Device and method for 360-degree bottle body production line front-light vision inspection

A detection device and assembly line technology, applied in the direction of optical testing flaws/defects, etc., can solve problems such as low space utilization, unsatisfactory, loose structure, etc., and achieve the effect of improving space utilization and compact and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the drawings and specific embodiments.

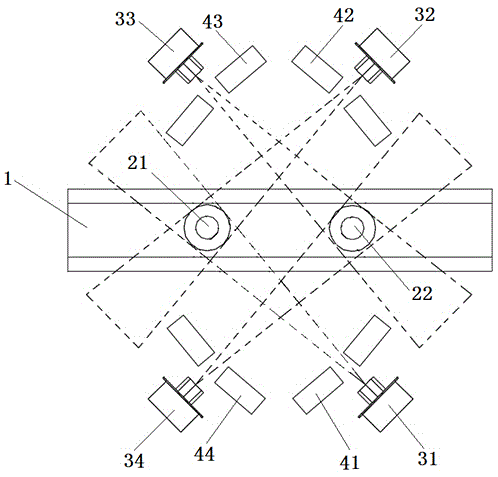

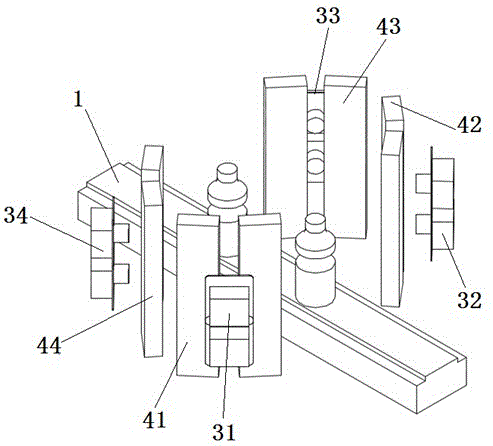

[0019] Such as figure 1 As shown, a 360-degree bottle body assembly line front light visual inspection device includes a first inspection station 21 and a second inspection station 22 arranged on an assembly line conveyor belt 1, and a second inspection station symmetrically distributed on both sides of the assembly line conveyor belt 1. A detection unit, a second detection unit, a third detection unit and a fourth detection unit. The first detection unit is composed of a first group of cameras 31 and a first group of light sources 41, the second detection unit is composed of a second group of cameras 32 and a second group of light sources 42, and the third detection unit is composed of a third group of cameras 33 and a third group. The light source 43 is constituted, and the fourth detection unit is constituted by a fourth group of cameras 34 and a fourth group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com