Double-surface thicknessing machine

A planer, double-sided technology, applied in the field of planing machinery and double-sided planers, can solve the problems of insufficient space for planers, difficult disassembly and assembly, etc., and achieves simple and novel structure, convenient disassembly and maintenance, and improved replacement speed and assembly. The effect of knife accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

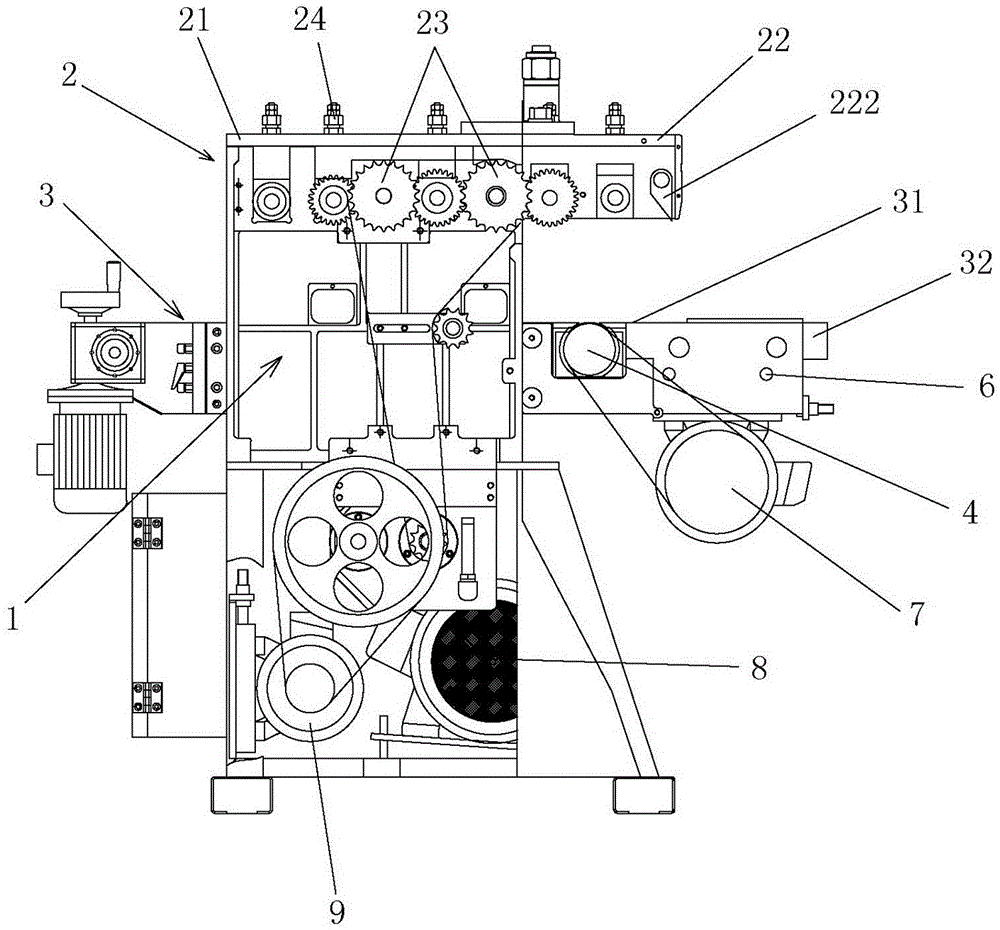

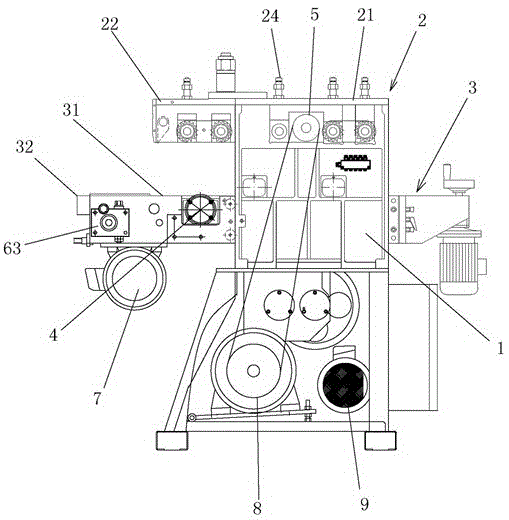

[0026] Example 1: Such as Figure 1-2 As shown, a double-sided planer includes a frame 1, a fixed table 2 and a lifting table 3. The frame 1 is fixed relative to the ground, the fixed platform 2 is installed on the upper part of the frame 1, the lifting platform 3 is installed on the frame 1 in a liftable manner, and the lifting platform 3 is located below the fixed platform 2.

