Platanus fruit hair fiber as preparation tio 2 Application of Micron Hollow Tube Formwork

A sycamore, hollow tube technology, applied in nanotechnology, nanotechnology, chemical/physical processes, etc., to achieve excellent catalytic performance, high purity, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Utilize the characteristic of above-mentioned plane tree fruit hair fiber, the present invention has provided a kind of TiO 2 The preparation method of microtube, the steps are as follows:

[0030] Put the plantain fruit hair fiber into a beaker containing absolute ethanol and soak for 1-2 hours. Take out the fiber and transfer it to another container filled with n-butyl titanate, TiCl 4 or TiBr 4 in a beaker, and stirred, so that the fibers fully contact with n-butyl titanate, TiCl 4 or TiBr 4 , and then let stand for 1-2 hours.

[0031] Take out from the beaker and soak in n-butyl titanate, TiCl 4 or TiBr 4 Put the fibers in the mixture into a beaker containing distilled water, and a white precipitate will be produced immediately. After stirring, let it stand for 1-2 hours, so that the reaction can fully proceed.

[0032] Take out the fiber, wash it 3 times with distilled water, and put it into an oven to dry. Calcinate the sample at 450-550°C for 2-3 hours in...

Embodiment 1

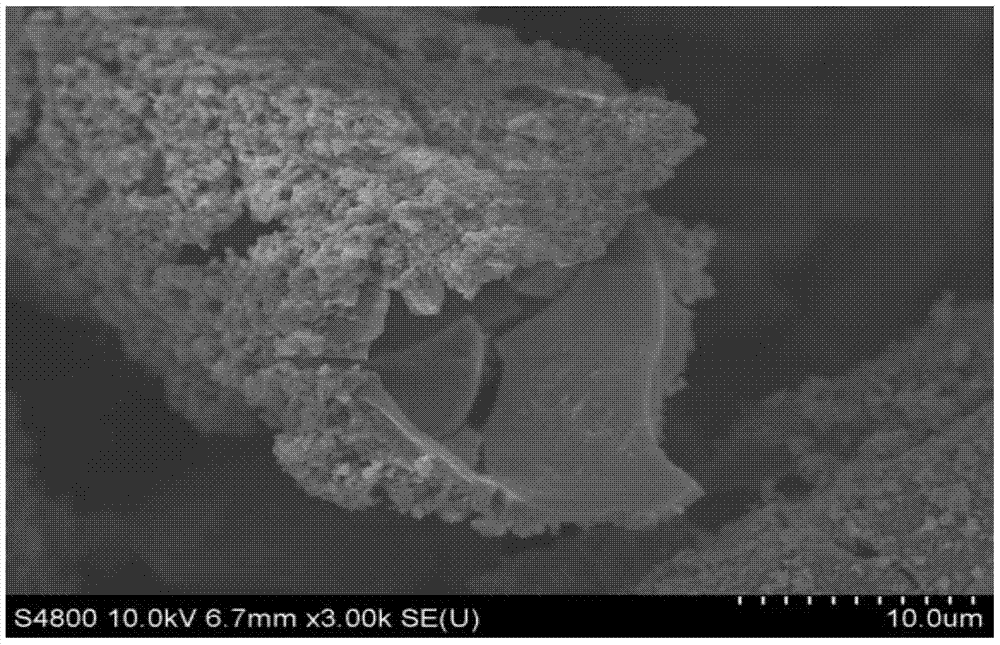

[0037] Wash the sycamore fiber with deionized water and ethanol, put the fiber in an oven at 60°C, and dry it. Weigh 0.5g fiber with an electronic balance, put it into a beaker containing absolute ethanol, and soak for 1 hour. The fibers were taken out, transferred to another beaker filled with n-butyl titanate, and stirred so that the fibers fully contacted with n-butyl titanate, and then left to stand for 2 hours. Take out the fiber soaked in n-butyl titanate from the beaker, put it into a beaker containing distilled water, a white precipitate is formed immediately, stir and let it stand for 2 hours to make the reaction fully proceed. The fibers were taken out, washed 3 times with distilled water, and dried in an oven. The sample was calcined in a muffle furnace at 500 °C for 2 hours to remove the fibers and obtain the desired TiO 2 micron tube.

