Intermediate counter weight method for dynamic balance of elongated-shaft carbon fiber composite

A technology of composite materials and slender shafts, which is applied in the field of machining tooling to achieve the effect of solving deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below.

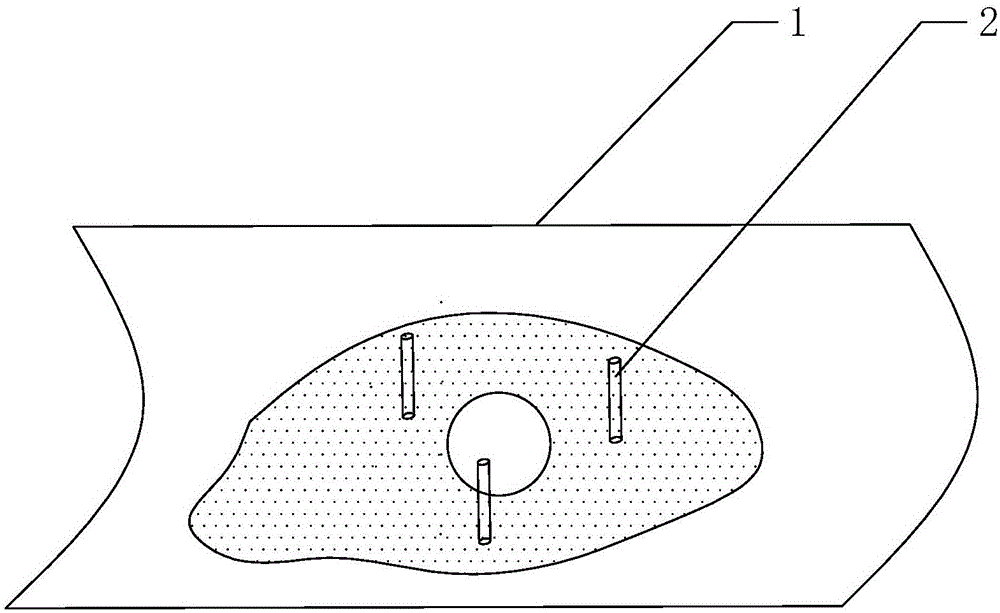

[0016] 1) Find the mechanical center of gravity of the slender shaft 1 through a dynamic balancing machine, and measure the counterweight;

[0017] 2) Use a 2mm drill bit to drill a hole at the center of gravity, then pour an appropriate amount of resin and iron powder into it for counterweight, and insert 1 to 3 small sticks 2 into the hole, which can act as a plug and penetrate deeply. In the carbon fiber roller, the role of fixed weight;

[0018] 3) Place the weighted slender shaft 1 horizontally with the hole facing down, and wait for the resin to solidify.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com