A Physical Nesting Algorithm for Circular Parts

A technology of circular parts and algorithms, which is applied in calculation, electrical digital data processing, special data processing applications, etc., can solve the problems of time-consuming increase, inability to plan boards, and low utilization rate of boards, etc., to solve the problem of blanking and layout Problems, good adaptability, programming to achieve easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

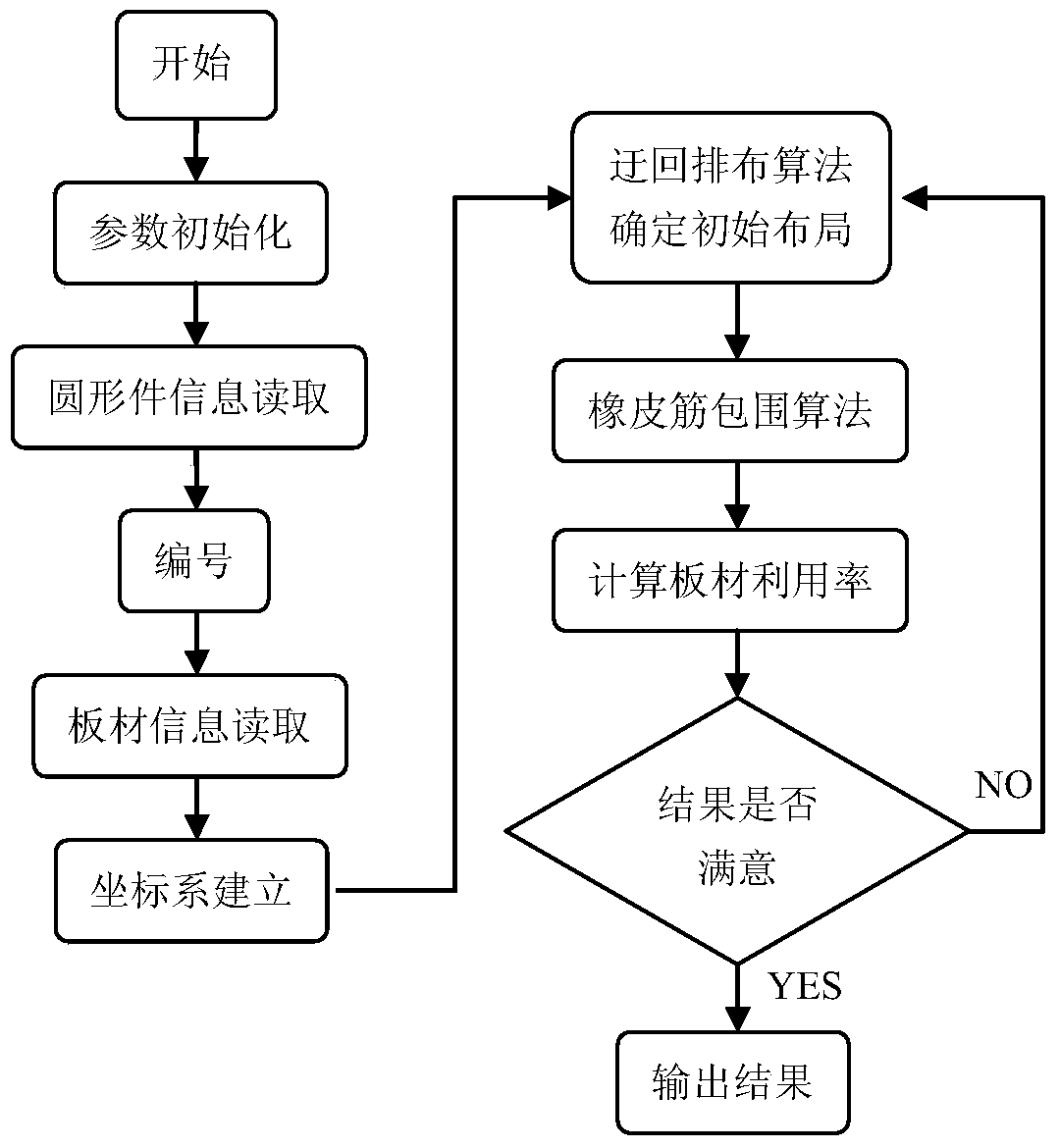

[0029] like Figure 1-Figure 3 As shown, a physical nesting algorithm for circular parts is carried out according to the following steps:

