Anti-mite fabric care composition and application method thereof

A technology of fabric care and composition, which is applied in the fields of fiber treatment, textiles and papermaking, and can solve the problems of weakening and weakening the effect of mite removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0098] A kind of anti-mite fabric care composition, it is made of following raw material components, and raw material composition list can be seen as shown in following table 1:

[0099] The anti-mite fabric care composition of table 1 embodiment 1~6 its raw material component (unit: percentage by weight %)

[0100]

Example 1

Example 2

Example 3

Example 4

Example 5

Example 6

2.0

0.8

0.1

---

---

---

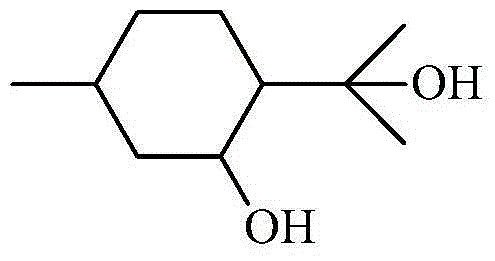

Menthiol

---

---

---

2.0

0.8

0.1

CO40

2.0

1.5

0.5

2.0

1.5

0.5

PHMB

0.8

---

---

0.8

---

---

BHA

---

0.2

---

---

0.2

---

TCC

----

---

0.1

----

---

0.1

essence

0.1

0.2

0.1

0.1

0.2

0.1

6

5

2.0

6

5

2.0

[0101] water

To 100

To 100

To 100

To 100

To ...

Embodiment 7~12

[0108] A kind of anti-mite fabric care composition, it is made of following raw material components, and raw material composition list can be seen as shown in following table 2:

[0109] Table 2 Embodiment 7~12 its raw material component of anti-mite fabric care composition (unit: percentage by weight %)

[0110]

[0111] TEP88 is provided by Solvay, and Bardac208-ME is provided by Lonza.

[0112] The preparation technology of embodiment 7~8 is as follows:

[0113] 1) Add process water to the batching pot according to the ratio in Table 2, then add Bardac208-ME raw materials, and start stirring;

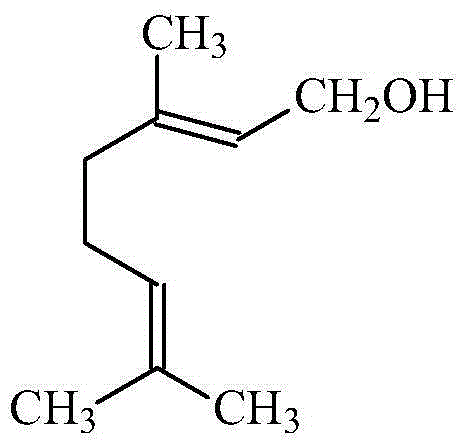

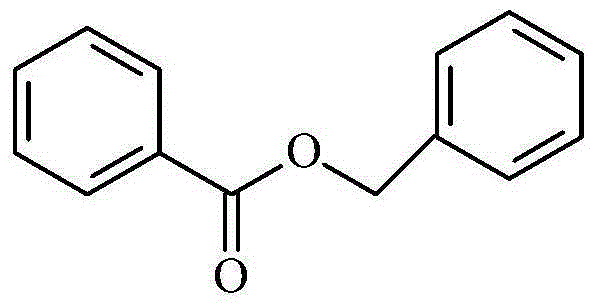

[0114] 2) Mix the oil-soluble raw material benzyl benzoate / triclosan / essence with surfactant and propylene glycol evenly;

[0115] 3) Add the mixture obtained in step 2) into the batching pot and stir evenly.

Embodiment 9

[0116] The preparation process of embodiment 9 is as follows:

[0117] 1) Mix benzyl benzoate with TEP88, heat to 45°C, stir and mix evenly;

[0118] 2) Add process water to the batching pot according to the ratio in Table 2, start stirring, and heat up to 45°C;

[0119] 3) Add the mixture of benzoic acid and TEP88 into the batching pot and disperse evenly;

[0120] 4) When the temperature of the batching pot drops to 35°C, add the essence and stir evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com