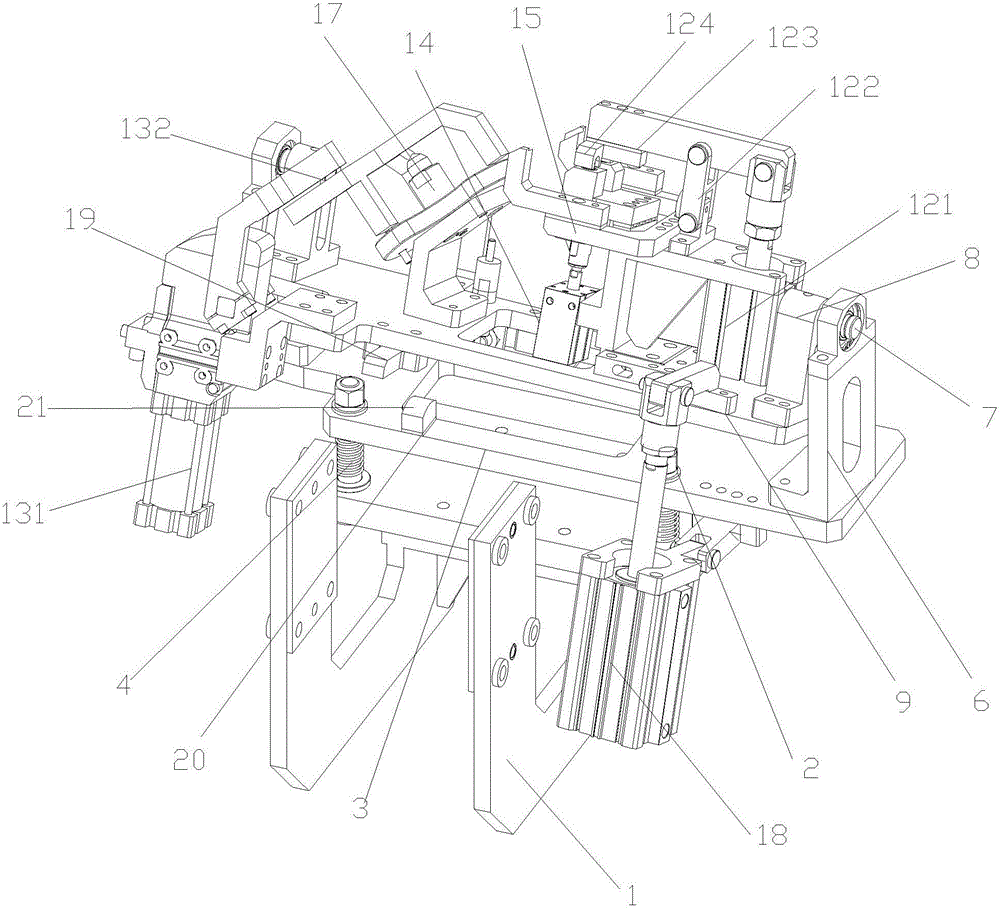

[0020] Such as Figure 1-2 As shown, a fixture for spot welding two points on the arc-shaped surface of the workpiece, including a connecting seat 1, four guide pillars 2 are arranged on the connecting seat 1, and a mounting platform is set on the four guide pillars 2 3. A spring 4 is sleeved on the guide post 2 between the installation platform 3 and the connection base, and the upper part of the guide post 2 is threaded with a lock nut 5 . Two mounting brackets 6 are relatively arranged on the mounting table 3, and the mounting shaft 7 is rotated in the mounting bracket 6, and the inner end of the mounting shaft 7 is covered with a bearing seat 8, and the bottom ends of the two bearing seats 8 are respectively connected to the movable plate 9. connected on both sides. The movable plate 9 is provided with a left mounting seat 10, a right mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com