Circular ring type fiber bragg grating (FBG) temperature sensor and encapsulation method

A technology of temperature sensor and optical fiber grating, applied in thermometers, thermometers with physical/chemical changes, instruments, etc., to achieve low repeatability error, increase wavelength variation, and increase temperature sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with specific examples and accompanying drawings.

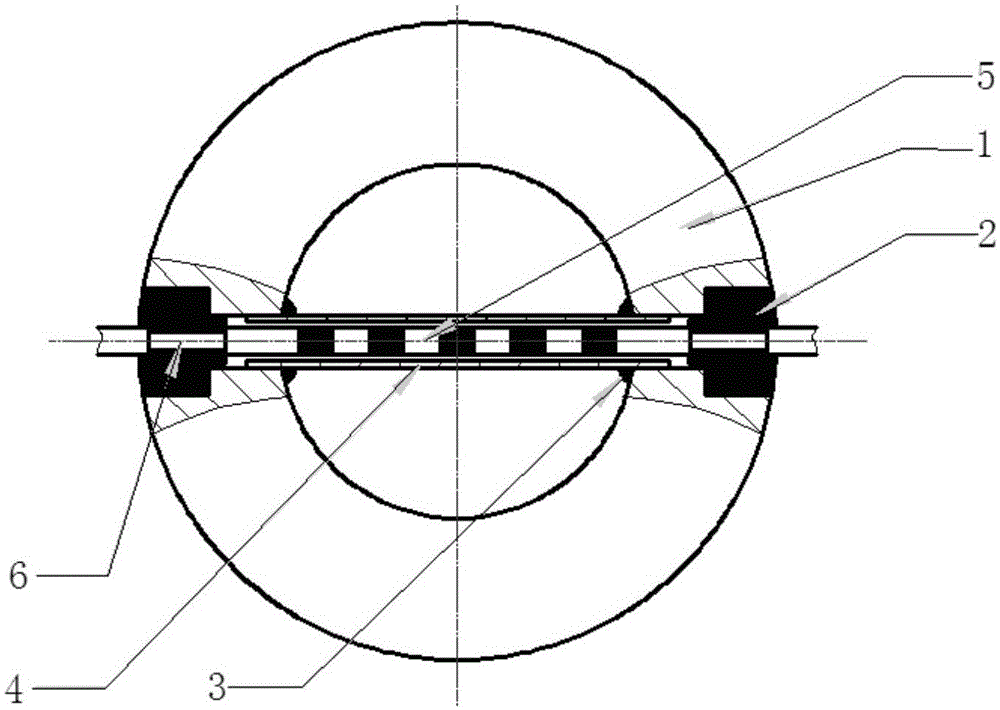

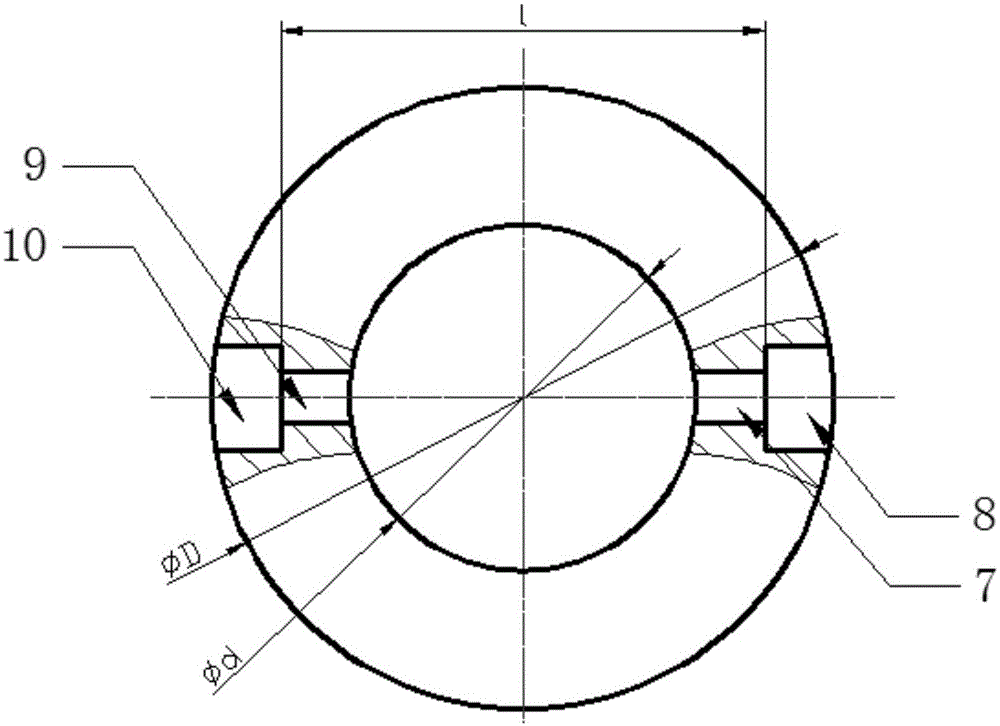

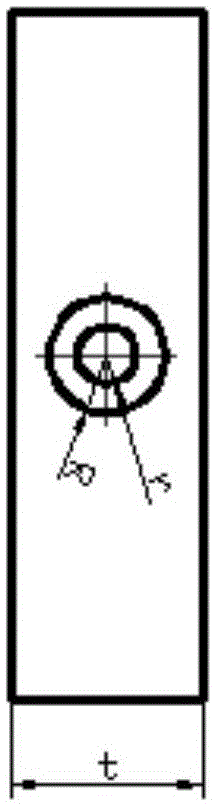

[0030] Such as Figure 1 to Figure 4 As shown, a ring-type optical fiber grating temperature sensor includes an optical fiber 11, a grating 5 is arranged on the optical fiber 11, and an elastic deformation body, the elastic deformation body is a ring 1, and through holes 9 are arranged on both sides of the ring 1 And the blind hole 10, the upper and lower sides are pasted with metal sheets for packaging and heat conduction; the through hole 9 communicates with the blind hole 10, and the through hole 9 is covered with a capillary metal tube 4, and the capillary metal tube 4 and the ring 1 The inner wall is fixed (AB glue 3 is used for fixing in this embodiment), the optical fiber 11 is passed through the capillary metal tube 4, and the grating 5 on the optical fiber 11 is located in the center of the ring 1, and the blind hole 10 is filled with glue fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com