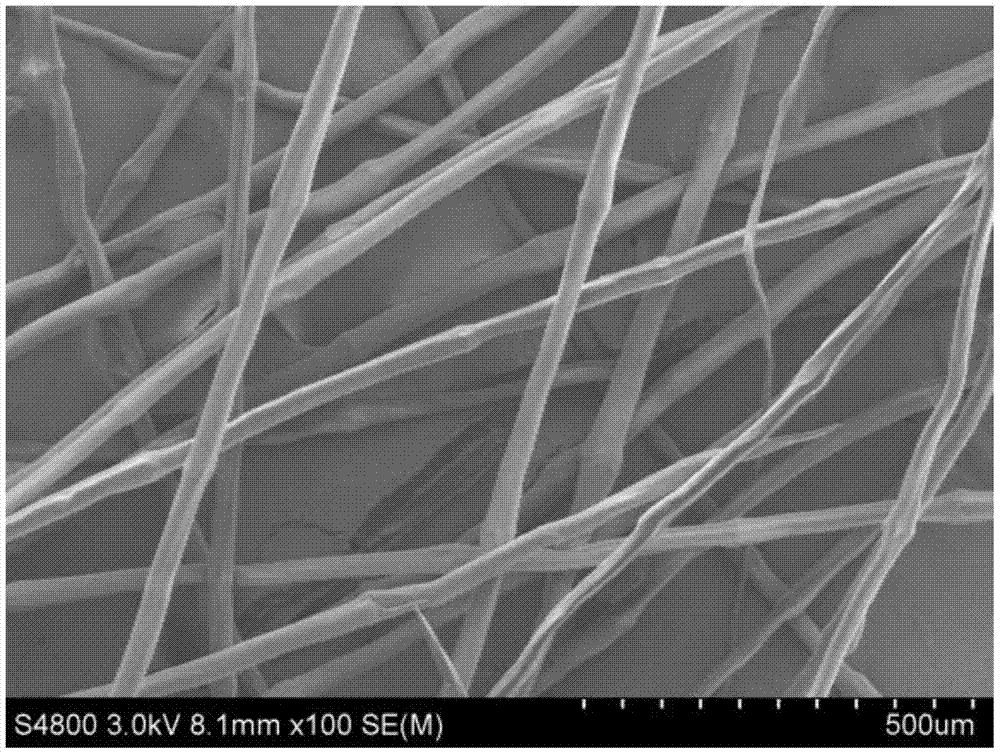

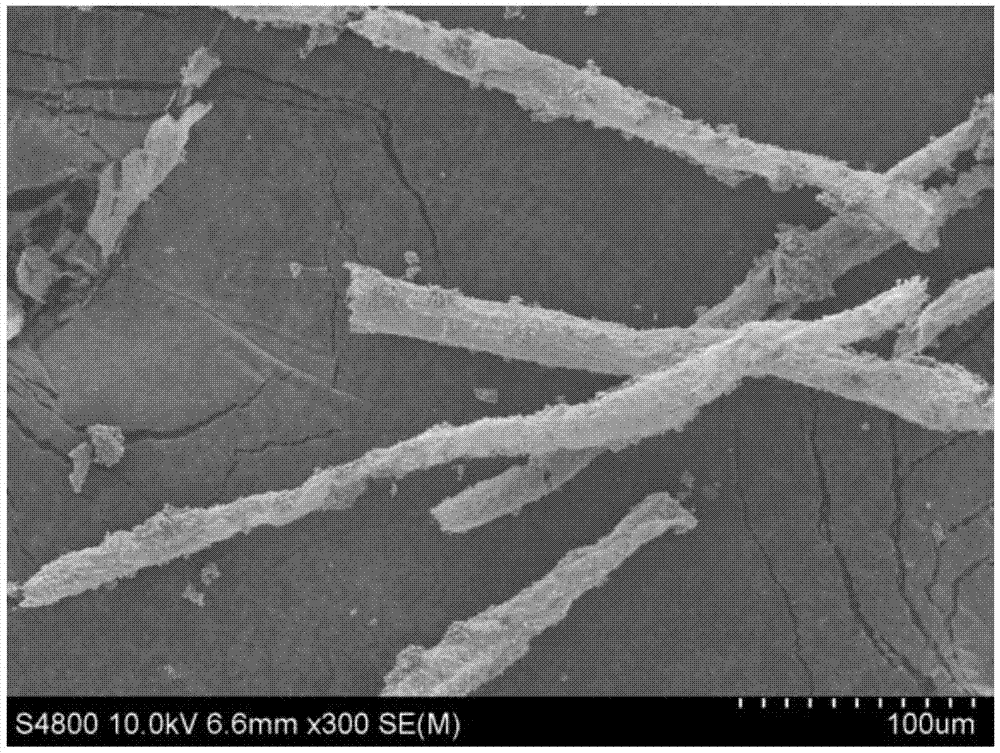

[0038] In this embodiment, the syringa fruit hair fiber is used as a biological template, and its appearance is as follows: ...

Embodiment 2

[0044] Wash the sycamore fiber with deionized water and ethanol, put the fiber in an oven at 60°C, and dry it. Weigh 0.5g fiber with an electronic balance, put it into a beaker containing absolute ethanol, and soak for 1 hour. Take out the fiber, transfer to another filled with TiCl 4 in the beaker, and stir to make the fibers fully contact with TiCl 4 , and then let stand for 2 hours. Remove from beaker and soak in TiCl 4 The fibers in the mixture were put into a beaker containing distilled water, and a white precipitate was produced immediately. After stirring, it was left to stand for 2 hours to allow the reaction to fully proceed. The fibers were taken out, washed 3 times with distilled water, and dried in an oven. The sample was calcined in a muffle furnace at 500 °C for 2 hours to remove the fibers and obtain the desired TiO 2 micron tube.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com