A kind of steel wire belt stripping equipment

A technology of steel strip and stripping glue, applied in metal processing and other directions, can solve the problem of low efficiency, and achieve the effect of high cutting efficiency, reduced strength, and smooth cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

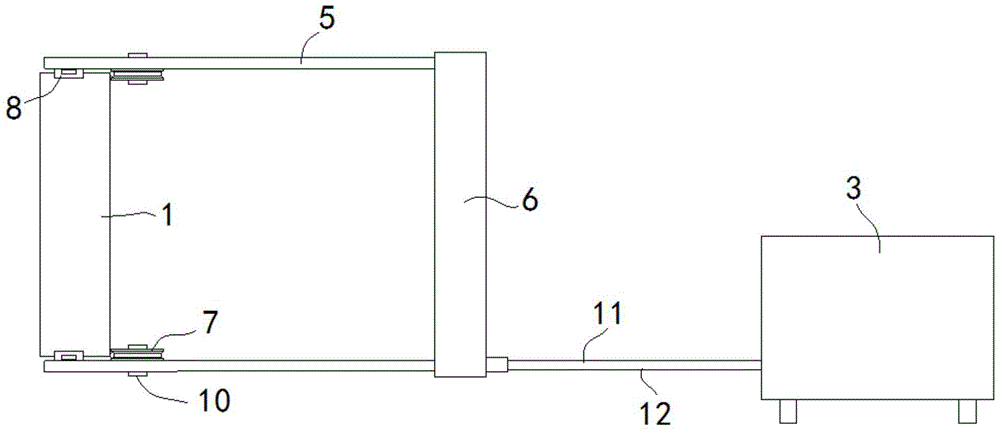

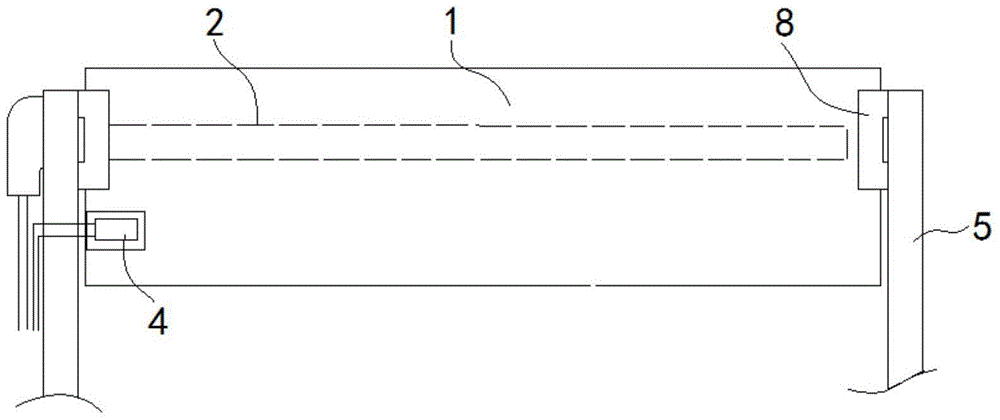

[0025] The rotating body is a roller 7 located on both sides of the plane blade 1, the center of the roller 7 is connected to the cage 5 in rotation, a sliding shaft 8 may be provided between the cage 5 and the plane blade 1, The planar blade 1 slides on the sliding shaft 8, and the sliding shaft 8 is fixed on the holder 5, so that the planar blade 1 can move up and down, thereby adjusting the distance between the planar blade 1 and the roller 7.

Embodiment 2

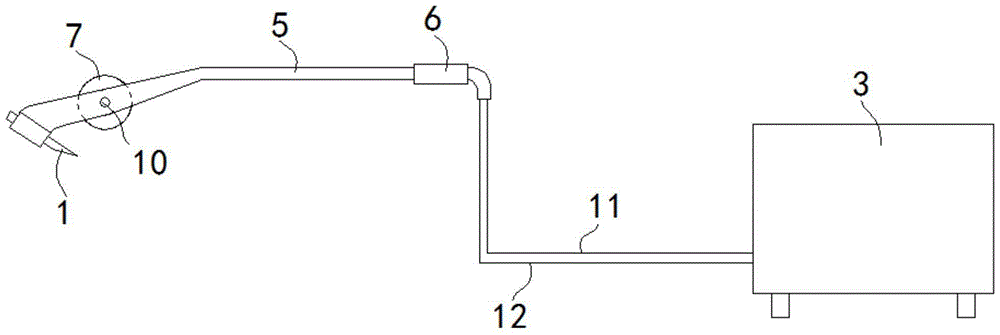

[0027] Such as Figure 4 As shown, the rotating body is a roller 9, and the center of the roller 9 passes through an optical axis 10, and both ends of the optical axis 10 are fixedly connected to the cage 5, and the cage 5 is provided with a long The holes enable the optical axis 10 to move up and down, thereby adjusting the distance between the roller 9 and the flat blade 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com