Rotation piston pump

A piston pump and rotary technology, applied in the field of rotary piston pumps, can solve the problems that the intake and exhaust valves cannot be set too large, increase dynamic load and bearing wear, increase mechanical vibration, etc., and achieve simple manufacturing, The effect of low production cost and large output energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

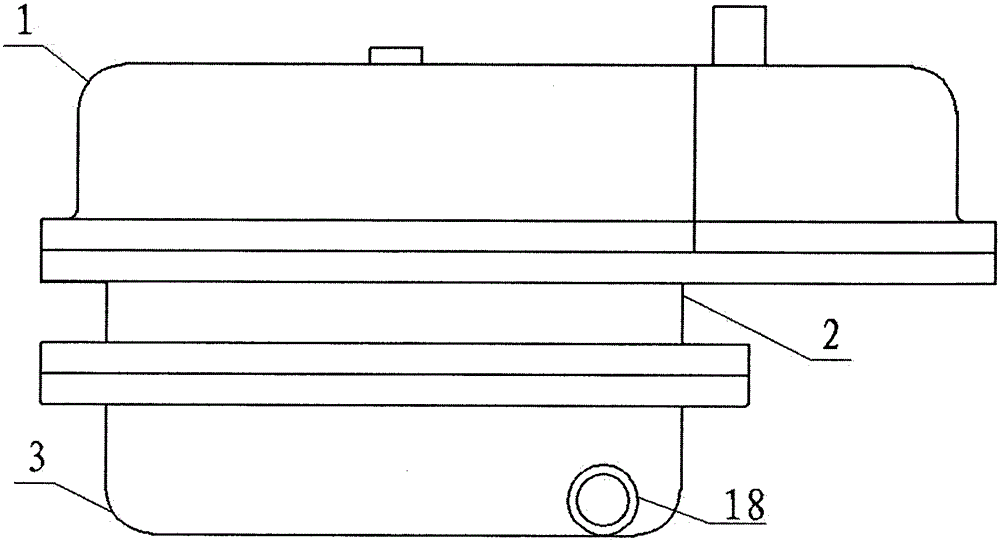

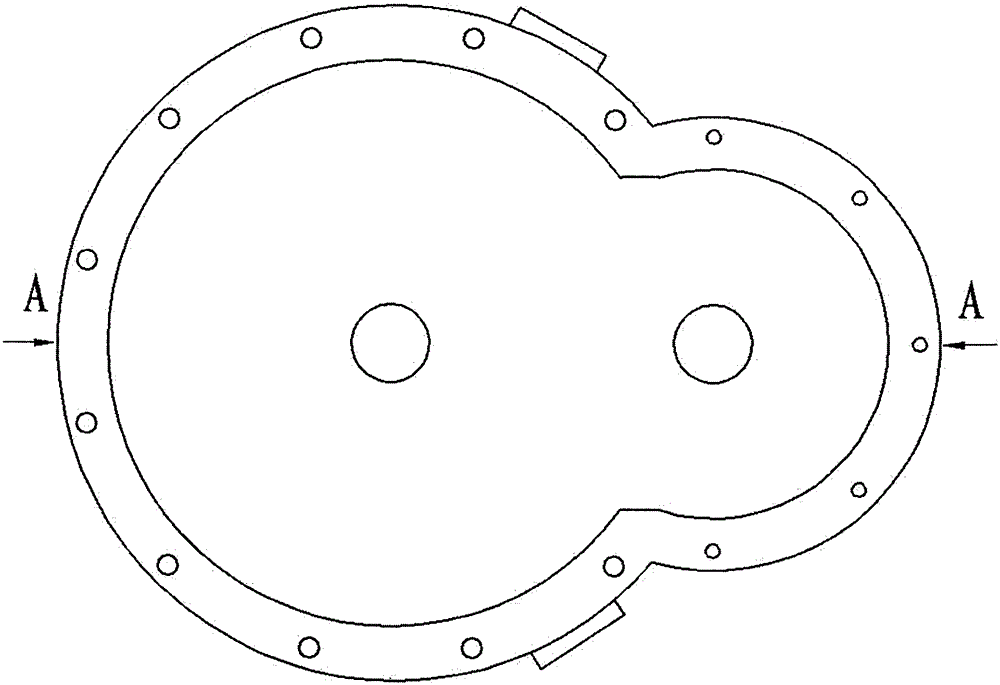

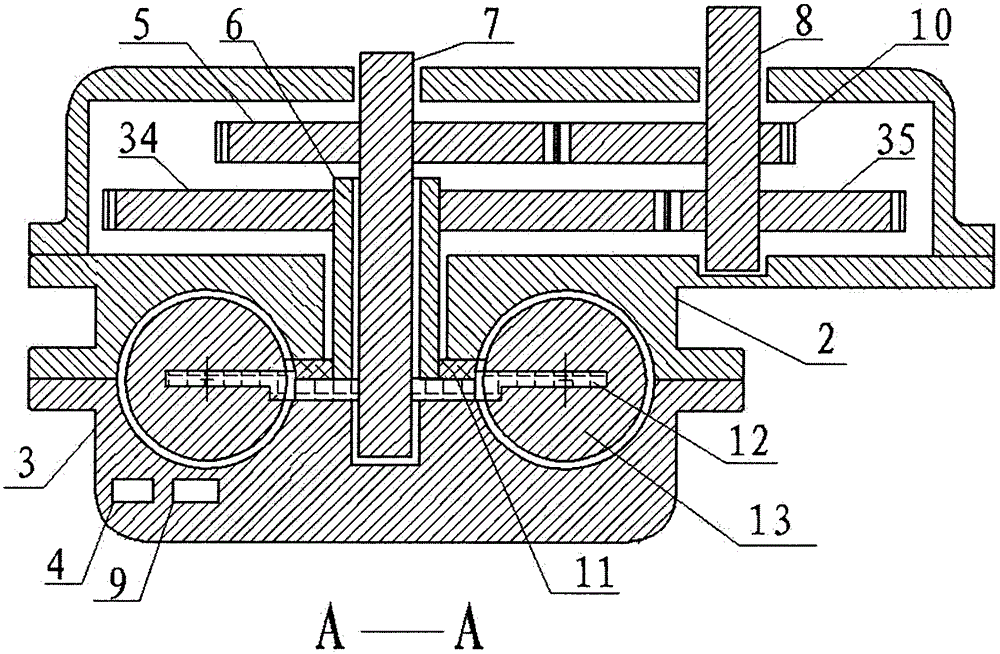

[0052] Implementation method 1: This structure includes two annular cylinders 2, 3 with semicircular inner sections to form a set of circular cylinders with a circular cross section, such as figure 1 , 2 , 3, 7, and 9; a sealing ring groove 33 is provided on the cylinder body where it contacts the rotor, such as Figure 7 , 9 Shown; Two rotors 11,12 are also housed in the cylinder body, the rotor is provided with seal block groove 24 and seal ring groove 25, seal block groove 24 inside is equipped with seal block 27, and seal ring groove 25,33 insides are all installed There is a sealing ring (not shown in the figure), and the sealing ring and the sealing block are provided with a spring function (not shown in the figure) to ensure the sealing effect; the rotor is equipped with rotor shafts 6 and 7, and the rotor shaft 6 is hollow and sleeved on the On the rotor shaft 7 and assembled with the rotor 11, the rotor shaft 7 passes through the rotor shaft 6 and the rotor 12 is as...

Embodiment approach 2

[0053] Implementation method 2: when acting on a liquid pump, the inner sections of the two annular cylinders 36, 37 can be set to be rectangular to form a set of annular cylinders with a rectangular section, and the four pistons 29 matched with them The cross-section is also rectangular, such as Figure 25 , 26 , Shown in 27 and 29; this implementation method does not need piston rings and lubrication mechanisms for piston rings; other than that, the others are the same as the implementation method one.

[0054] The working principle of this structure is as follows: it uses the difference in rotation angle between the two eccentric gears and the two non-circular gears to cause a difference in the rotation speed of the two rotors, so that the volume between the pistons changes, and the air intake and compression are completed. Exhaust is a coherent work procedure, its procedure is as follows Figure 14 , 20 , 24, 28, and 30, when setting and assembling, the non-circular gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com