Flexible automatic sealing furnace door

An automatic sealing and furnace door technology, applied in the direction of furnaces, furnace components, lighting and heating equipment, etc., can solve the problems of lack of flexible buffer structure, furnace door deformation, loss of sealing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

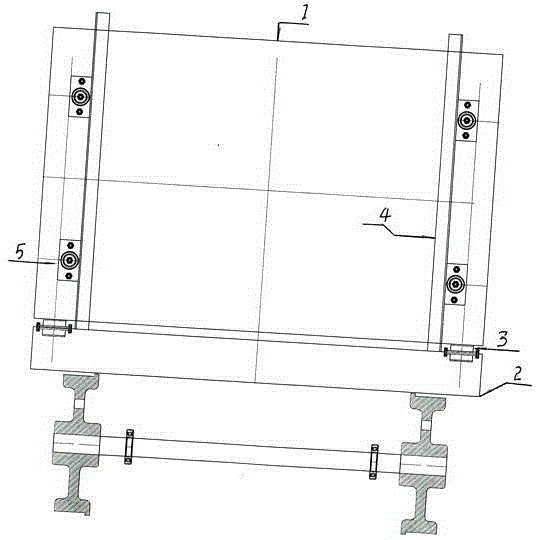

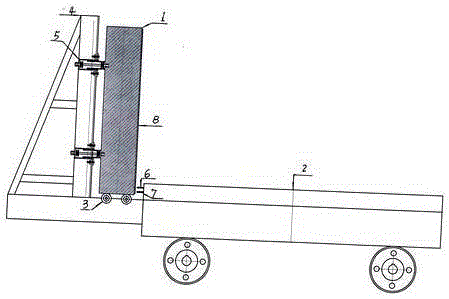

[0012] Specific examples figure 1 and figure 2 As shown, the furnace door 1 stands on the front part of the trolley 2, and the furnace door 1 and the trolley 2 are supported by two sets of sliding support wheels 3. The front end of the trolley 2 is welded with a fixed support frame 4, and the furnace door 1 The outer steel plate and the fixed support frame are connected by a flexible seal regulator assembly 5. The flexible seal regulator assembly has multiple functions such as guiding, buffering, pressing, and adjustment. Further, the flexible seal regulator is collectively referred to as It is composed of inner and outer guiding tubular sleeves, springs and adjusting bolt parts. The outer guide sleeve is installed on the outside of the inner guide sleeve, slidingly fitted, and mainly plays a guiding role in the direction of motion of the furnace door. The inner guide sleeve is equipped with a spring, and the spring extends into the outer guide sleeve, and the spring mainly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com