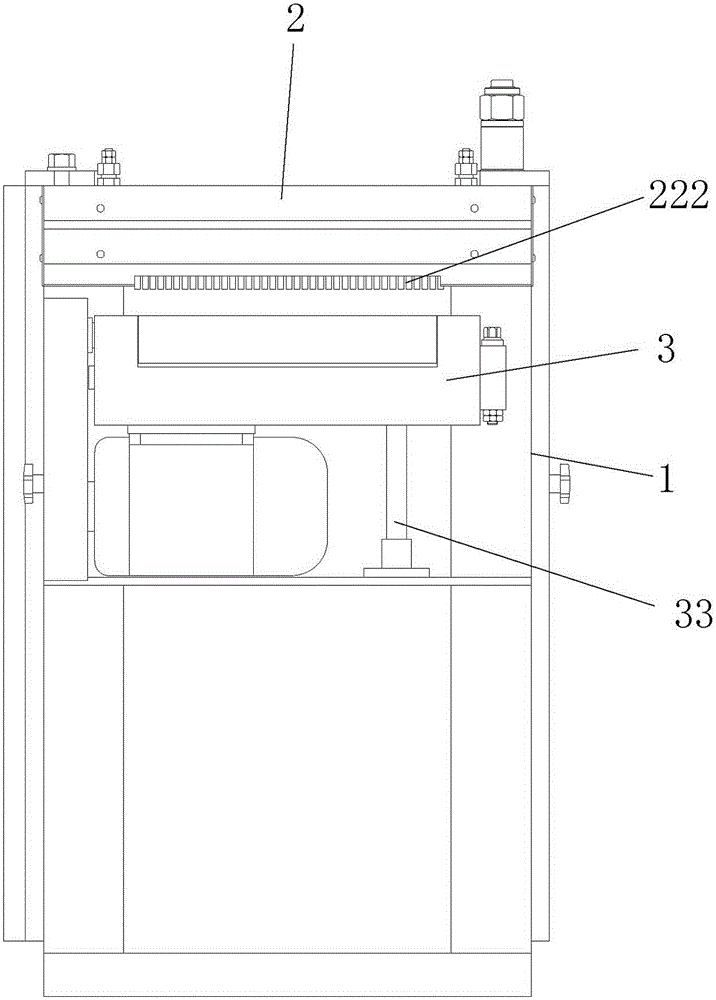

[0027] Specifically, the lifting platform 3 is lifted as follows: image 3 As shown, the bottom of the lifting platform 3 is provided with a lifting mechanism 33, which includes a lifting motor, a lifting screw and a screw nut. The reduction motor drives the lifting screw to rotate in a controlled manner, so that the screw nut drives the lifting platform 3 to lift.

[0028] Such as figure 1 As shown, the lifting platform 3 is provided with a lower planing knife 4, which is driven to rotate by a first driving motor 7 fixed on the lifting platform 3.

[0029] Such as figure 2 As shown, the fixed table 2 is p...

Embodiment 2

[0038] Embodiment 2: Basically the same as Embodiment 1, the following planing knife 4 is set on the lifting platform 3 and located below the rotating table 22; the difference from Embodiment 1 is that the fixed table body 21 and the rotating table 22 are hinged The shaft is connected, so that the rotating table 22 can be opened or flipped open relative to the fixed table body 21, similar to a book. When the rotating table 22 is turned over, an operating area is formed above the lower planing knife 4, so that there is sufficient operating space when the lower planing knife 4 is disassembled and assembled.

Embodiment 3

[0039] Embodiment 3: Basically the same as embodiment 1, the following planing knife 4 is set on the lifting table 3 and located below the rotating table 22; the difference from embodiment 1 is that the fixed table body 21 and the rotating table 22 are The ends of the connecting ends are all provided with connecting plates, and the connecting plate on the fixed table body 21 and the connecting plate on the rotating table 22 are fastened and connected by fasteners, thereby connecting the fixed table body 21 and the rotating table 22 into one body. When the lower planing knife 4 needs to be disassembled, first remove the fasteners on the connecting plate to separate the rotating table 22 from the fixed table body. At this time, an operation area is formed above the lower planing knife 4 to make the disassembly and assembly There is enough space for operation. Here, the rotating table 22 is not a rotating table, but it is simply called according to the situation to distinguish the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com