An online weighing bucket device for a ship unloader

A ship unloader and weighing bucket technology, which is applied to the field of ship unloader online weighing bucket devices, can solve the problems of vibration, increased grab bucket lifting height, and many equipment failure points, so as to reduce vibration and impact, ensure Work efficiency, the effect of preventing dust flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

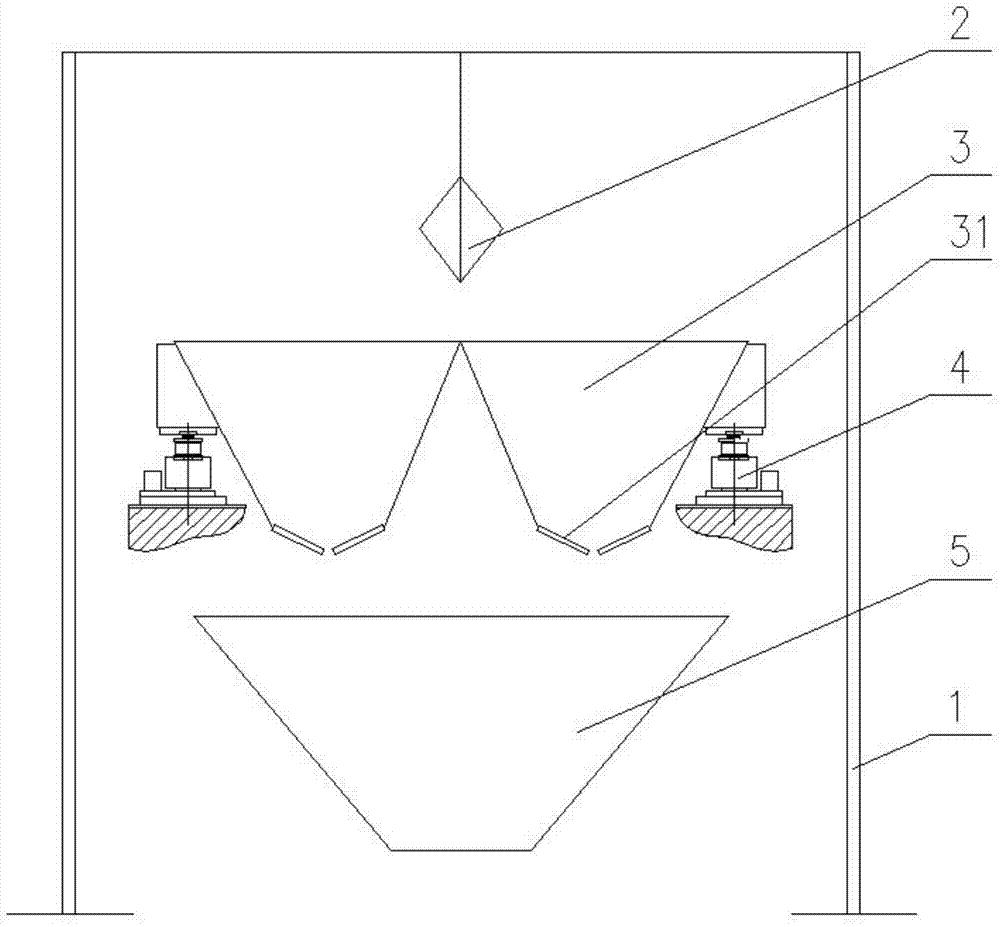

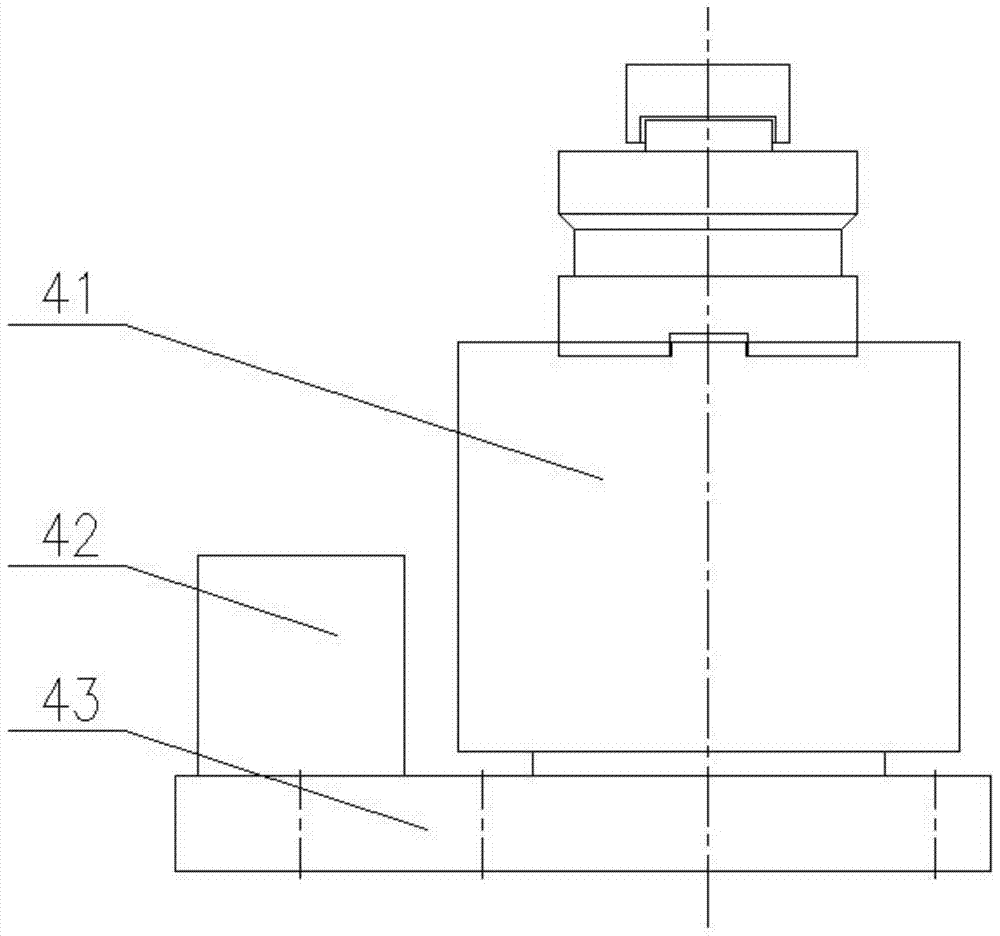

[0055] Embodiment 1: as figure 1 , figure 2 As shown, the present embodiment includes a ship unloading frame 1, a grab bucket 2, a metering bucket 3, a metering device 4, and a feeding hopper 5. The metering bucket 3 can be one or multiple components, and the metering bucket 3 includes a feed port 1, hopper door, the lower hopper is a discharge hopper 5, or there may be multiple ones, the metering hopper 3 is provided with a hopper door 31, the metering hopper 3 is arranged above the hopper 5, and the hopper door 31 is aligned with the hopper 5, so that the material is discharged from the metering hopper 3 Put into the discharge hopper 5, the metering device 4 is supported under the metering hopper 3, and is used to measure the weight of the material, including a main scale 41, an auxiliary scale 42, and a bottom plate 43. The main scale 41 is located below the side wall of the metering hopper 3, The auxiliary scale 42 is not in contact with the measuring bucket 3, and there...