[0030] 1. Initialize the algorithm parameters, including the maximum number of iterations I and the convergence accuracy α;

[0031] 2. Read the radius r of the circular piece to be nested i and the corresponding quantity information n i , and number the circular pieces to be nested one by one, read the sheet width information w, and set the lower left corner point of the sheet as the coordinate origin (0,0), and the horizontal direction as the x-axis, and establish a Cartesian coordinate system;

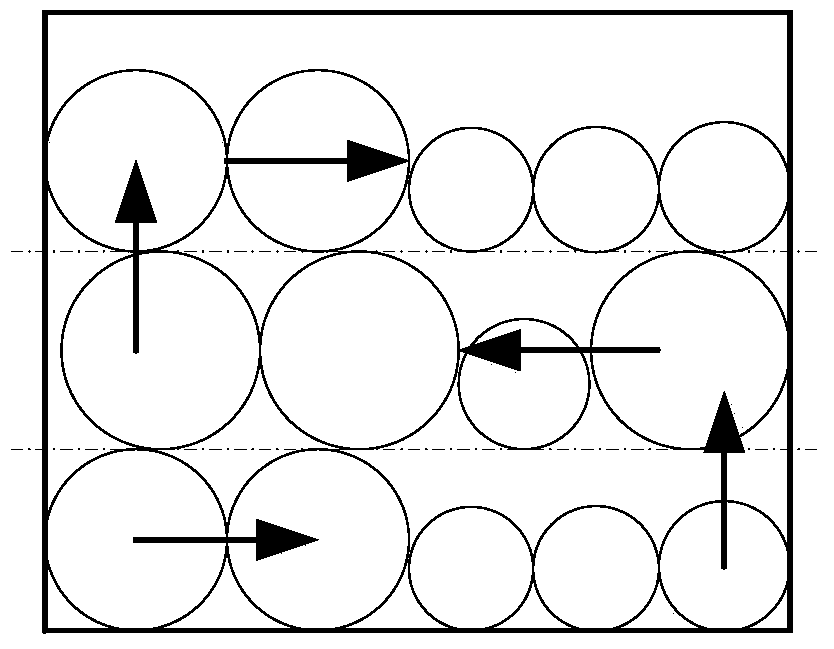

[0032] 3. Use a random method to scramble the numbered circular pieces, and place the corresponding numbered circular pieces in the plate according to the scrambled order using a circuitous arrangement algorithm;

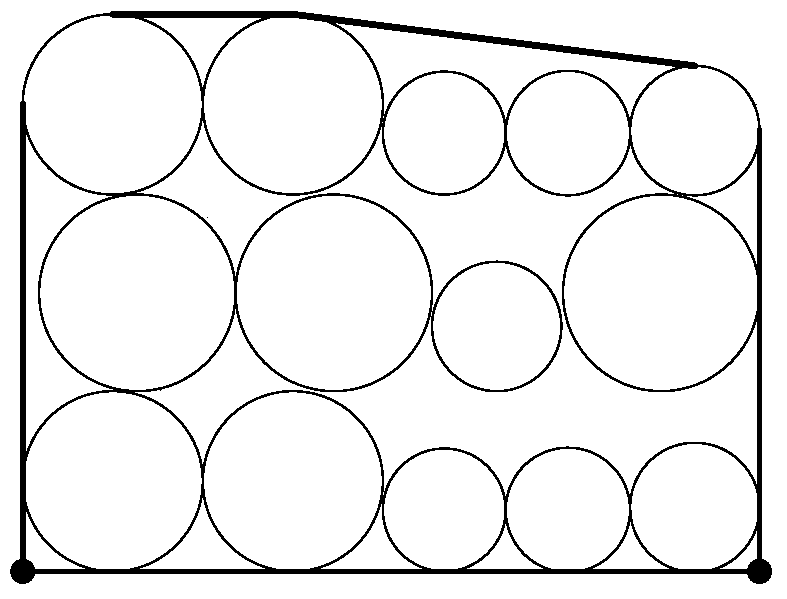

[0033] like figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com