Blasting Method for Dome of Large Section of Tunnel

A large-section, tunnel technology, applied in blasting and other directions, can solve problems such as roof fall, poor stability of surrounding rock, falling blocks, etc., and achieve the effect of reducing consumption and small deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in detail below in conjunction with accompanying drawing:

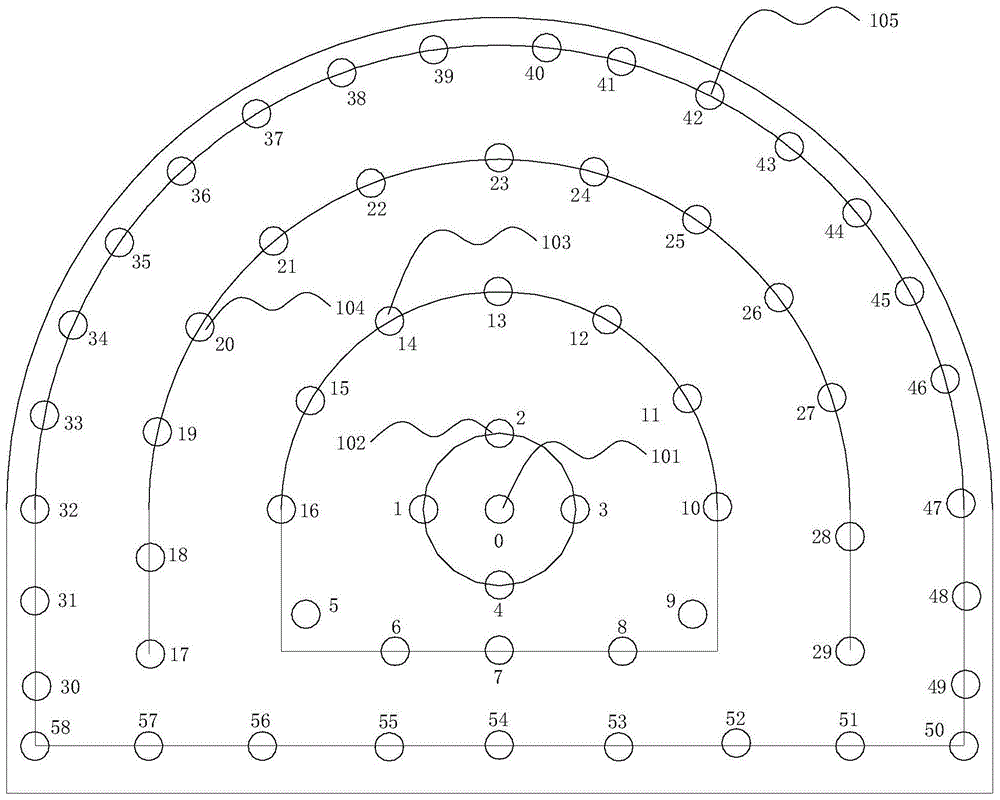

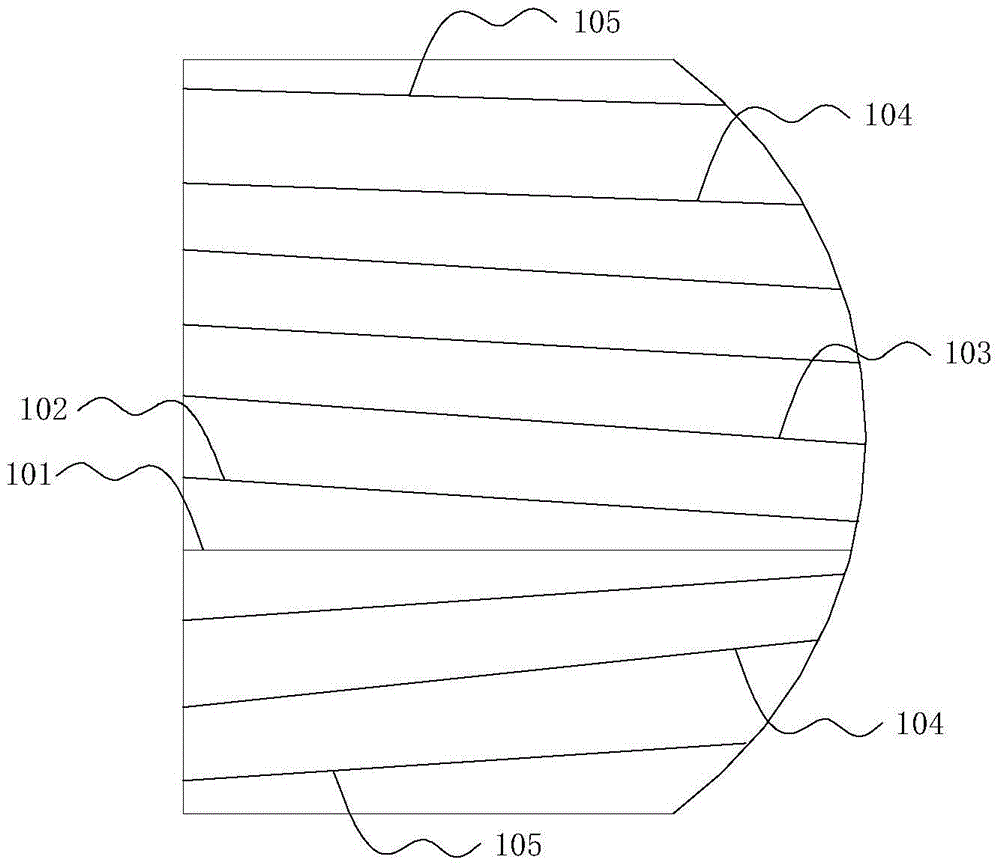

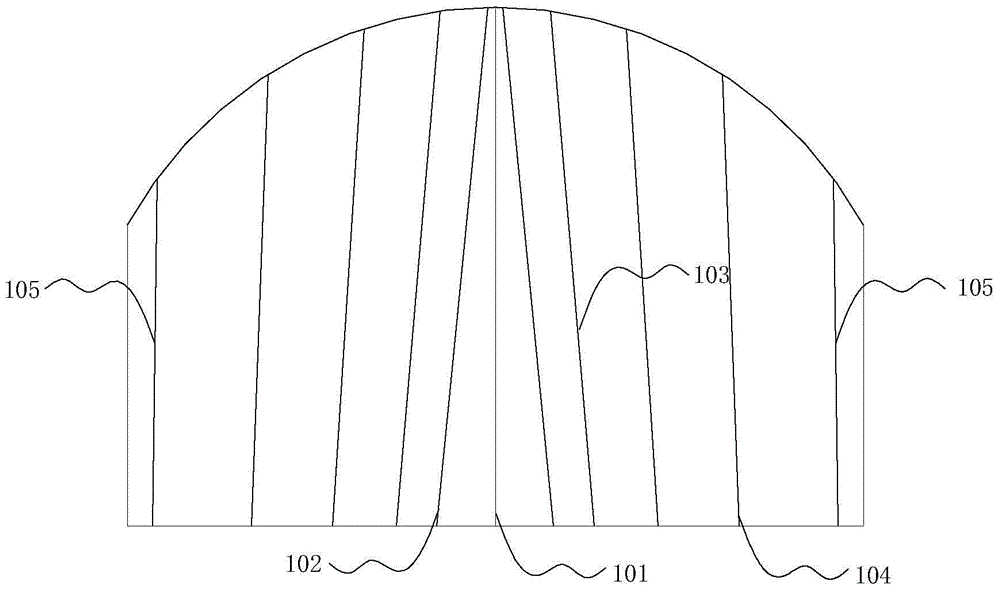

[0029] combine Figure 1 to Figure 3 , the blasting method in which the large section of the tunnel is formed into a dome,

[0030] The first step is to measure the excavation surface of the tunnel, determine the blasting center point 101 at a position 1 meter vertically downward from the geometric center point of the excavation surface, and drill a blasting center hole 101 at the blasting center point 101 along the axis of the tunnel. The above-mentioned blasting center hole 101 is the No. 0 hole shown in the figure, and the No. 0 hole is a straight hole along the axial direction of the tunnel.

[0031] In the second step, around the blasting center point 101, the positions of the cut eye group, the first auxiliary eye group, the second auxiliary eye group and the surrounding eye groups are sequentially determined on the excavation surface from the inside to the outside. Se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com