Embodiment 2

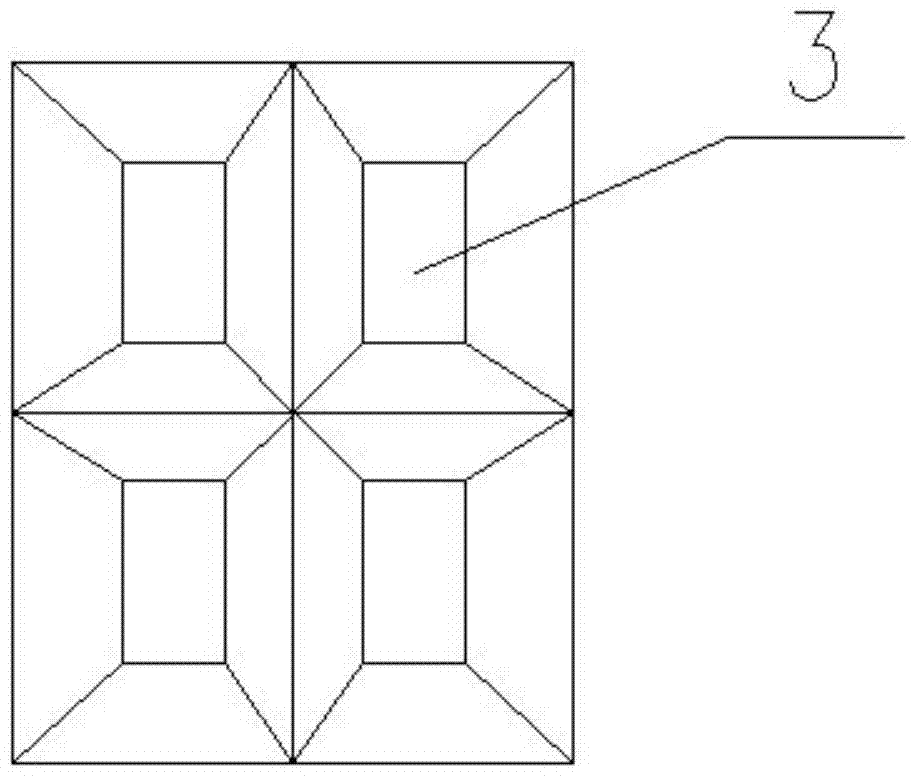

[0056] Embodiment 2: as image 3 Shown, present embodiment is on the basis of embodiment 1, is provided with 4 metering hoppers 3 above the hopper, and 4 metering hoppers are fixed together to form a square cone, and their hopper doors 31 are all above the hopper, Each side of the quadrangular pyramid is provided with a metering device 4 .

Embodiment 3

[0057] Embodiment 3: as Figure 4 , Figure 5 As shown, in this embodiment, the bucket door 31 of the metering bucket 3 is a jaw bucket door, which is composed of two symmetrically arranged jaws 311, each jaw 311 is connected with an arc gear 312, and the two arc gears 312 Mesh with each other, when one jaw 311 is opened, the arc gear 312 will synchronously drive the other jaw 311 to open at the same time, which can make the bucket door 31 open faster, facilitate the material to fall down as soon as possible, and also make the opening and closing of the bucket door 31 easier Smooth, reducing vibration, the opening and closing of the jaw flap 311 can be realized by hydraulic drive, and the hydraulic drive is more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com