Double-screen frequency selective surface capable of optimizing electromagnetic transmission characteristics

A technology of frequency selective surface and transmission characteristics, applied in circuits, electrical components, radiation unit enclosures, etc., can solve problems such as deterioration of passband performance, and achieve the effects of shortened processing cycle, simple structure, and excellent frequency response characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

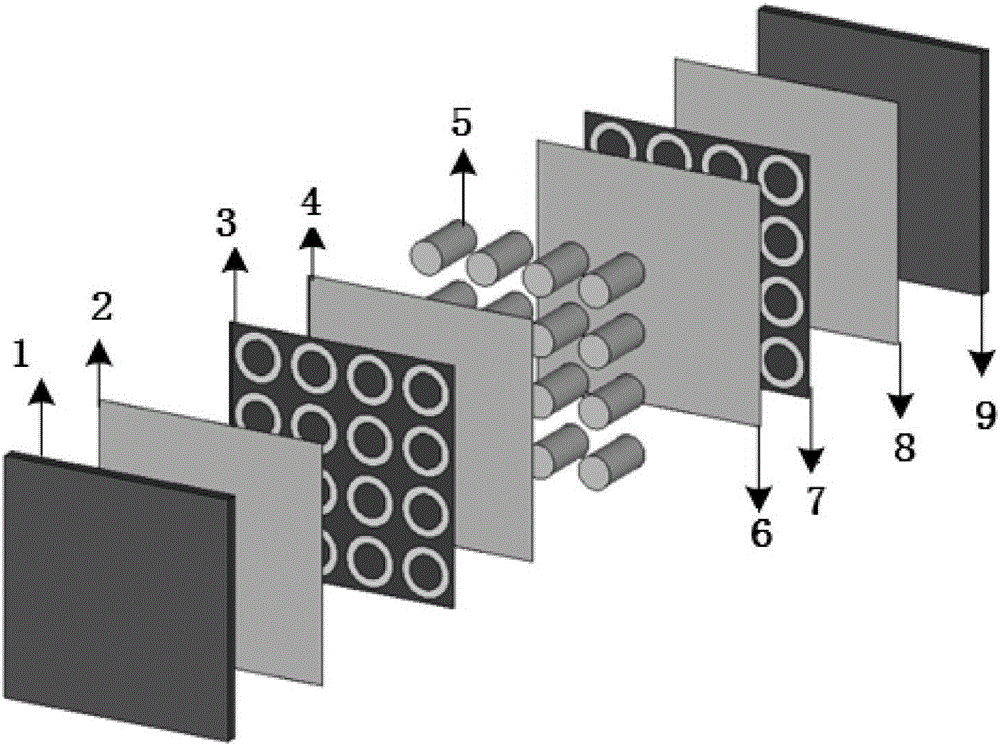

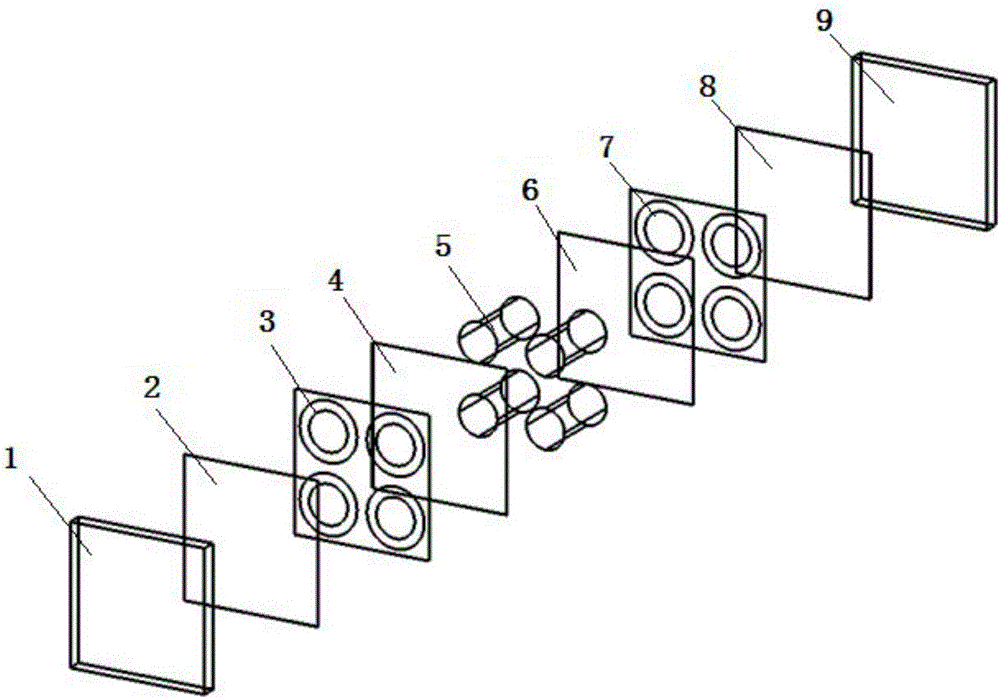

Image

Examples

Embodiment 1

[0041] Assuming that the passband is 7GHz±500MHz, the 0°-70° transmittance is required to be ≥85%, the stop band is 2GHz-4GHz, and the 0°-70° reflectance is required to be ≥90%. Next, how to implement the present invention will be shown by taking the technical index requirement as an example.

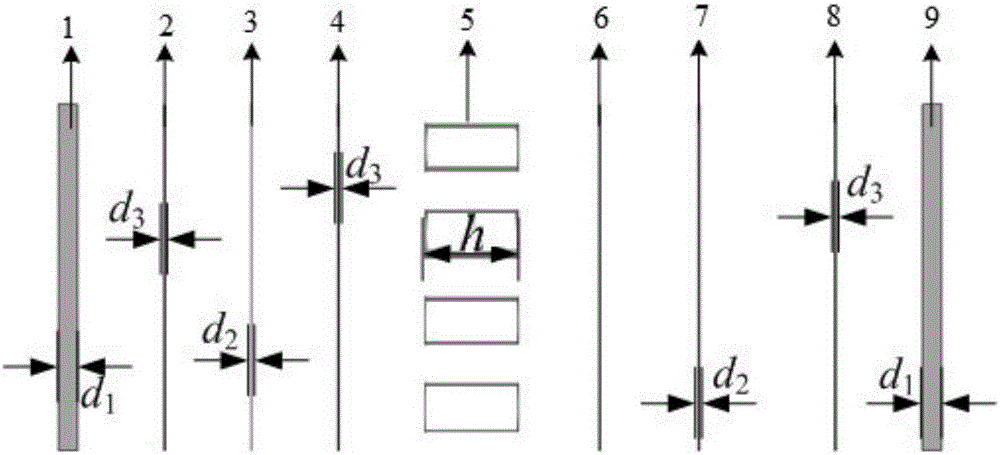

[0042] According to Munk and Mittra's research on FSS theory, it can be seen that the resonance size in the FSS pattern is consistent with the working wavelength λ. In order to verify the accuracy of the method, the first frequency selective surface layer 3 and the second frequency selective surface layer 7 adopt a simple Ring gap unit, its size satisfies λ≈2π(R in +R out ), where R in is the inner radius of the ring and R out is the outer radius.

[0043] Combined with the requirements of each layer, the structure of the dual-screen frequency selective surface for optimizing the electromagnetic transmission characteristics of Design Example 1 is as follows:

[0044] The thickness ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com