Soft tank for special sanitation truck

A special-purpose vehicle and sanitation technology, applied in the field of sanitation-specific vehicle tanks and boxes, can solve the problems of short service life, poor corrosion resistance, and vehicle weight, and achieve improved work efficiency, strong corrosion resistance, and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and a specific preferred embodiment.

[0033] In the present invention, the orientation words used such as "up, down, left and right" usually refer to the up, down, left and right shown in the accompanying drawings; "inside and outside" refer to the outline relative to each part itself inside and outside.

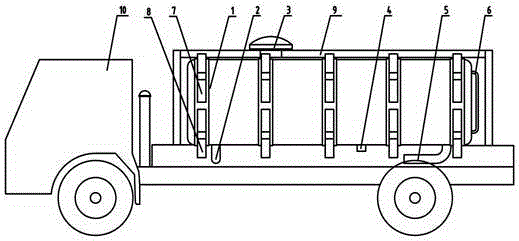

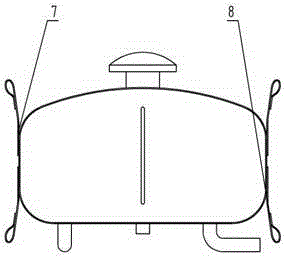

[0034] see as figure 1 , the present invention is applied to the sanitation sprinkler vehicle as the software tank of the main water tank of the sanitation sprinkler vehicle, comprising a tank body 1, a water inlet 2, an air vent 3, an overflow port 4, a water outlet 5, a water mark pipe 6, and a tank body lift Pull strap 7, tank body fixing strap 8, software tank fixing frame 9, chassis 10.

[0035] The tank body 1 is seamlessly made of low-density, corrosion-resistant polyurethane coated cloth; the water filling port 2 is fixed on the tank body 1, one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com