An in-situ reduction device and method for zinc cathode plates carrying electrolyte out of the tank

A cathode plate and electrolyte technology, which is applied in the direction of electrolysis process, electrolysis components, process efficiency improvement, etc., can solve the problem of electrolyte entering wastewater, reduce the amount and difficulty of wastewater treatment, improve economic benefits, and maximize The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

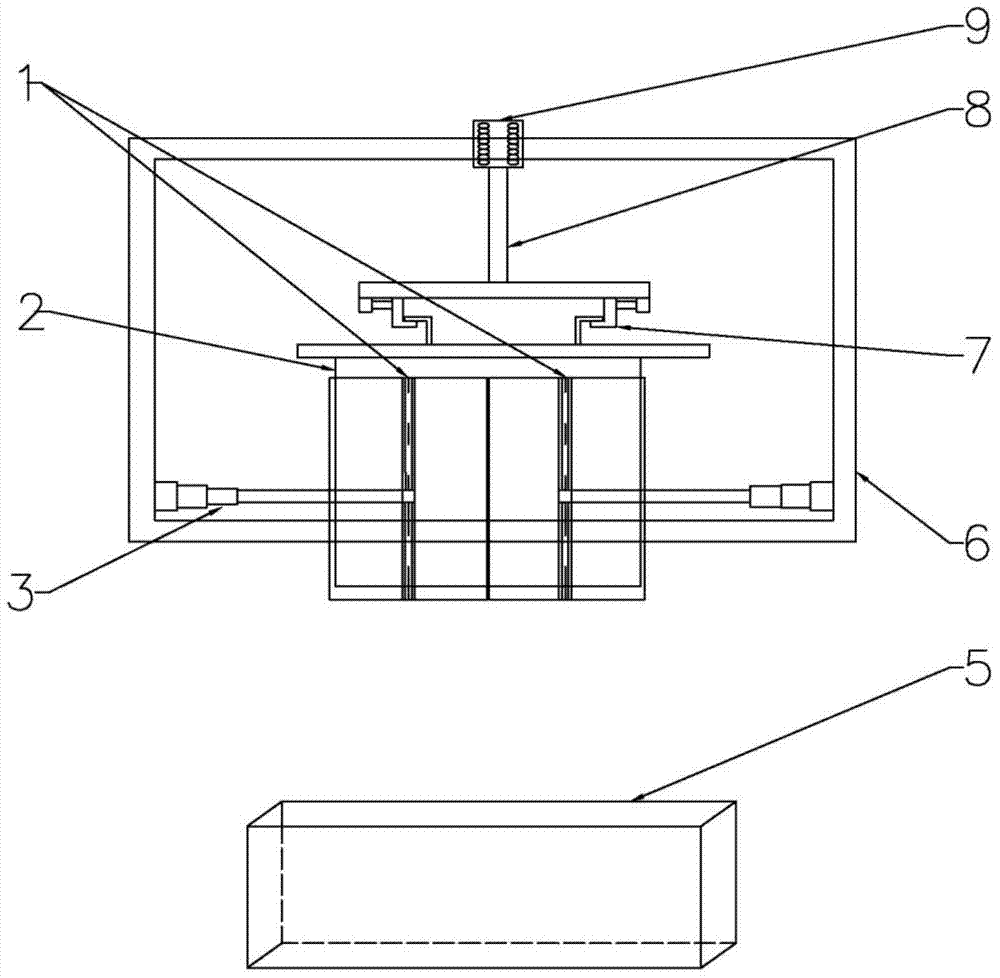

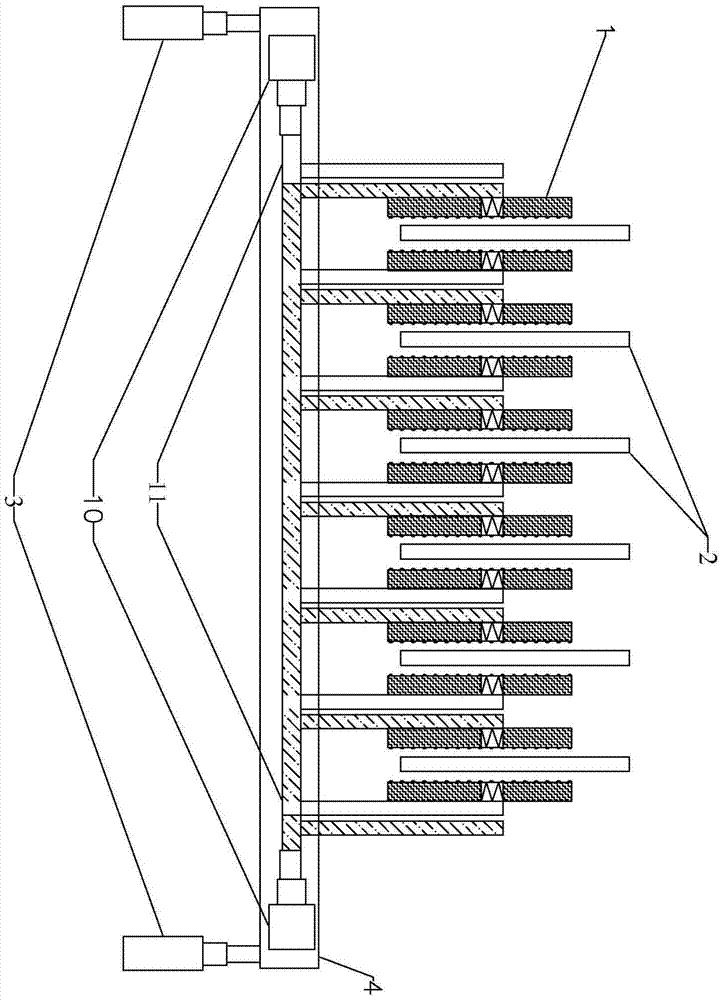

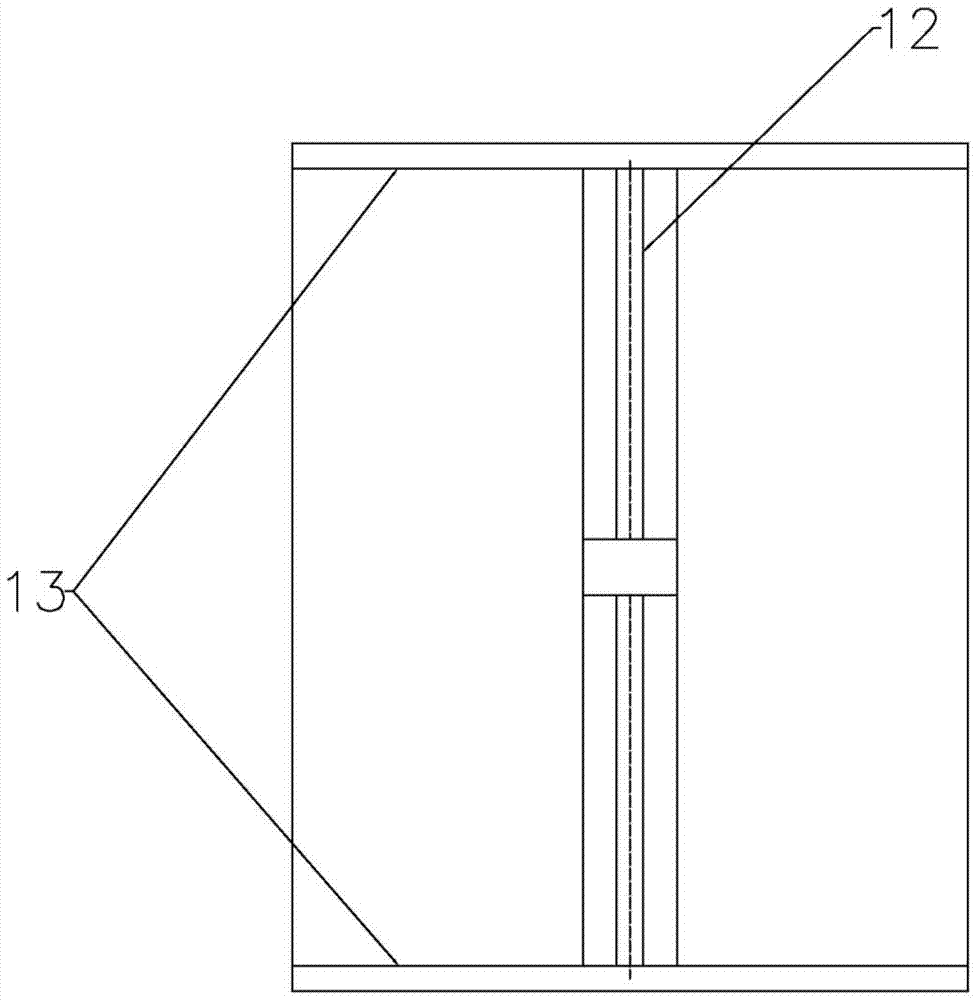

[0034] Such as Figure 1 to Figure 5 As shown, a method for in-situ reduction of electrolytic zinc cathode plate out of the tank with electrolyte, comprising the following steps:

[0035] 1) The cathode plate 2 is periodically electrolyzed in the electrolytic cell 5, and the metal substances contained in the electrolyte are reduced to tiny metal particles under the condition of being energized and deposited on the surface of the cathode plate 2 under the action of the electric field. One electrolysis cycle After the end, the tank outlet device is connected with the cathode plate 2, the tank outlet device clamps the cathode plate 2 and slowly lifts upward, the cathode plate 2 is lifted out of the electrolytic cell 5, and the surface of the cathode plate 2 carries a large amount of electrolyte;

[0036] 2) When the exiting device lifts the cathode plate 2 from the electrolytic cell 5 by 20-25cm, it stays for 5-6 seconds. During the stay of the cathode plate 2, the cylinders 3 lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com