Multivariable process distillation column model prediction control optimization PID control method

A technology of model predictive control and control method, applied in the field of automation, can solve problems such as failure to achieve control performance indicators and control accuracy, difficulty in further improving the control level, and complex parameter tuning process, so as to improve control performance, improve control performance, Simple control structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] Take the example of a multivariate process called a distillation column:

[0080] Here we take the control of multiple variables in the distillation column as an example to describe, the situation in the distillation column is complex and may be affected by many different control variables at the same time.

[0081] Step (1). Establish the extended non-minimum state space model of the controlled object, the specific steps are as follows:

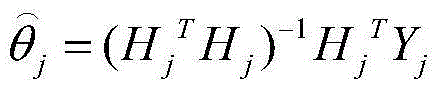

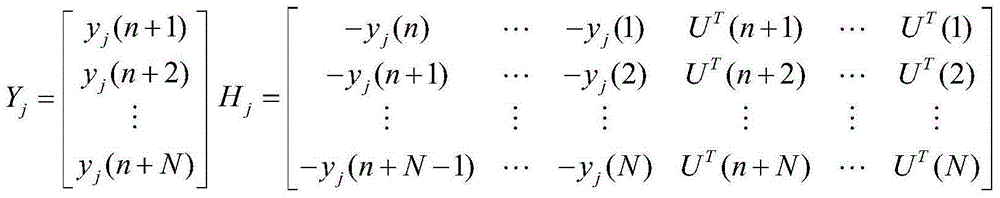

[0082] 1-1. By collecting the real-time data of the controlled object, use the least square method to establish the model of the multi-input multi-output system

[0083] Y(k)+H 1 Y(k-1)+…H n Y(k-n)=L 1 U(k)+L 2 U(k-1)+...+L n U(k-n+1)

[0084] in,

[0085] Y ( k ) = y 1 ( k ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com